Assembly type steel structure integrated green building and design and installation process thereof

A green building and steel structure technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of delaying the construction period, affecting the quality of the building, not easy to correct, etc., to achieve high production efficiency and low total resource consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

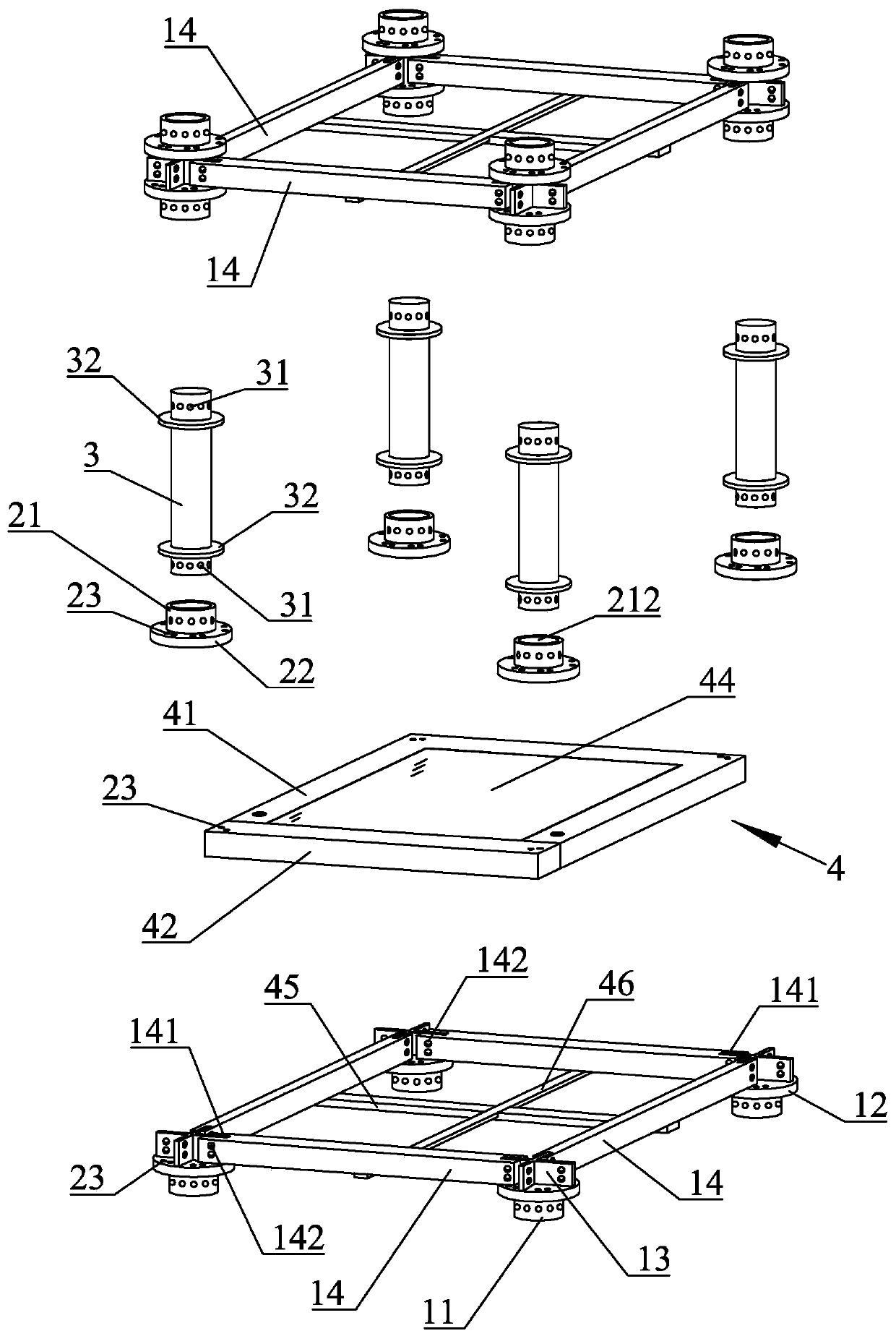

