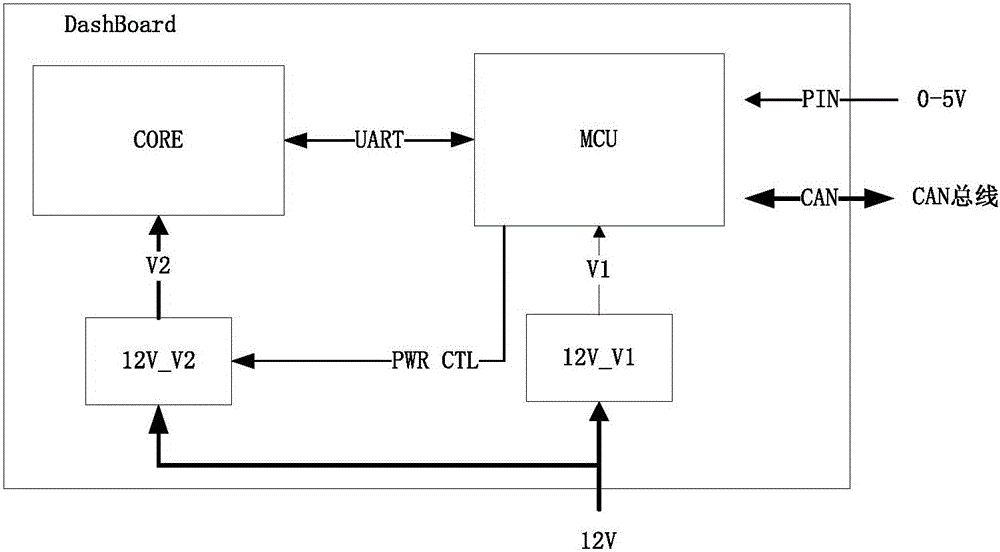

System architecture of all-liquid crystal automobile instrument

A technology of automotive instrumentation and system architecture, applied in the field of automotive instrumentation, can solve problems such as poor reusability, difficulty in platform replacement, and unsightly instrument development interface, and achieve the effects of speeding up the development cycle, saving development costs and development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

