Embossed leather manufacturing technology and coating machine

A coating machine and spraying mechanism technology, applied in the direction of leather surface mechanical treatment, composite leather, leather surface treatment, etc., can solve the problems of easy blockage of spray paint holes, thinning of thickness, easy to reduce the uniformity of spray paint, etc. effect, improve uniformity, and improve the effect of spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

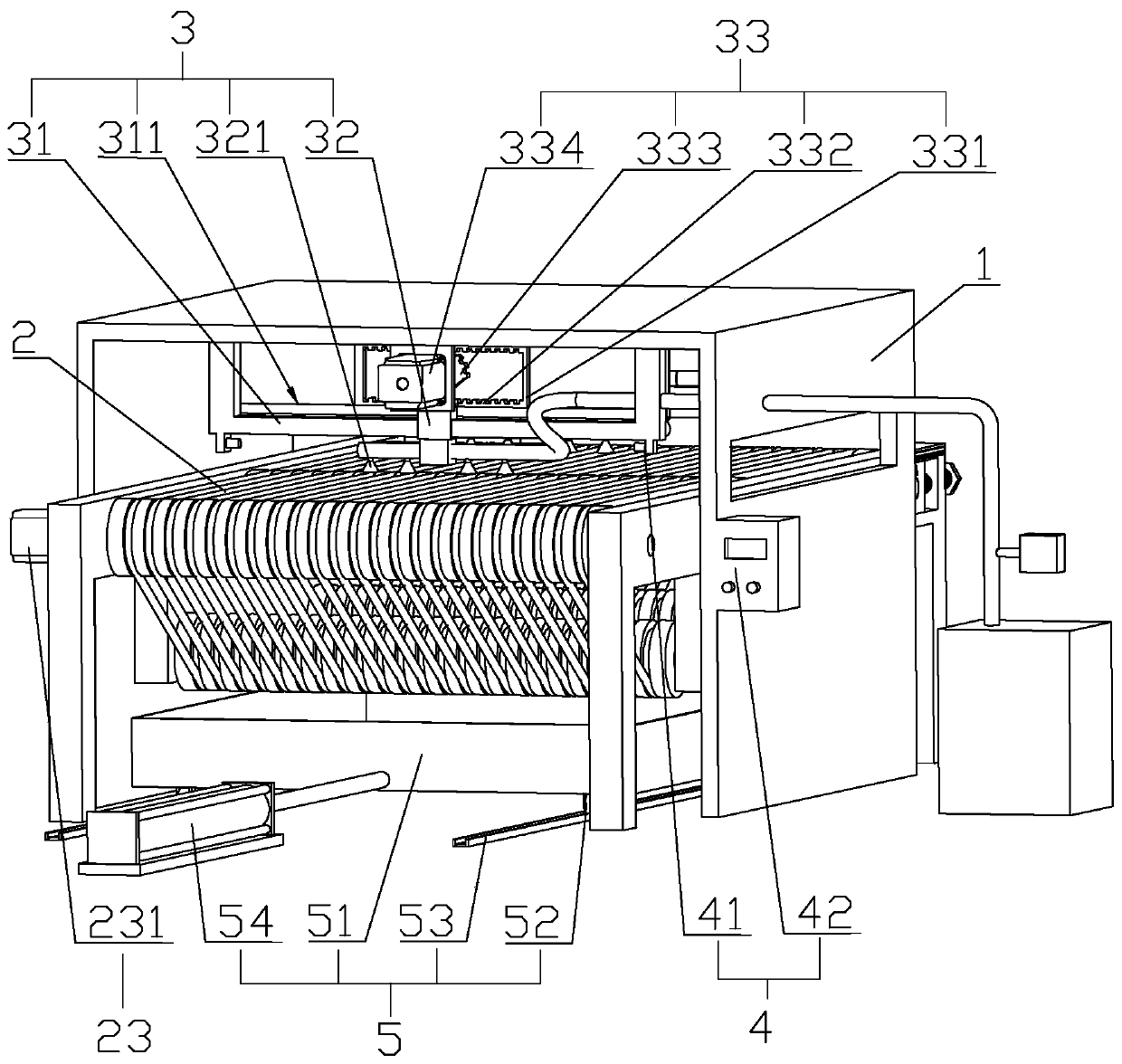

