Surface layer sampling device for uniformly scraping coating layer on surface of light industrial product

A light industrial product and surface coating technology, applied in the direction of sampling devices, etc., can solve the problems of inability to scrape off the coating, low work efficiency, inhalation of powder operators, etc., to achieve fast and safe scraping of the coating and improve work efficiency , the effect of less error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

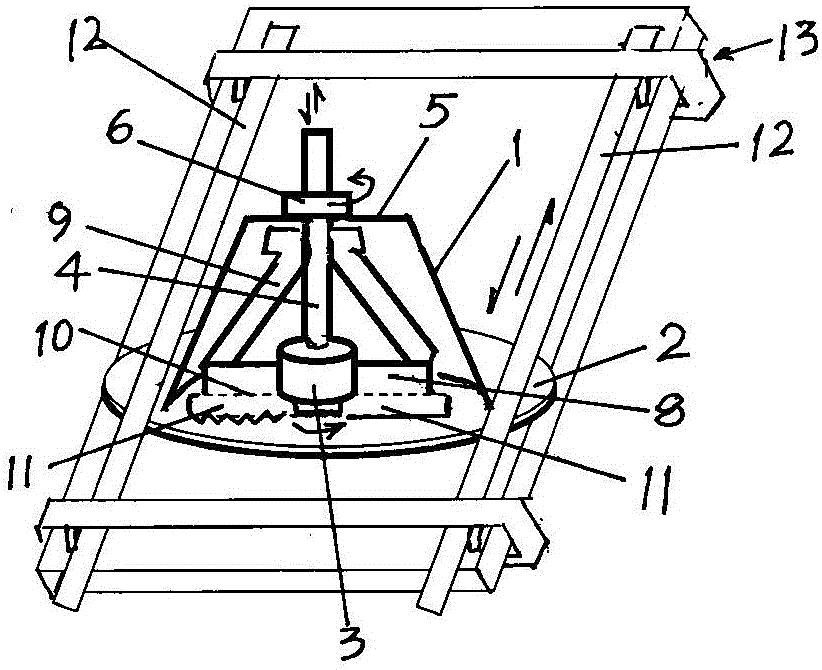

[0021] Example 1, a blade-type surface sampling device that evenly scrapes off the surface coating of light industrial products

[0022] Such as figure 1 , including a cylinder 1 with an opening downward, an annular ring 2 is provided on the opening edge of the cylinder 1, a motor 3 is arranged in the cylinder 1, a support shaft 4 is connected to the housing of the motor 3, and the other support shaft 4 One end protrudes from the hole on the top cover 5 of the cylinder body 1, and part of the support shaft 4 extending out of the top cover 5 of the cylinder body 1 is threaded, and the threaded support shaft 4 part is covered with a nut 6; the nut 6 and the cylinder The outer surface of the top cover 5 of the body 1 is provided with digital scales; or the 4 parts of the threaded support shaft are provided with digital scales;

[0023] The rotating shaft of the motor 3 is provided with a plurality of blades 7 that rotate with the motor, the blades of the blades 7 are downward, a...

Embodiment 2

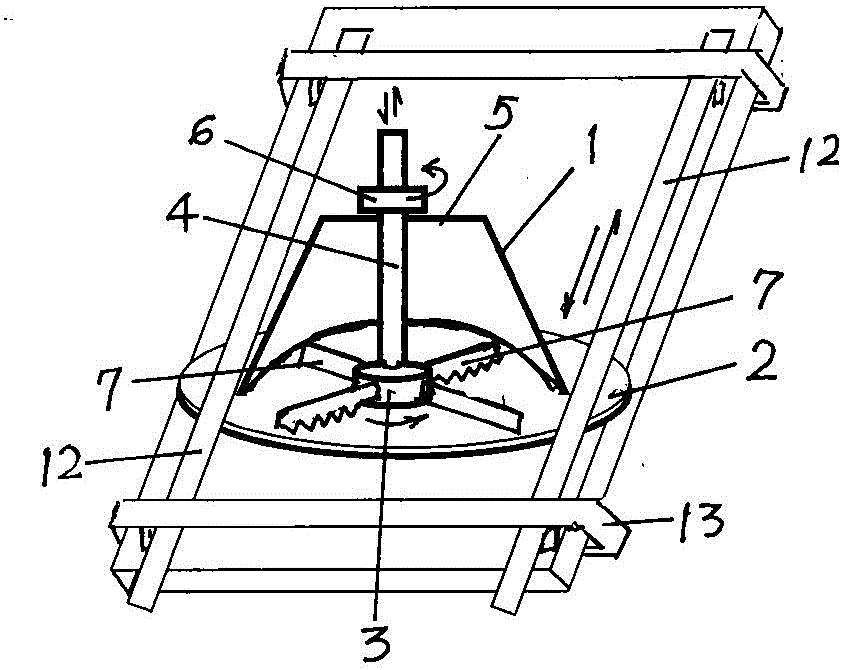

[0026] Example 2, a blade-type surface sampling device that evenly scrapes off the surface coating of light industrial products

[0027] Such as figure 2 , including a cylinder 1 with an opening downward, an annular ring 2 is provided on the opening edge of the cylinder 1, a motor 3 is arranged in the cylinder 1, a support shaft 4 is connected to the housing of the motor 3, and the other support shaft 4 One end protrudes from the hole on the top cover 5 of the cylinder body 1, and part of the support shaft 4 extending out of the top cover 5 of the cylinder body 1 is threaded, and the threaded support shaft 4 part is covered with a nut 6; the nut 6 and the cylinder The outer surface of the top cover 5 of the body 1 is provided with digital scales; or the 4 parts of the threaded support shaft are provided with digital scales;

[0028] The rotating shaft of the motor 3 is provided with a rotating disk 8 that rotates with the motor, and the top of the rotating disk 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com