Lightweight beam of numerical control laser cutting machine

A numerical control laser and cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low cutting accuracy and cutting efficiency of laser cutting machines, affecting the overall performance of laser cutting machines, insufficient dynamic performance, etc. , to achieve the effect of light weight, simple structure and sufficient dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

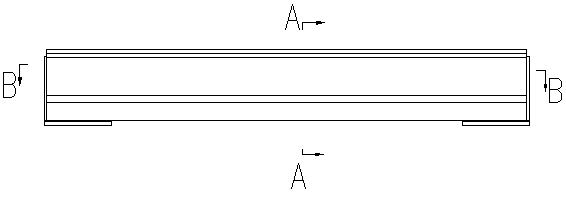

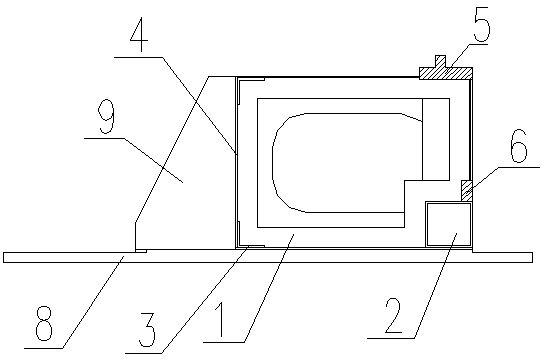

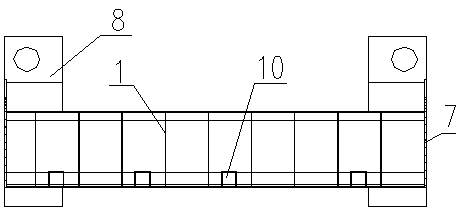

[0017] A light-weight beam of a numerically controlled laser cutting machine, comprising a beam main body, the beam main body comprising several parallel ribbed panels 1, the front lower corners of which are connected by square tubes 2, and several curved rib panels The upper front corner of the front side and the upper and lower corners of the rear side of 1 are covered with angle steel 3, and the angle steel 3 and the square tube 2 are covered with a protective plate 4. The upper end of the beam main body is provided with an upper guide rail mounting plate 5 on the front side, and the front end of the beam main body The lower guide rail mounting plate 6 is arranged on the surface, and the end plates 7 are respectively provided at both ends of the main body of the beam.

[0018] As a further improvement of the above technical solution, reinforcing ribs 9 are respectively provided at both ends of the rear side of the beam main body, and the reinforcing ribs 9 are connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com