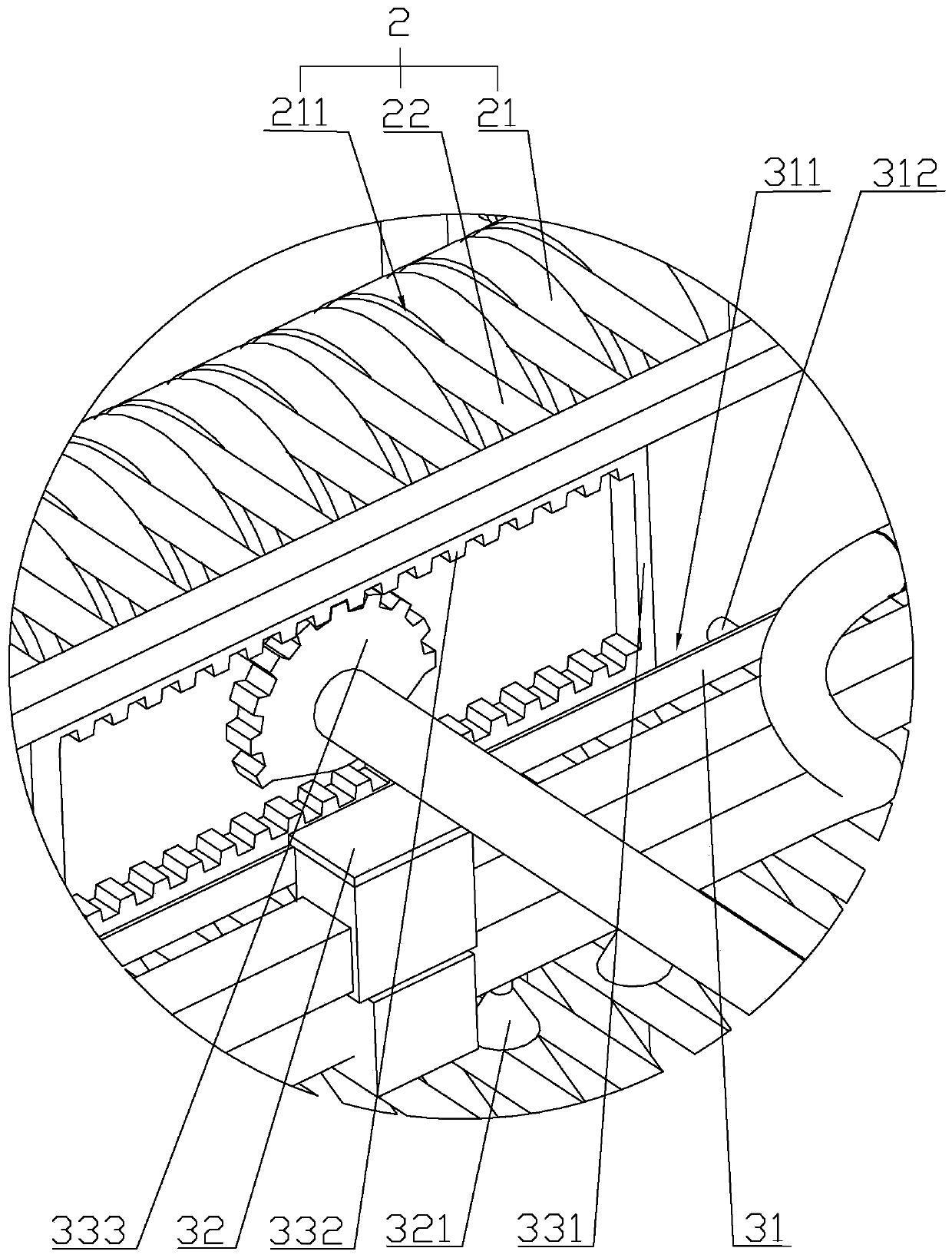

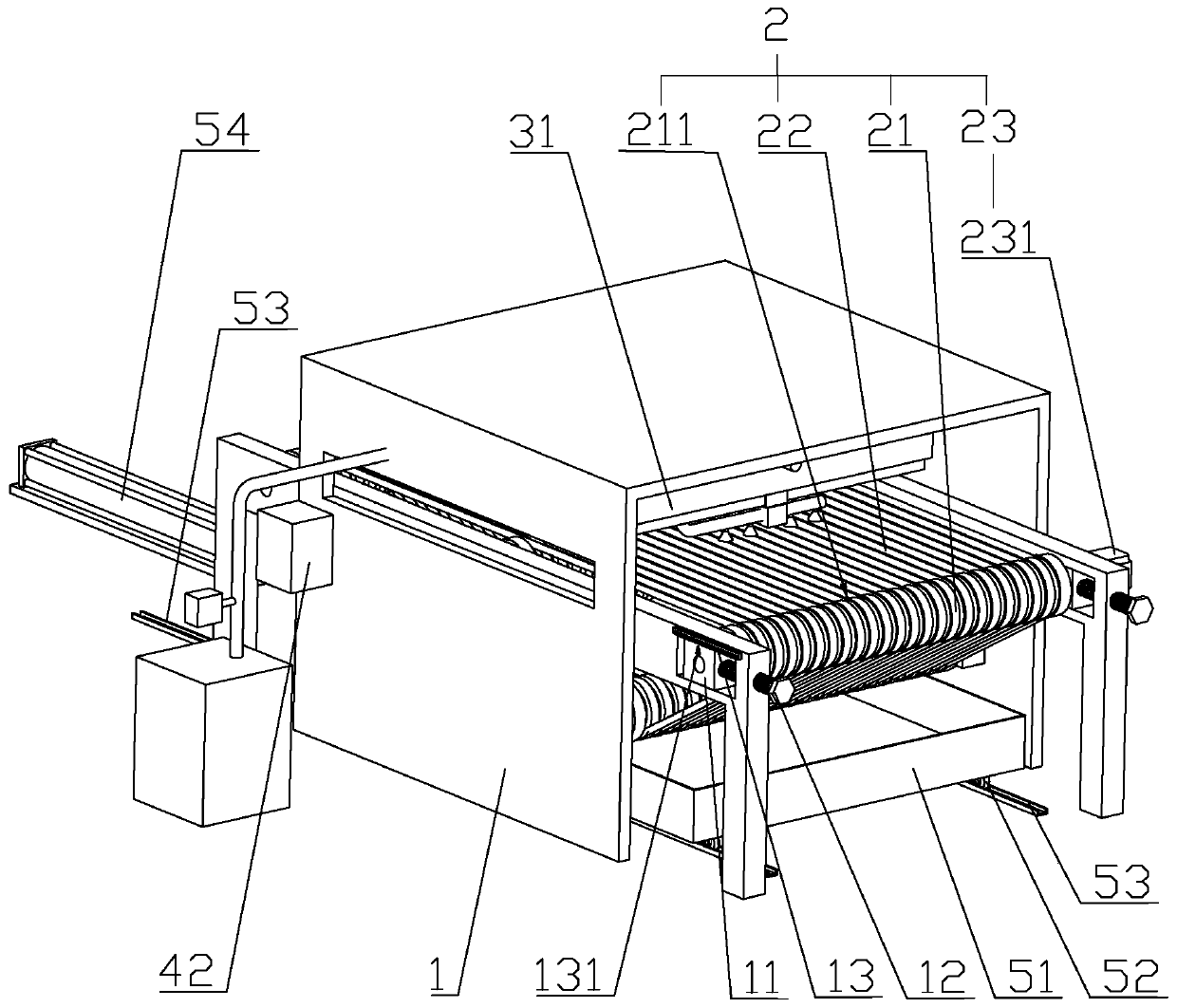

[0040]The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] A process for producing embossed leather disclosed by the invention comprises the following steps:

[0042] S100: Flatten the leather and put it into the leather grinding machine for grinding to reduce the uneven part of the top layer of leather. The grinding machine adopts the 116 type single-side grinding machine manufactured by Chaoyang Machinery to perform the grinding process on the leather .

[0043] S200: The leather is made of animal top layer leather. The animal top layer skin will have flaws due to external factors. For the aesthetics of the skin, after the mending cream is solidified, continue to be smoothed by a grinder. The mending cream is made by Youshone on the market. Apply repair paste to the gaps on the surface of the leather to fill them up, and vacuum iron the leather with an ironing machine to keep the surface of the fabric flat....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com