Experimental device for testing key component of rotary side wall coring instrument

A technology for component testing and experimental devices, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of high cost, unstable performance, low reliability, etc., to eliminate the risk of construction , The effect of speeding up the development cycle and reducing the test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

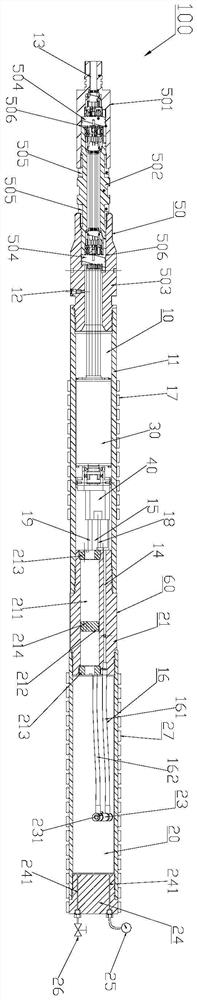

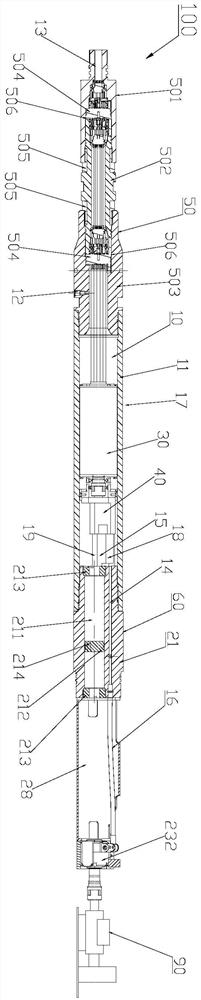

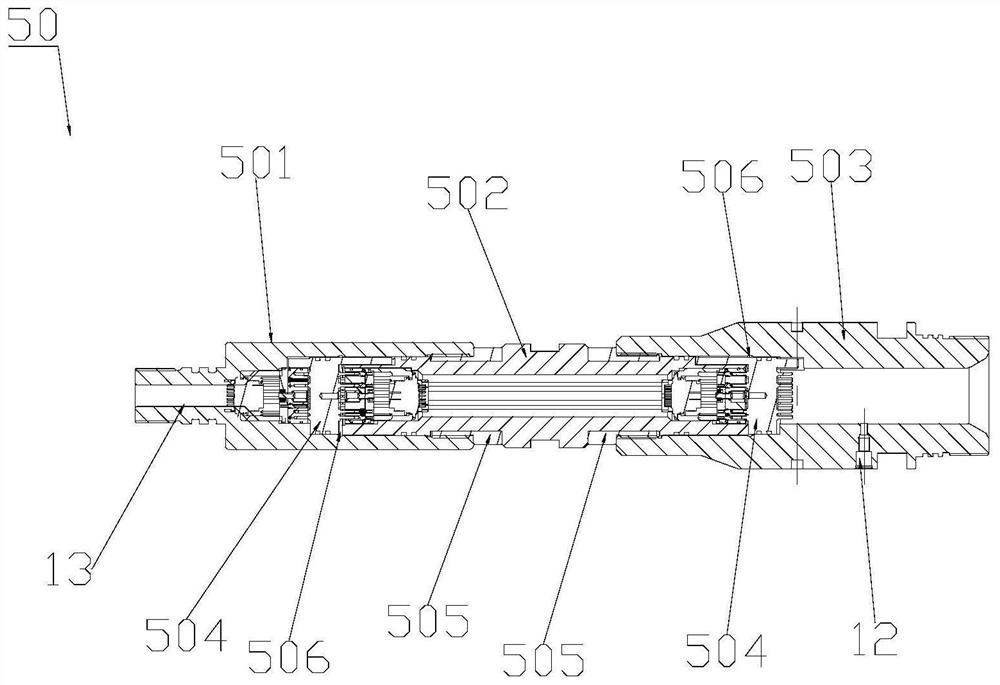

[0021] To better understand the object of the present invention, structure and function, in conjunction with the following drawings, the present invention is a rotary wall member taken favorite key test described in further detail by the experimental apparatus.

[0022] Figure 1 to 3 Shows a schematic structure of a key member experimental test different embodiments according to the rotation of the wall taken favorite embodiment of the present invention. Combine figure 1 with Figure 5 Shown, an embodiment of a rotary member from sidewall favorite key experimental test apparatus 100 includes a first sealed chamber 10, a first sealed chamber 10 of the present invention comprises: a first chamber housing 11, a first a chamber within the housing 11 is provided with the motor 30 and the hydraulic pump 40 is connected to the motor 30; 50, 50 external sealing external joint assembly joint assembly connected to the left end of the first housing chamber 11 is formed on the joint assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com