Trolley cam friction driven whole line drive control structure

A technology of friction drive and control structure, applied in the directions of travel mechanism, transportation and packaging, load hanging components, etc., can solve the problems of assembly error of the drive sub-mechanism, difficulty in maintenance, unilateral contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

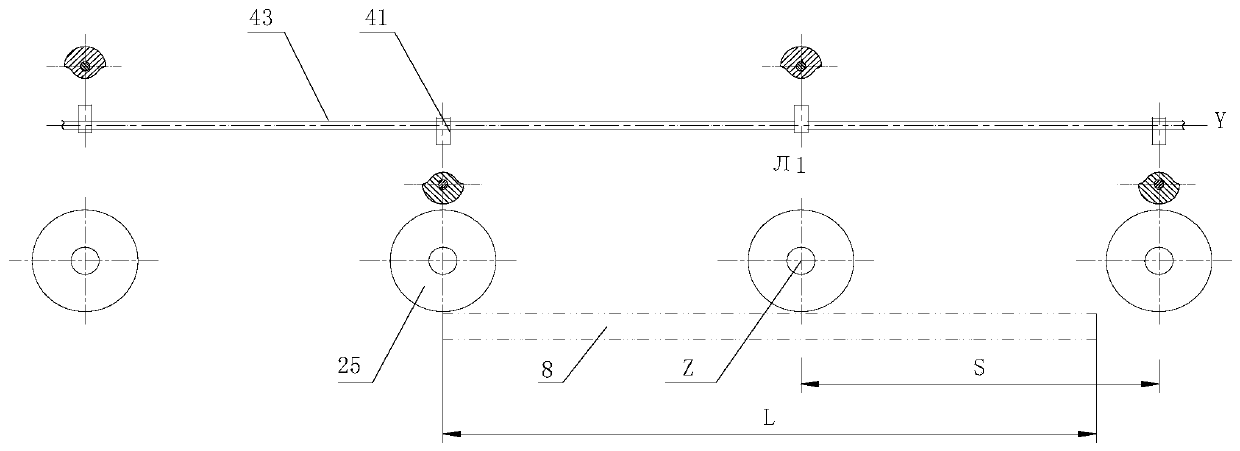

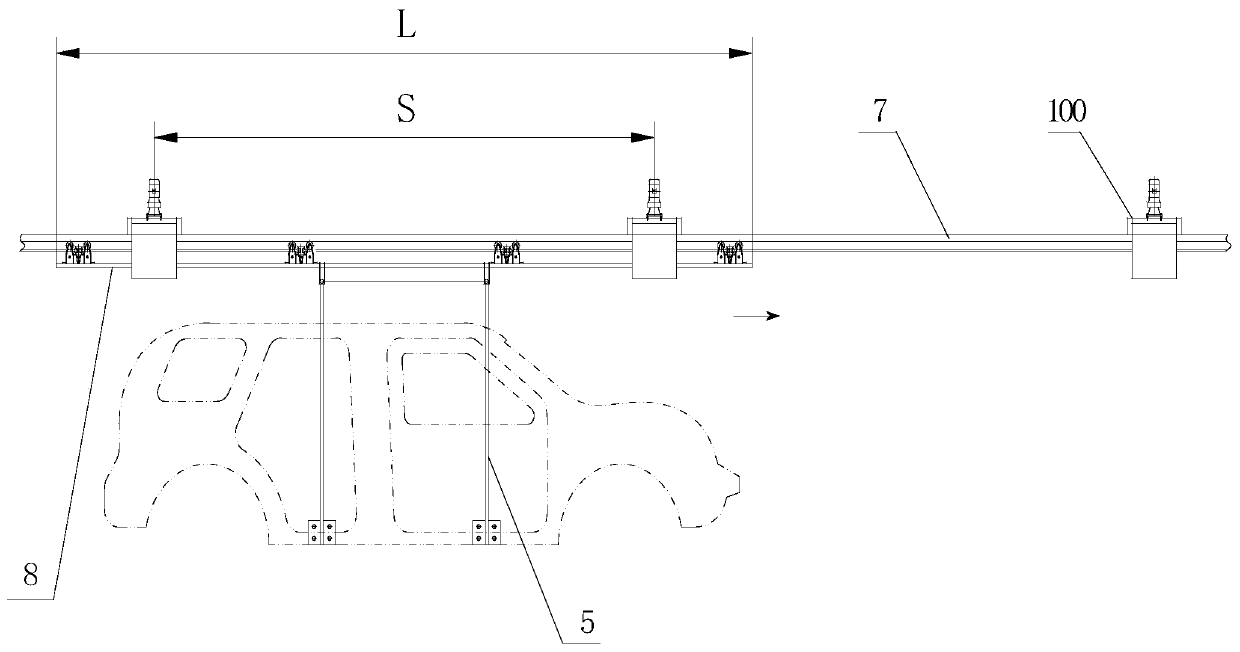

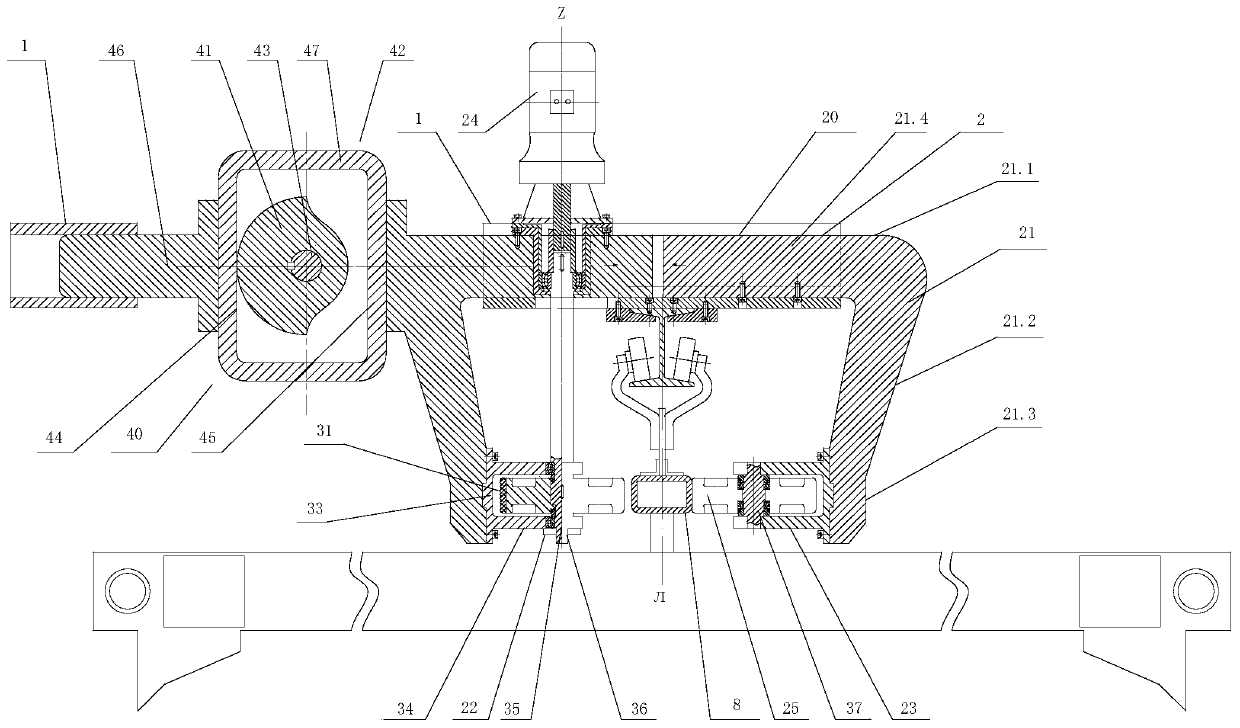

[0046] As shown in the figure, a trolley cam friction driving device 100, the trolley 5 rolls and fits on the lower beam of the I-beam 7 through the guide wheel 6, the trolley 5 includes a driving rod 8, and the driving rod 8 has a plane of symmetry L,

[0047] Including a fixed plate 1, the fixed plate 1 is horizontally fixed on the top of the upper beam of the I-beam 7; the fixed plate is provided with a guide chute 2;

[0048] The guide chute 2 is provided with a friction wheel mechanism 20, and the friction wheel mechanism 20 includes a pair of opening and closing frames 21, and at least one of the opening and closing frames 21 is slidably fitted in the guide chute 2;

[0049] The friction wheel mechanism 20 also includes a driving wheel mechanism 22 and a driven wheel mechanism 23, and the driving wheel mechanism 22 and the driven wheel mechanism 23 are respectively fixed on the opening and closing frame 21; or the friction wheel mechanism 20 also includes a pair of drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com