Optimal torque distribution method based on distributed electric drive vehicle

A technology of optimal torque and distribution method, applied in electric vehicles, control drives, vehicle components, etc., can solve problems such as prolonging simulation time, increasing calculation burden, and requiring high objective function gradient and Hessian matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment takes the driving demand torque of distributed electric drive vehicles as the distribution object, implements it on the premise of the technical solution of the present invention, and provides detailed implementation methods. The scope of protection of the present invention includes but not limited to distributed electric drive vehicles .

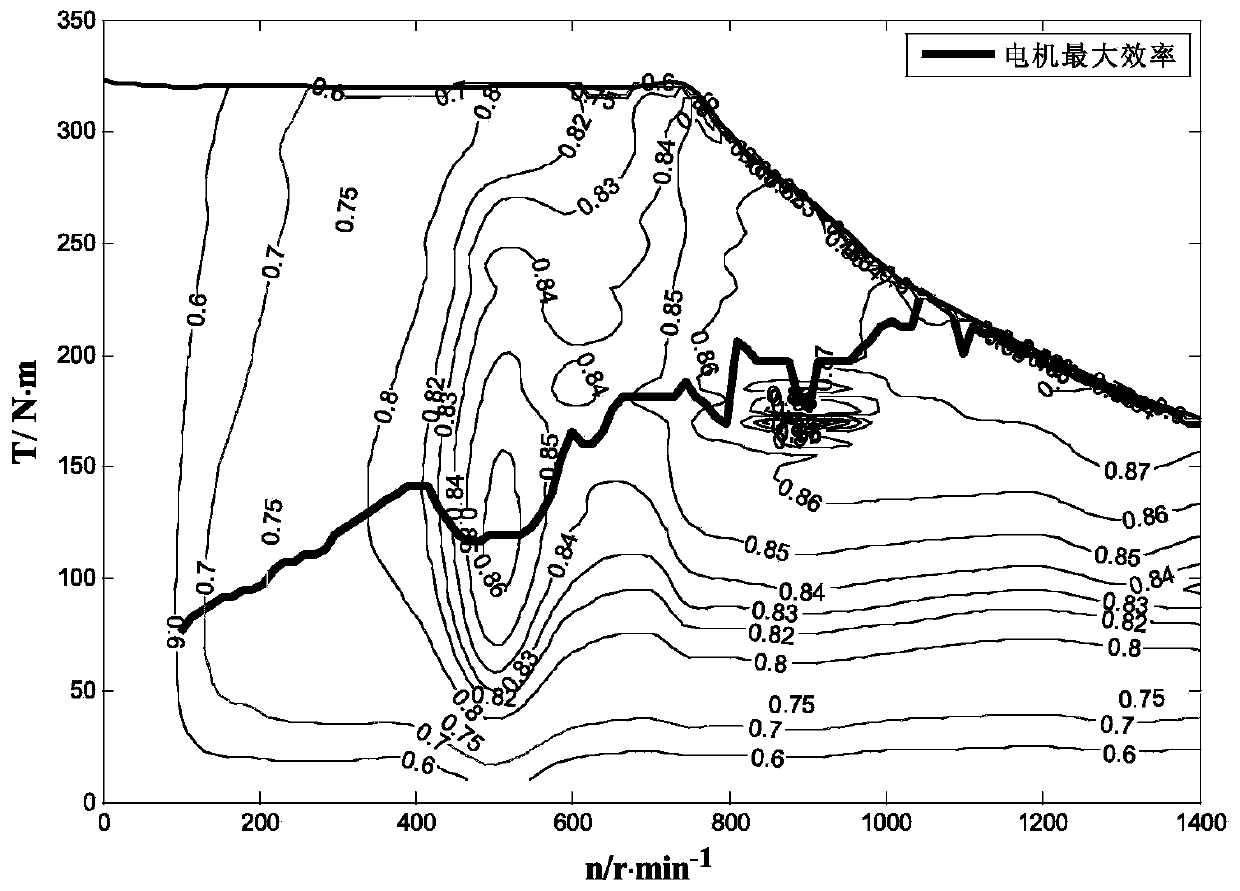

[0027] as attached figure 1 As shown, the efficiency of the drive motor is related to the required torque and the wheel speed. The red line in the figure is the maximum motor efficiency corresponding to a certain speed and the required torque. In order to improve the efficiency of the vehicle drive system, the drive motor should work as high as possible During the efficiency period, that is near the red curve.

