Dust removal device with mobile cycle treatment function for building material workshop

A technology of circulating treatment and dust removal device, applied in the direction of removing smoke and dust, cleaning methods and utensils, using liquid separating agent, etc., can solve the problems of fixed dust removal area, limited dust removal area, poor dust removal effect, etc., to improve efficiency and good dust removal effect. , easy to use and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

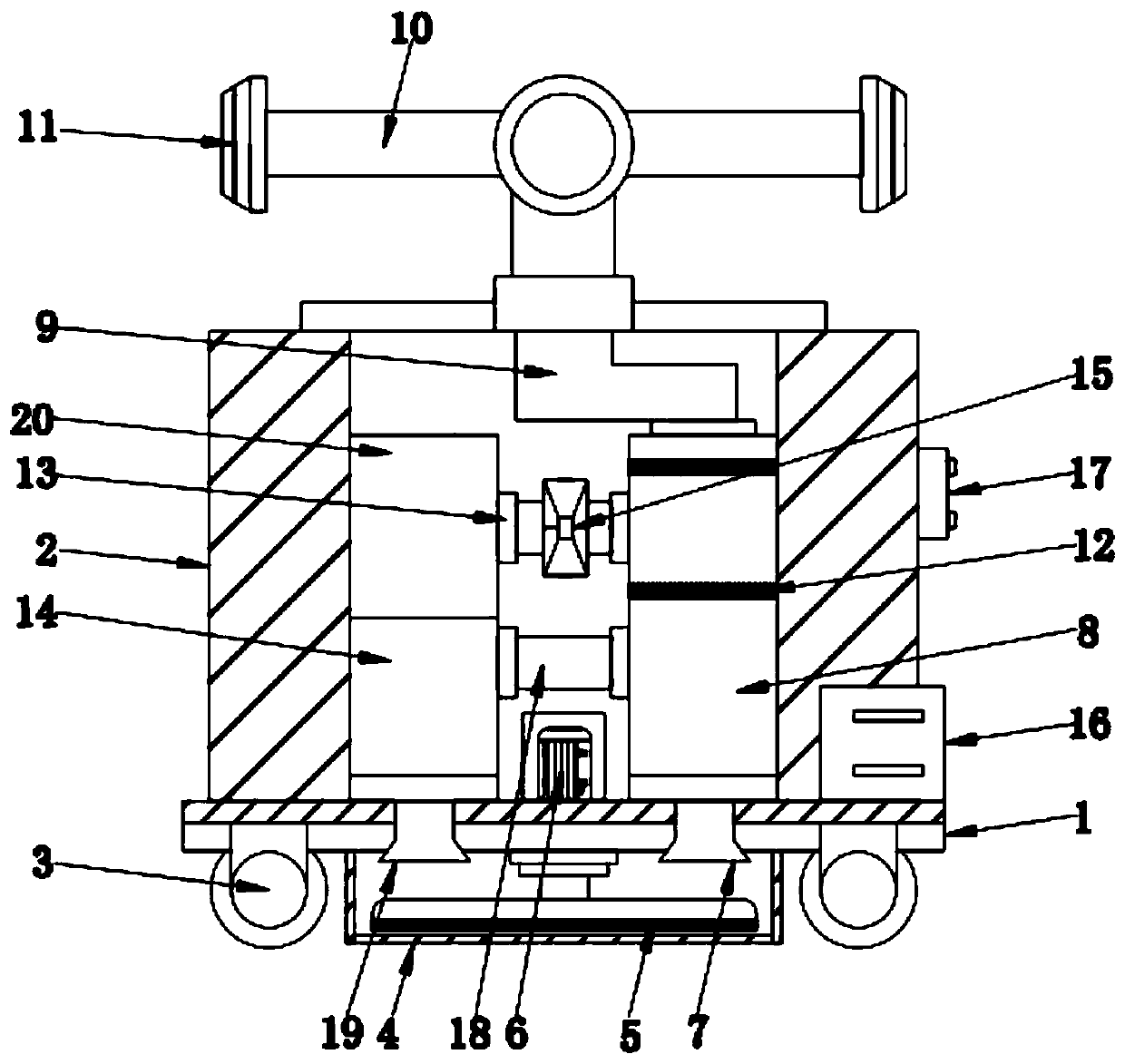

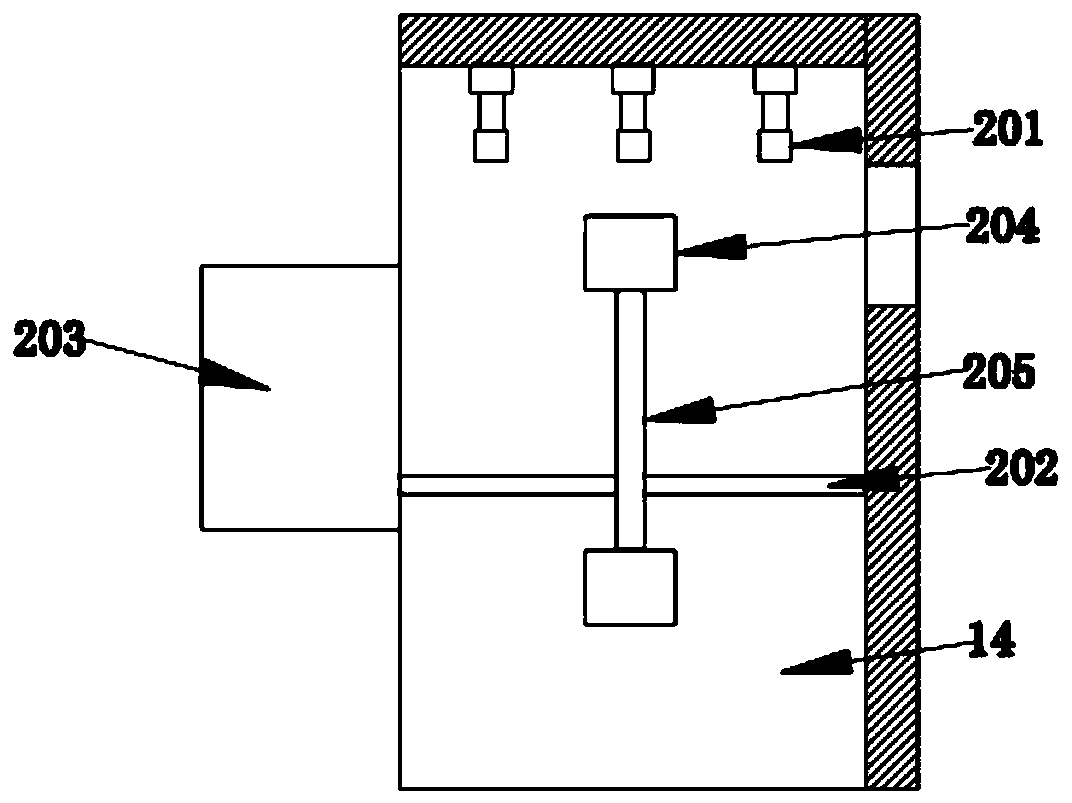

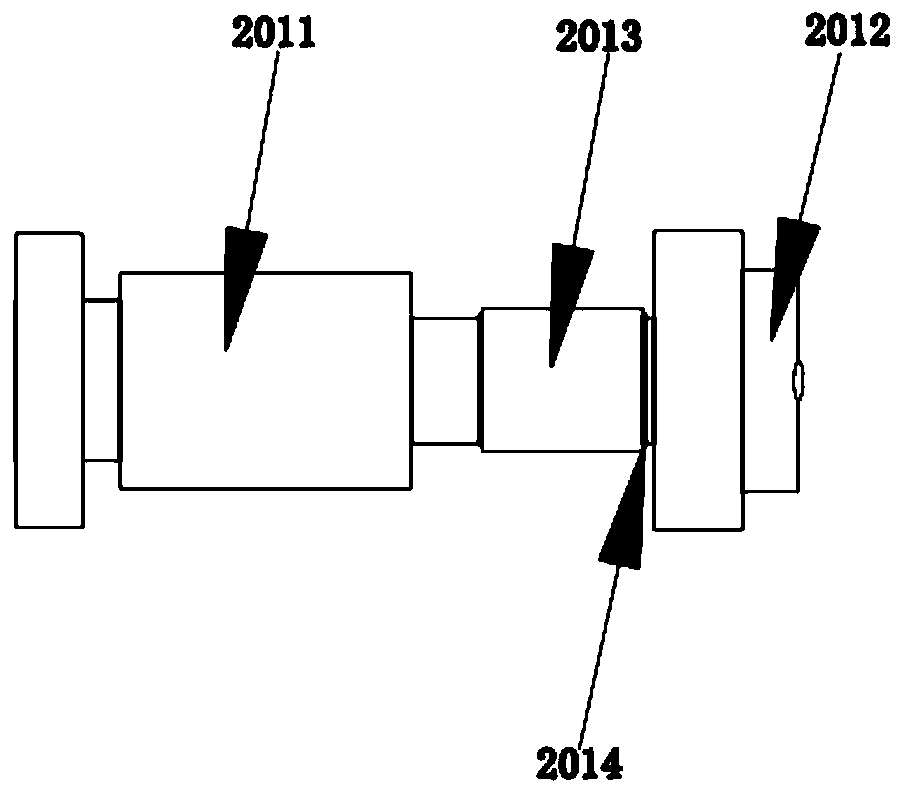

[0025] Embodiment: The present invention moves along the bottom surface of the building material workshop, which can be pushed artificially or pulled by a trolley to start the drive motor 6 and the circulation fan 15, and the drive motor 6 drives the cleaning disc 5 to rotate, and the evenly arranged bristles on the cleaning disc 5 rotate The dust on the ground is swept up, and at this time, the circulating fan 15 sucks the raised dust from the dust inlet cover 7, so that the gas doped with dust passes through the dust removal net 12 in the first dust removal tank 8 to filter out large particle diameters. dust, and enter the second dust tank 14 through the first dust removal pipe 13, while the dust collection cover 11 and the communication pipe 10 can suck the floating dust around the casing 2 into the Z-shaped dust pipe 9, and enter it through the dust removal net 12 In the second dust removal tank 14, the filter 203 and the nozzle group 201 work, and the water in the water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com