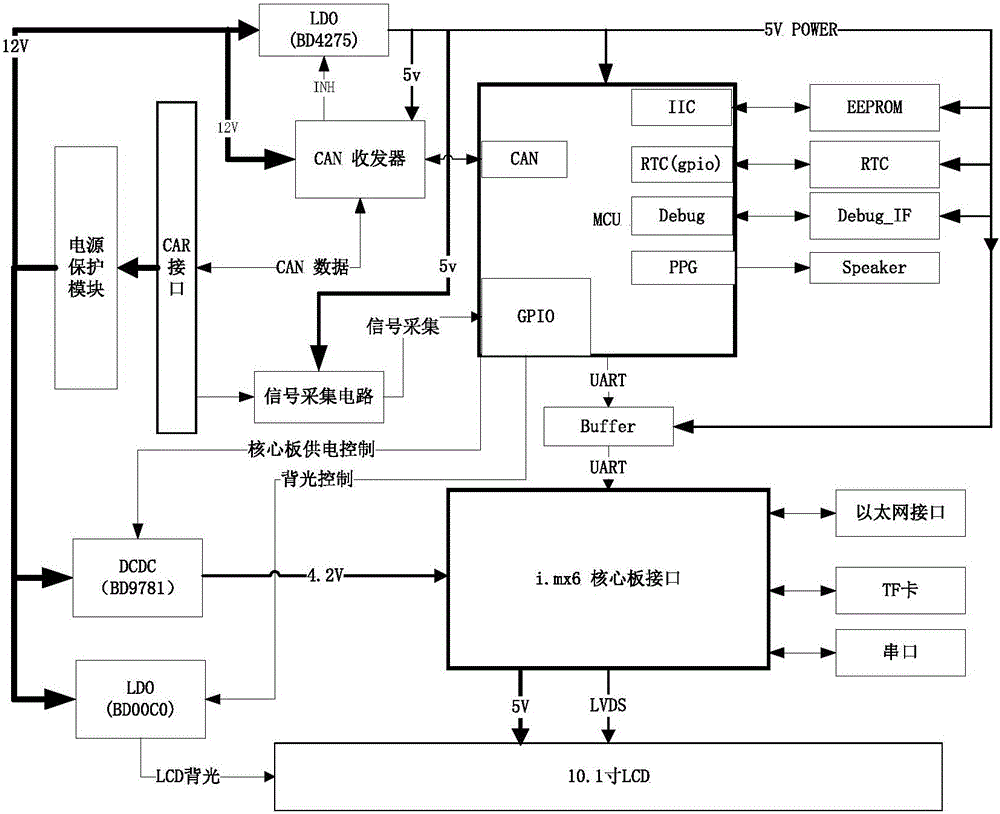

[0024] like figure 2 As shown, in the system architecture of the full LCD car instrument in this embodiment, the core processor adopts IMX6, the power supply voltage adopts 4.2V, the controller adopts Fujitsu MB91F522, and the power supply voltage is 5V. The power chip 12V_V1 is BD4275 and 12V_V2 is BD9781.

[0025] IMAX6 is equipped with Ethernet interface, TF card, serial port, and is connected with 10.1-inch LCD screen.

[0026] The whole system adopts 12V power supply, 12V voltage is converted to 5V voltage through LDO (low dropout regulator) low dropout linear regulator, and 5V power supply is used for CAN transceiver, MCU, EEPROM, RTC clock, debug interface, buffer, and signal acquisition circuit powered. The 12V voltage is converted into 4.2V voltage by DC-DC (direct current to direct current conversion) to supply power for IMX6. The 12V voltage passes through the LDO (Low Dropout Linear Regulator) to provide backlight power for the 10.1-inch LCD screen, and the pow...

Embodiment 2

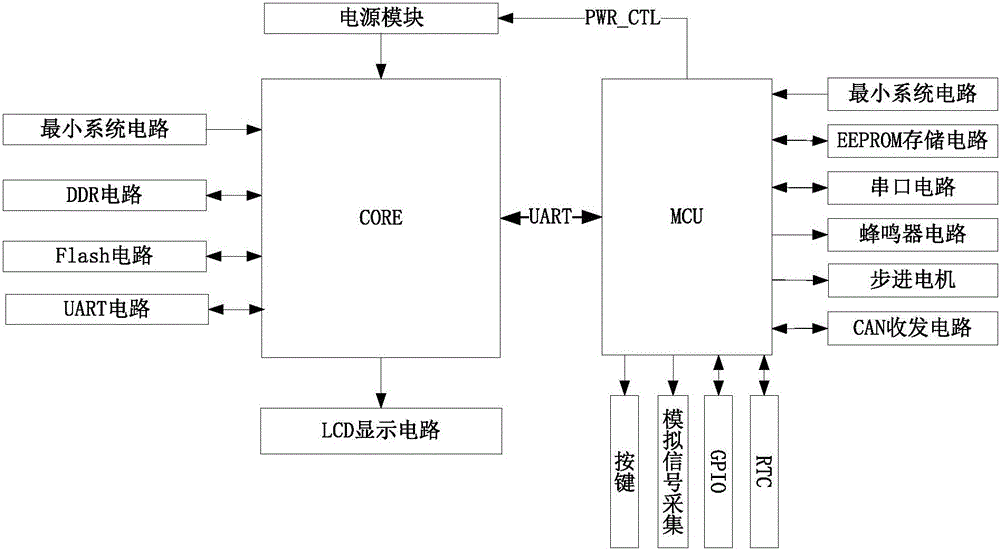

[0031] like image 3 As shown, it is a system block diagram of a combination car instrument, which uses a 7-inch LCD and a stepper motor. The MCU adopts Fujitsu MB96F385, and the CORE adopts Fujitsu MB86R01 (maximum support 1024*768 resolution). The serial port is used for communication between MCU and CORE. The MCU peripheral circuit mainly includes the minimum system circuit (including crystal oscillator circuit, reset circuit, download / debugging circuit), EEPROM circuit (saving mileage, fault code and customer configuration information), serial port circuit (for debugging output and communicating with CORE), Buzzer circuit, stepper motor (for vehicle speed indication), CAN transceiver circuit, RTC (real time clock), GPIO, analog signal acquisition (AD acquisition), buttons (for interface switching, mileage reset), etc. CORE peripheral circuits mainly include the minimum system circuit, DDR circuit, FLASH circuit, UART circuit and LCD display circuit. The power control of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com