A rapid punching device for auto parts

A technology for auto parts and punching devices, which is applied in the field of machining equipment and stamping equipment, and can solve problems such as slow punching speed, non-continuous operation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

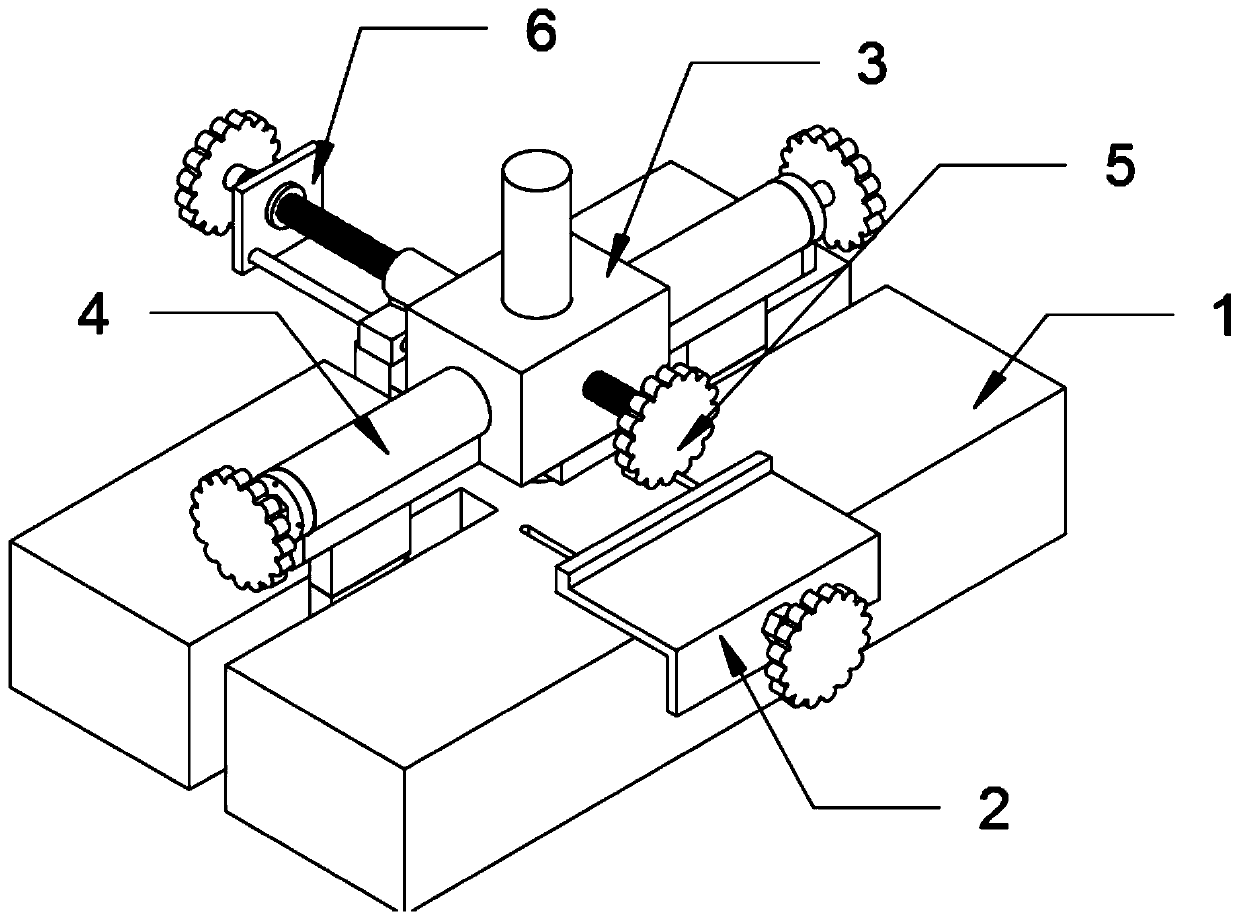

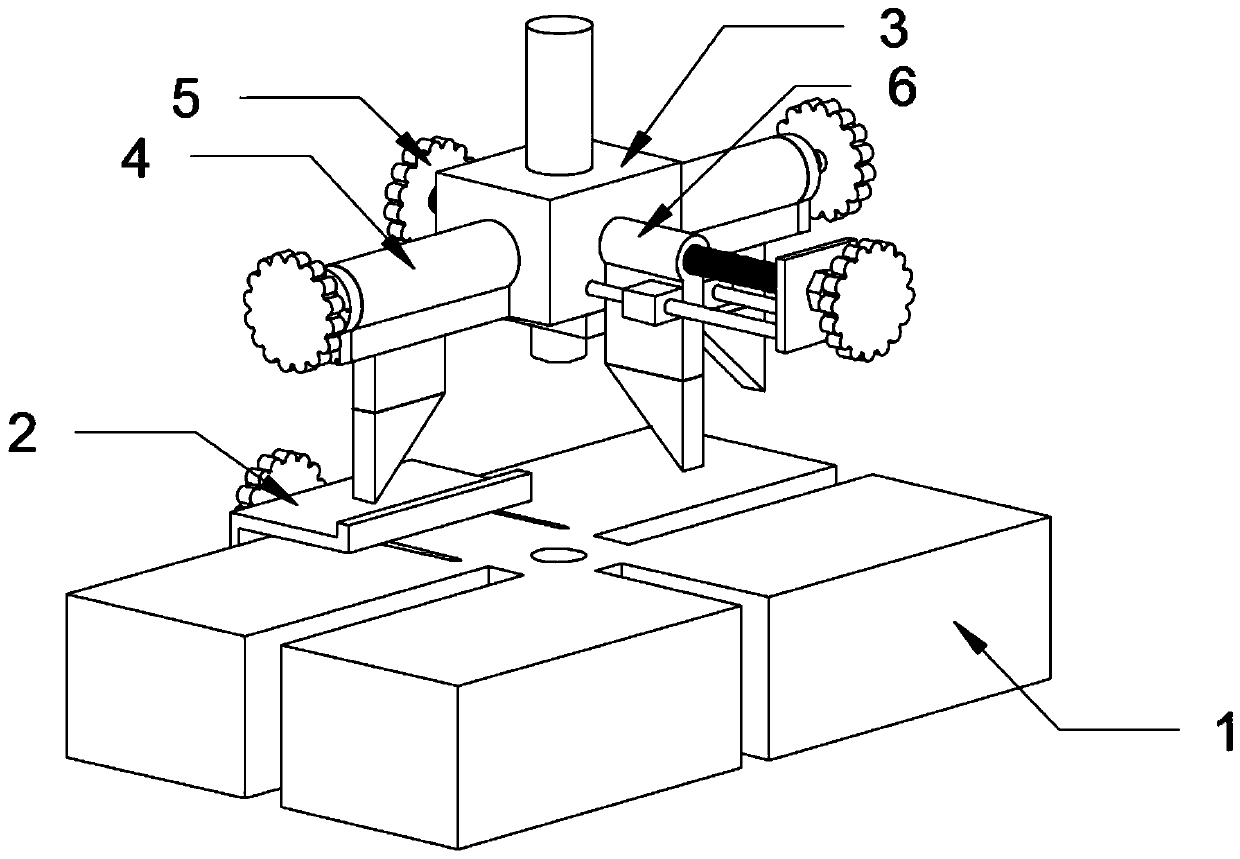

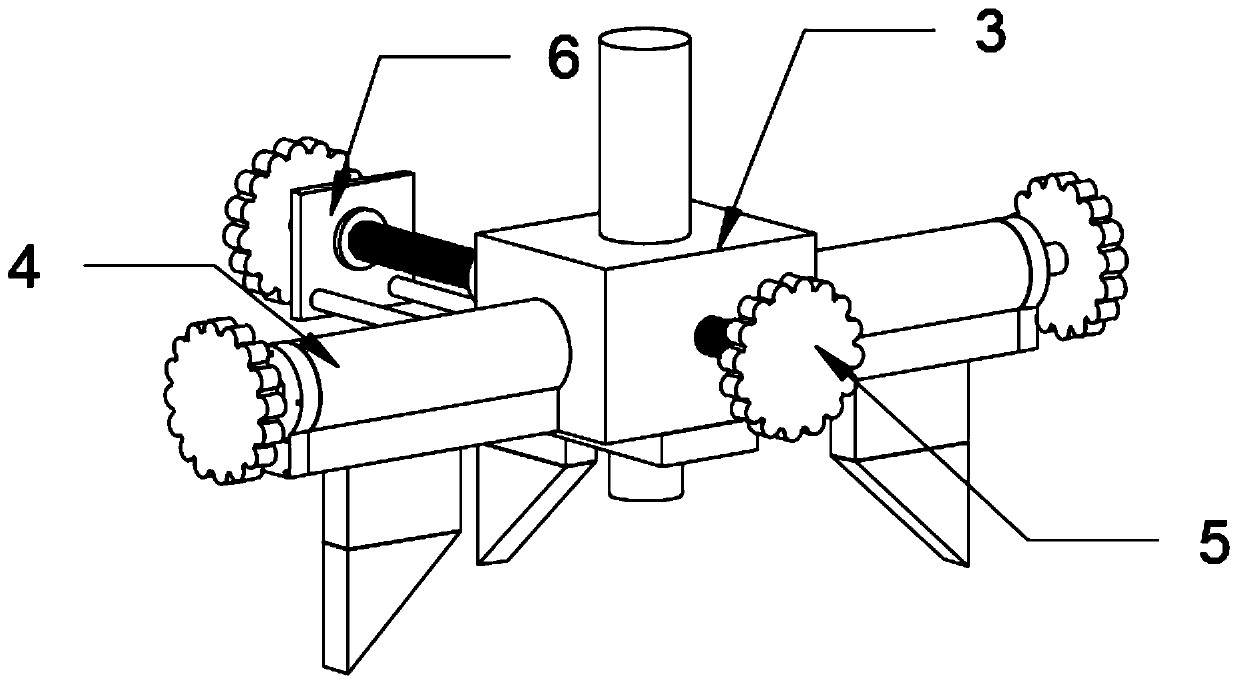

[0036] as attached figure 1 To attach Figure 8 Shown:

[0037]The present invention provides a quick punching device for auto parts, including: a base plate 1, a sliding track 101, a rectangular slot A102, a rectangular slot B103, a limit baffle structure 2, a baffle main body 201, a sliding column 202, and an adjustment stud A203, bearing iron 3, horizontal fixing structure 4, sleeve rod 401, limit cover plate 402, cylindrical iron 403, stud A404, stud B405, horizontal fixing plate 406, first horizontal fixing plate 40601, second horizontal fixing plate 40602, fixing bolt 5, longitudinal fixing structure 6, longitudinal fixing plate 601, first longitudinal fixing plate 60101, second longitudinal fixing plate 60102, cylindrical rod 602, rectangular plate 603, stud C604 and nut 01; bottom plate 1 top surface rear A sliding track 101 is provided at the side position, and a rectangular groove A102 is provided at the middle position of the left end surface and the right end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com