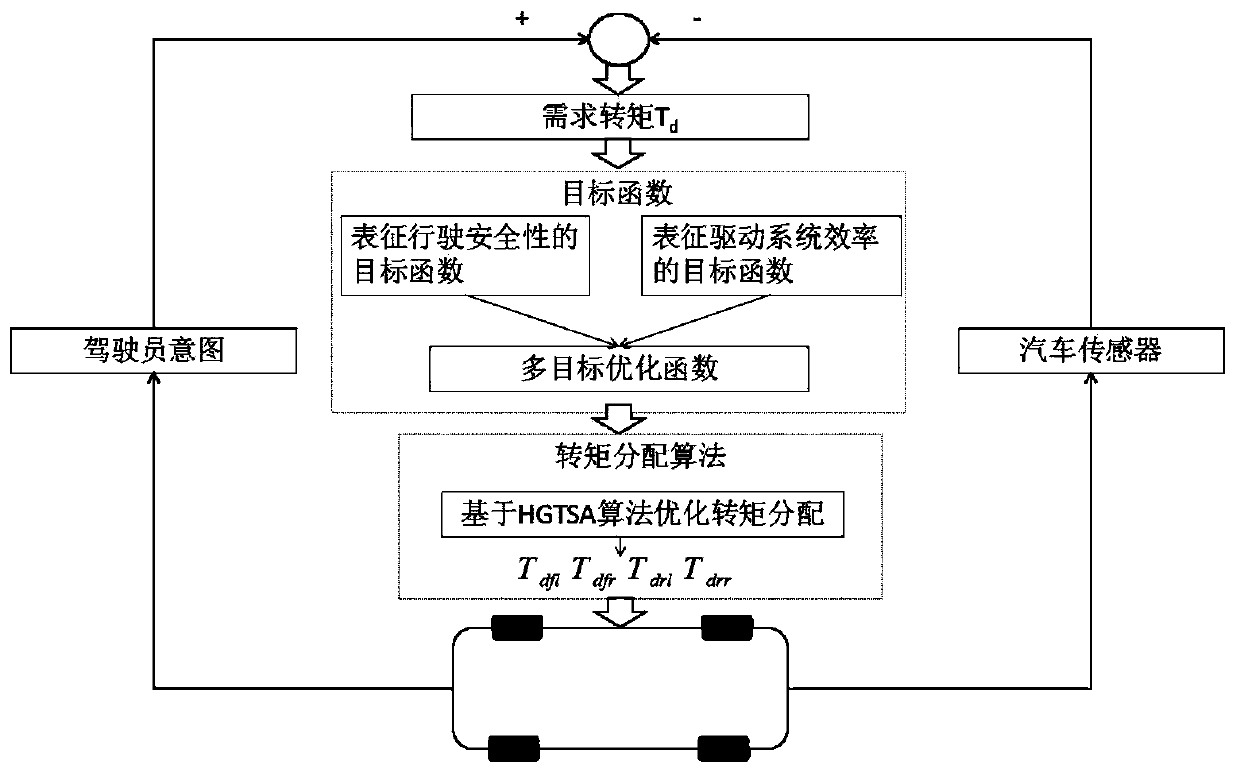

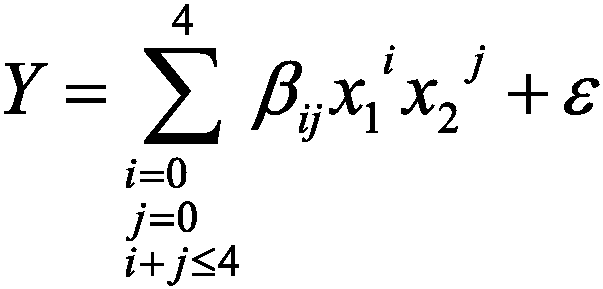

[0028] Considering that the distributed electric drive vehicle is a highly comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com