Plug piece part forming method

A technology of parts and plugs, which is applied in the field of forming parts of plugs, can solve the problems of low material utilization rate, many processes, and inability to bend sideways.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, with reference to the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of a method for forming plug blade parts according to the present invention will be described in detail as follows.

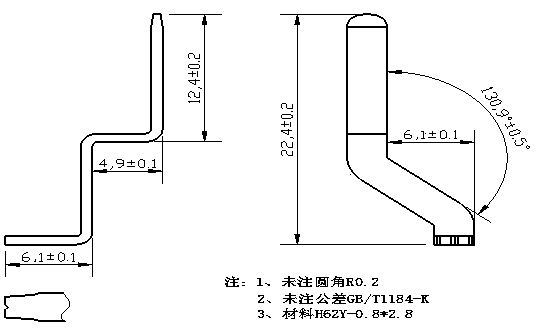

[0034] see Figure 2-4 , a method for forming plug piece parts, characterized in that the plug piece is processed by a servo spring machine, the flat material of 2.8×0.8 passes through the feeder, enters the servo spring machine through the correction wheel, and passes through the servo spring machine for six processes. The servo motor at one station, the free hand at another station and various tools perform multiple bending and cutting processes on the parts to achieve the desired part size;

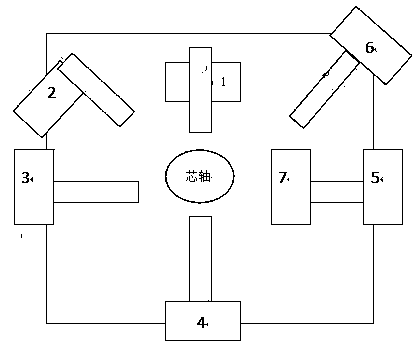

[0035] The specific processing system includes a feeding system, a bending system and a control system. There are seven stations in the bending system, station A1, station B2, station C3, station D4, station E5, sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com