Preparation method of processed beef

A technology of beef and seasoning, applied in chemical preservation of meat/fish, food science, etc., can solve the problems of conditioning beef color, uneven flavor quality, short appearance time, etc., and achieve good antibacterial and anti-oxidation functions , Improve texture properties, improve water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

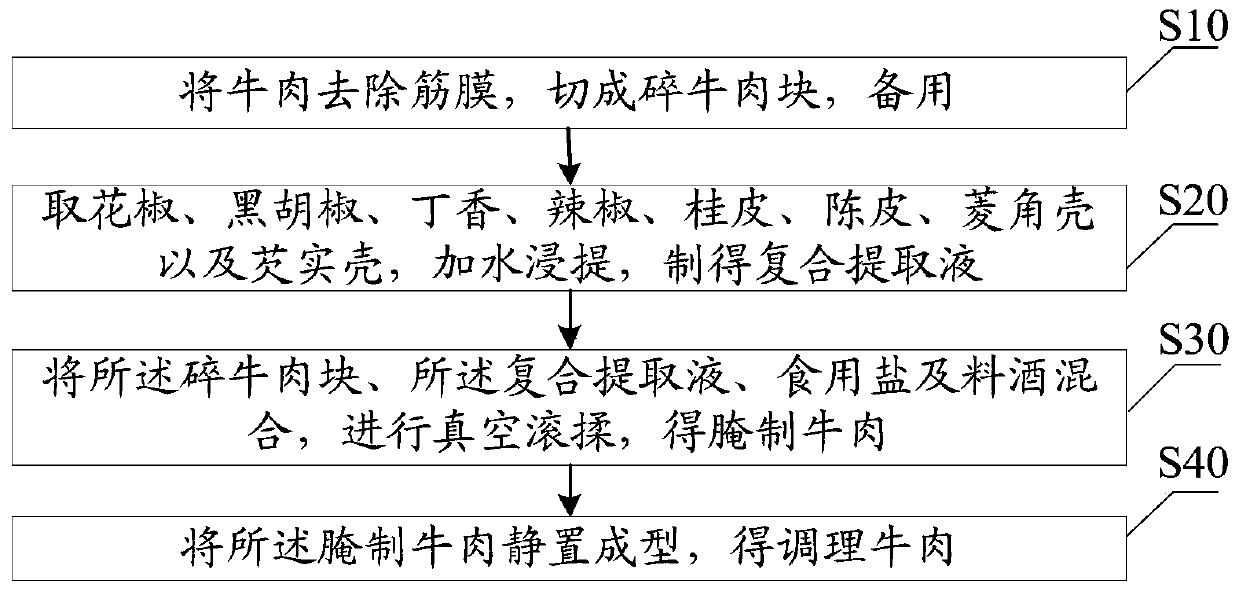

[0028] In view of this, the present invention proposes a preparation method of conditioned beef. The conditioned beef prepared by the preparation method has fresh and tender taste, attractive color and unique flavor. to combine figure 1 A schematic flow chart of an embodiment of the proposed conditioning beef preparation method, the preparation method of the conditioning beef comprises the following steps:

[0029] Step S10, remove the fascia from the beef, cut it into minced beef pieces, and set aside.

[0030] During specific implementation, thawed frozen beef or raw fresh beef can be selected, and the rear part of the beef is the best.

[0031] Step S20, taking Chinese prickly ash, black pepper, clove, pepper, cinnamon bark, tangerine peel, water chestnut shell and Gorgon seed shell, and adding water for extraction to obtain a composite extract.

[0032] Cloves are fragrant, spicy, rich in polyphenolic compounds, and have antibacterial effects on Escherichia coli and Stap...

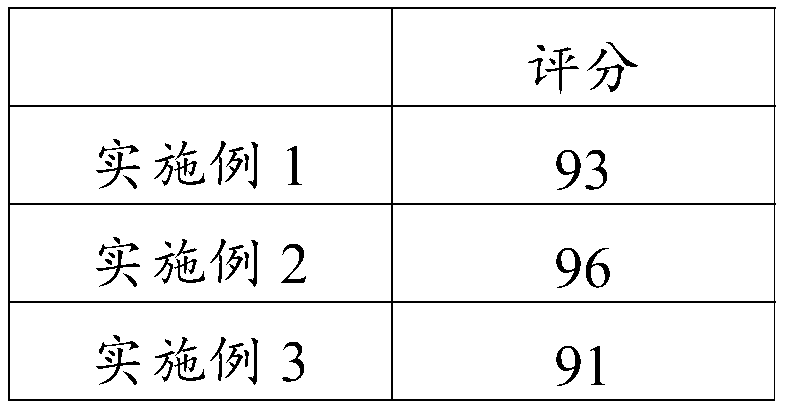

Embodiment 1

[0052] Remove fascia from beef, cut into ground beef cubes, set aside.

[0053] Weigh 0.3g Chinese prickly ash, 15g black pepper, 8g clove, 1.2g pepper, 4g cinnamon, 12g tangerine peel, 11g water chestnut shell and 9g gorgon shell, add 421.2g distilled water, after boiling, keep a low heat for 20min, filter to get Filtrate A and filter residue; add 351g of distilled water to the filter residue, after boiling, simmer for 20 minutes on low heat, filter to obtain filtrate B; mix filtrate A and filtrate B, filter under reduced pressure, at 60°C, rotary evaporate, and concentrate to obtain the compound extraction Liquid 70.2ml.

[0054] Take 1000g of the above-mentioned minced beef, 620g of compound extract, 10g of edible salt, and 44g of cooking wine. After mixing, vacuum tumble and knead at 0°C, -0.05MPa, and 5r / min for 40min. Then, wrap it tightly with plastic wrap, put it into a mold, and let it stand for 2 hours at a temperature of 0-4°C to obtain conditioned beef.

[0055] ...

Embodiment 2

[0057] Remove fascia from beef, cut into ground beef cubes, set aside.

[0058] Weigh 0.9g Chinese prickly ash, 17g black pepper, 6g cloves, 1g pepper, 3g cinnamon, 10g tangerine peel, 11.2g water chestnut shell and 8g gorgon shell, add 521.6g distilled water, after boiling, keep a low heat for 21 minutes, and filter to get Filtrate A and filter residue; add 260.8g distilled water to the filter residue, after boiling, simmer for 22 minutes on low heat, filter to obtain filtrate B; mix filtrate A and filtrate B, filter under reduced pressure, at 70°C, rotary evaporate, concentrate to obtain compound Extract 71.7ml.

[0059] Take 1000g of the above-mentioned minced beef, 700g of compound extract, 12g of edible salt, and 45g of cooking wine. After mixing, vacuum tumble and knead at 4°C, -0.08MPa, and 2r / min for 60min. Then, wrap it tightly with plastic wrap, put it into a mold, and let it stand for 2.1 hours at a temperature of 0-4°C to obtain conditioned beef.

[0060] The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com