Polymer dispersing device

A technology of dispersing device and polymer, applied in mixers, shaking/oscillating/vibrating mixers, dissolving and other directions, can solve the problem of low dispersion of polymer supramolecular particles, uneven discharge from discharge pipes, and large changes in mixture concentration. and other problems, to achieve the effect of reducing concentration changes, uniform discharge, and improving mixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meanings as commonly understood by those skilled in the art.

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

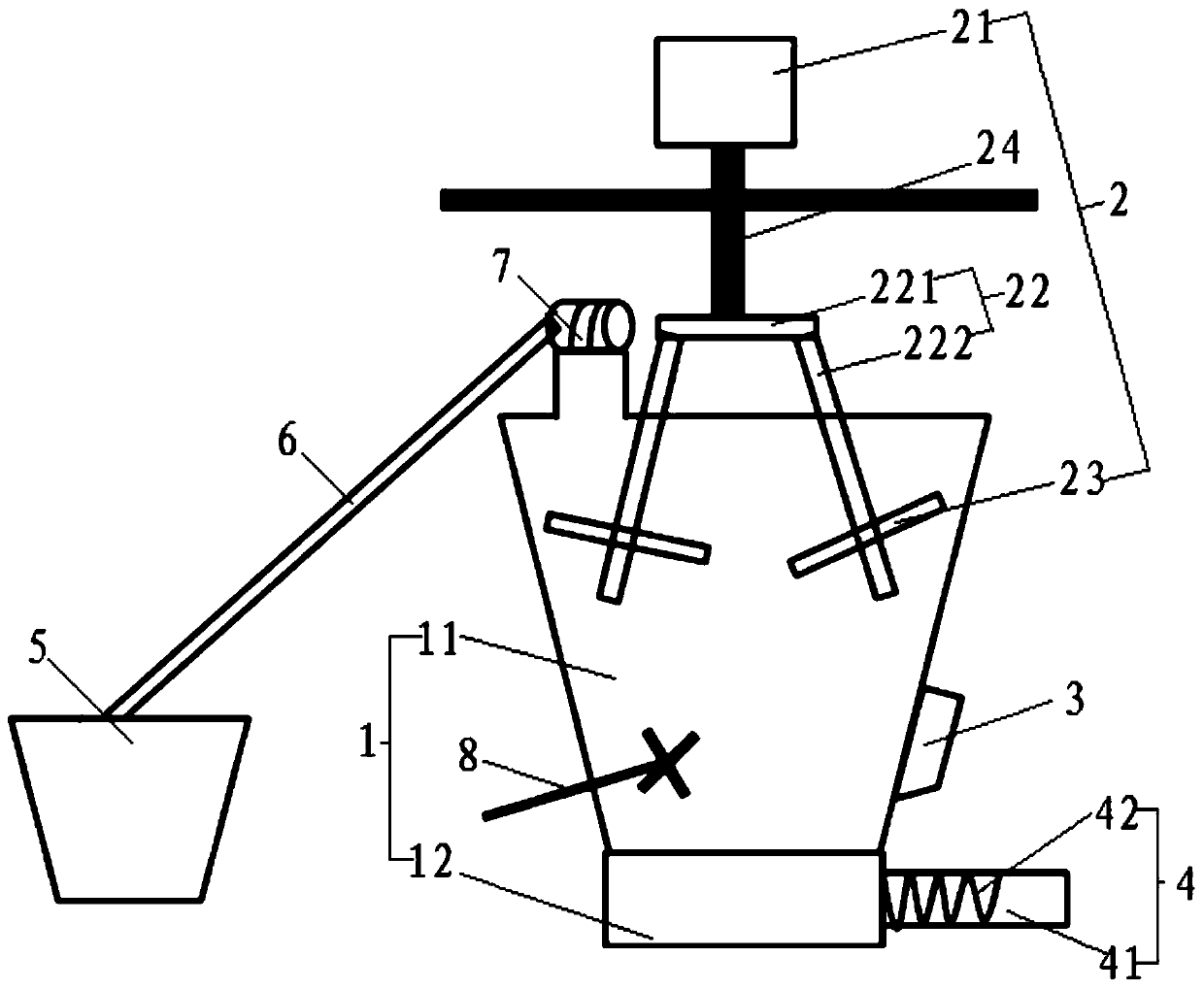

[0038] The embodiment of the present invention provides a kind of polymer dispersing device, as attached figure 1 As shown, the device includes: a storage bin 1 , a stirring mechanism 2 , an oscillator 3 and a discharging mechanism 4 .

[0039] The top of the storage bin 1 has a feed through hole.

[0040] The oscillator 3 is located on the outer wall of the storage bin 1 .

[0041] The discharge mechanism 4 communicates with the bottom end of the storage bin 1 .

[0042] The stirring mechanism 2 includes: a stirring motor 21, a stirring member 22 and a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com