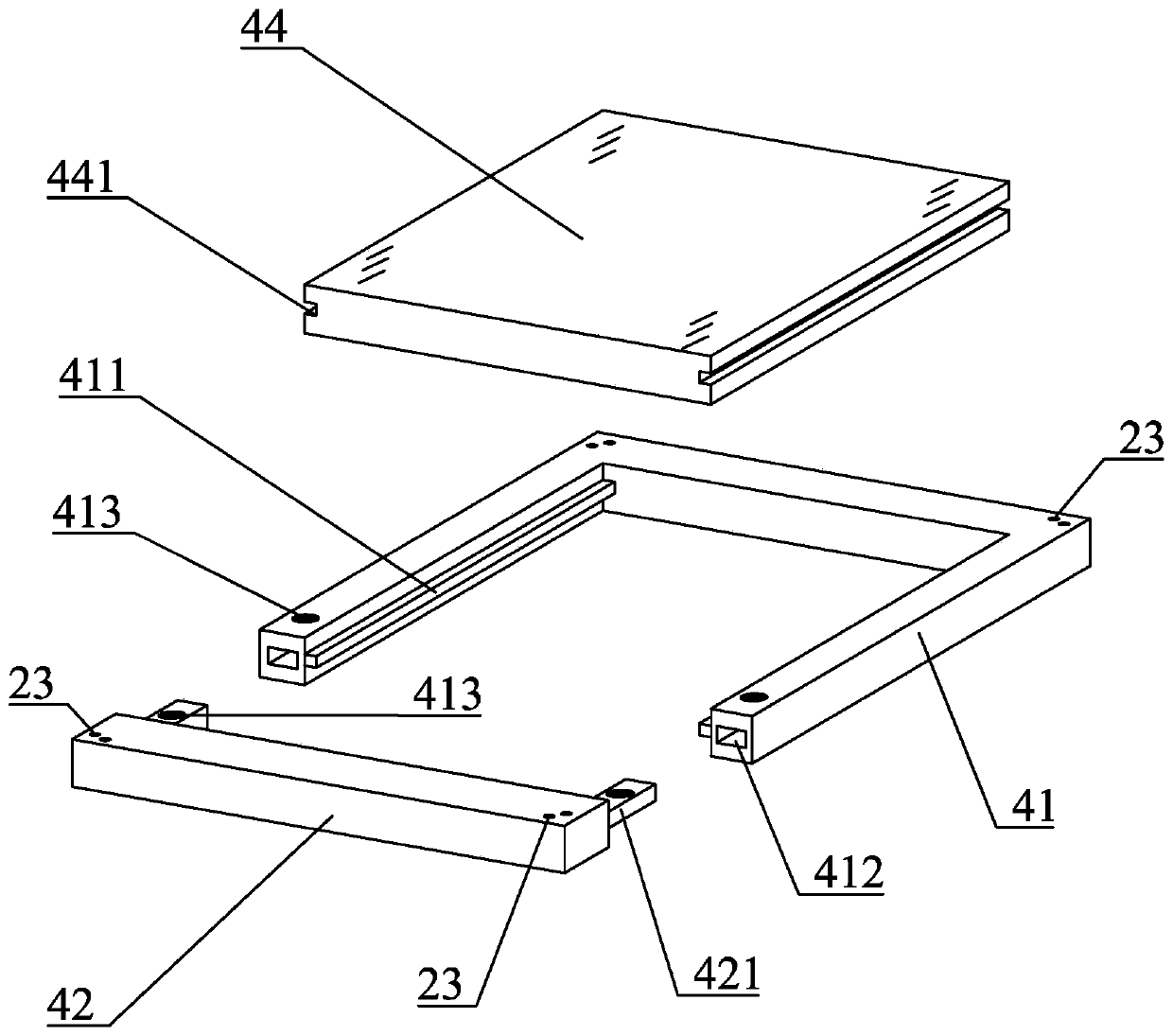

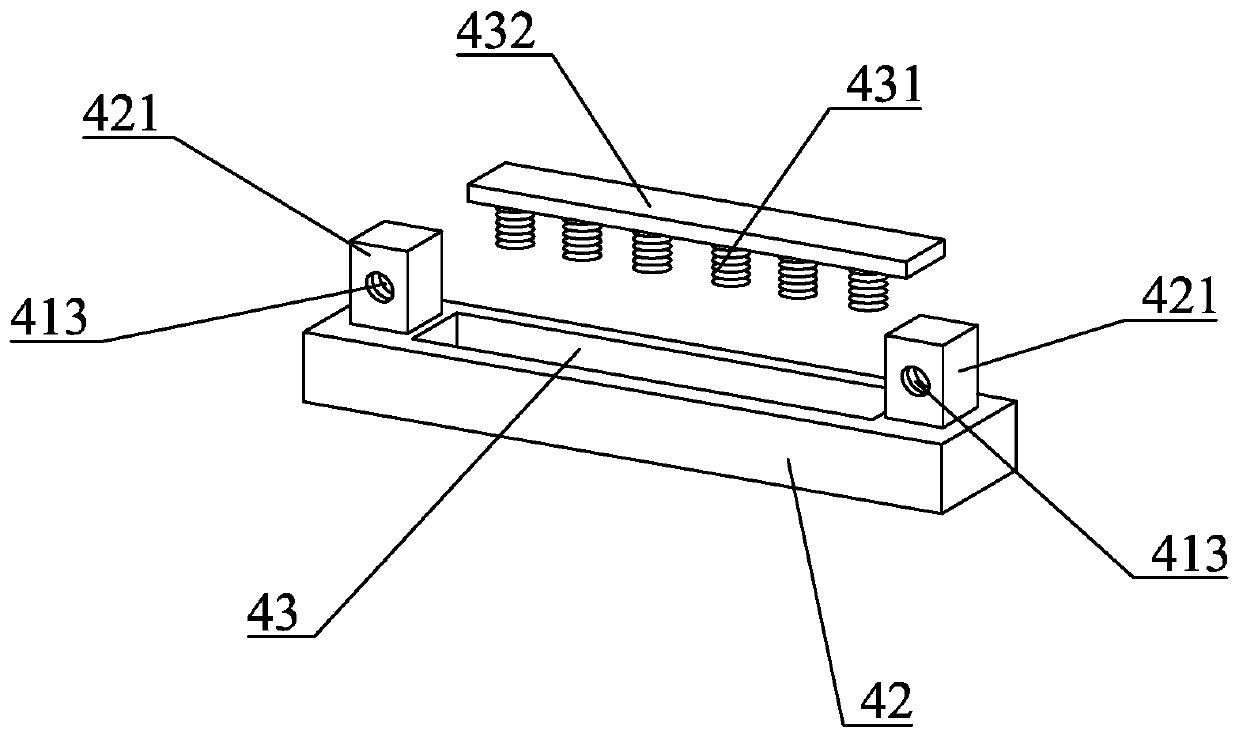

[0039] Such as Figure 1 to Figure 7 As shown, it is a prefabricated steel structure integrated green building related to the present invention, including a lower connecting seat 1, a beam 14, an upper connecting seat 2, a column 3 and a floor assembly 4; the lower connecting seat 1 includes a lower short column 11. The lower supporting plate 12 and the cross connecting plate 13, the lower short column 11 is fixedly set at the center of the lower bottom surface of the lower supporting plate 12, and the cross connecting plate 13 is arranged at the center of the upper surface of the lower supporting plate 12; the cross beam 14 is formed with a slot 141, and the slot 141 of the cross beam 14 is plugged into the cross connection plate 13; the cross connection plate 13 and the cross beam 14 are formed with a first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com