Transporting device for production line of plate beam

A transportation device and production line technology, which is applied in the field of transportation devices for plate girder production lines, can solve problems such as information transcription errors, low efficiency, and information delays, and achieve high application value, low price, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

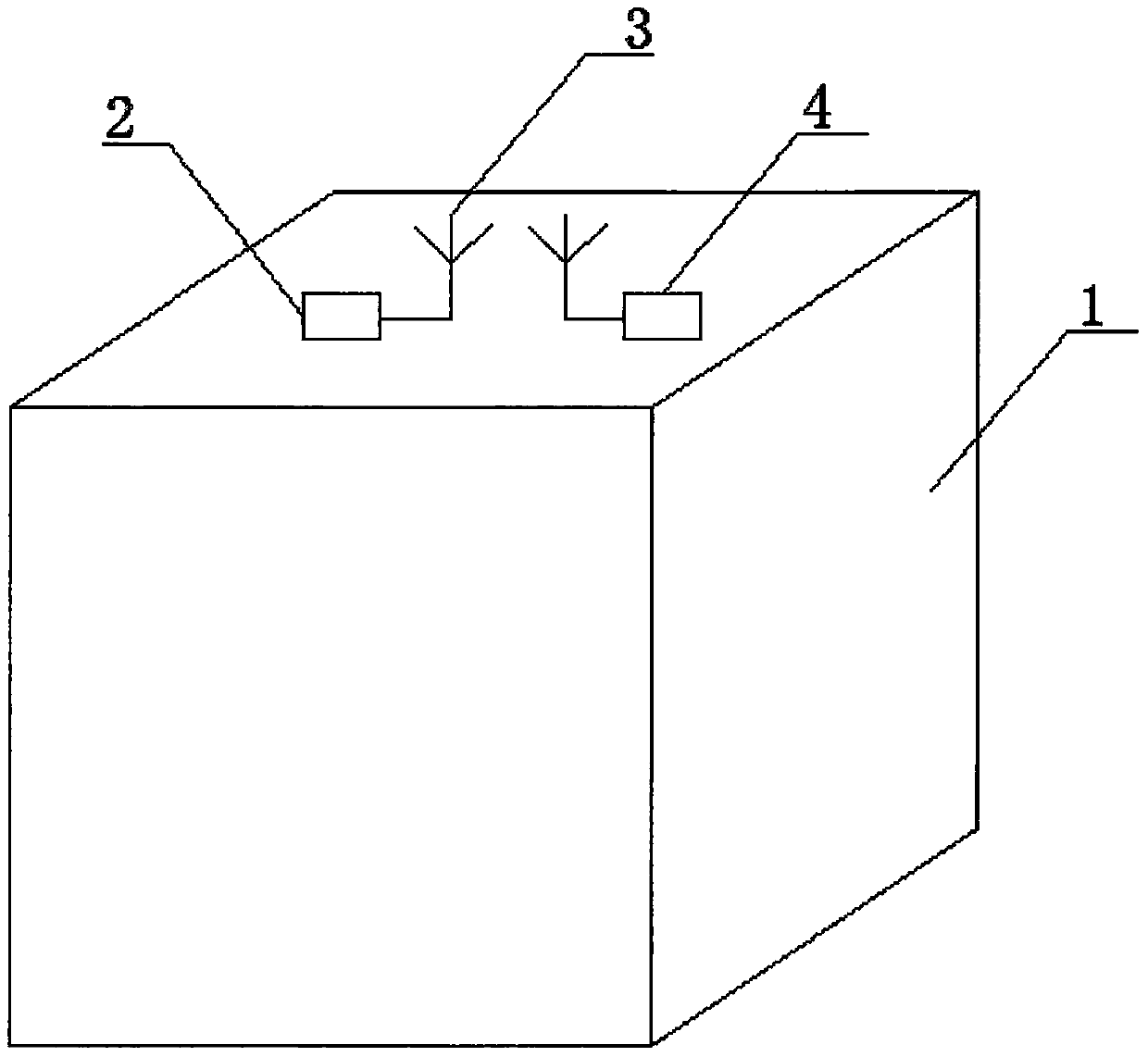

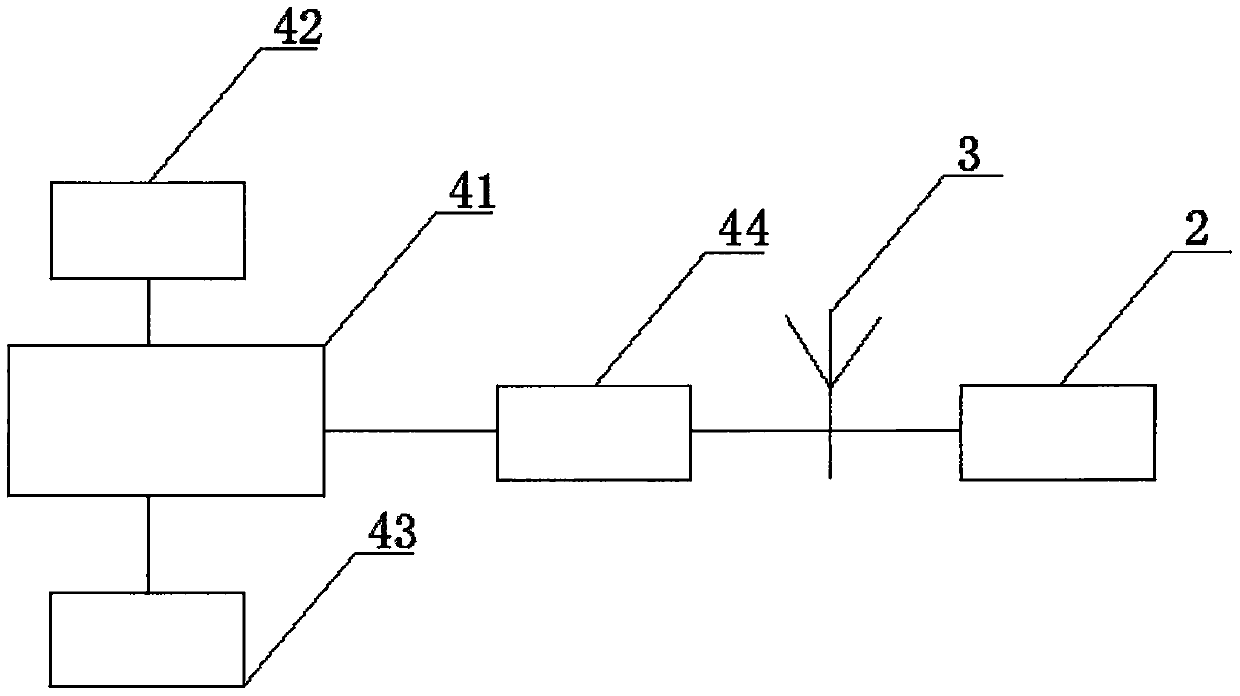

[0021] like figure 1 As shown, a transportation device for a plate girder production line includes a plate girder container body 1 on which a passive electronic tag 2, an antenna 3 and an RFID reader 4 are installed; the RFID reader 4 includes a CPU processor 41, a serial port module 42, an Ethernet module 43, and a radio frequency read-write module 44; the passive electronic tag 2 communicates with the CPU processor 41 through the antenna 3 through the radio frequency read-write module 44 connection; the serial port module 42 and the Ethernet module 43 are both electrically connected to the CPU processor 41 . Wherein, the CPU processor 41 is an LPC2119 chip, the serial port module 42 is an RS485 serial port, and the Ethernet module 43 includes a PHY chip, a network transformer chip and an RJ45 interface, and the RJ45 interface passes through the network voltage transformer successively. The chip and the PHY chip are electrically connected to the CPU processor 41 . Wherein, ...

Embodiment 2

[0023] The only difference from Embodiment 1 is that the RFID reader / writer 4 further includes a watchdog circuit, and the watchdog circuit is electrically connected to the CPU processor 4 . Wherein, the watchdog circuit is an SP706 chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com