Integral laminated slab composite beam

A technology of laminated slabs and composite beams, applied in the direction of joists, girders, truss beams, etc., can solve the problems of insufficient integrity of prefabricated slabs, and achieve the effects of reducing the lack of integrity of components, firm connections, and simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

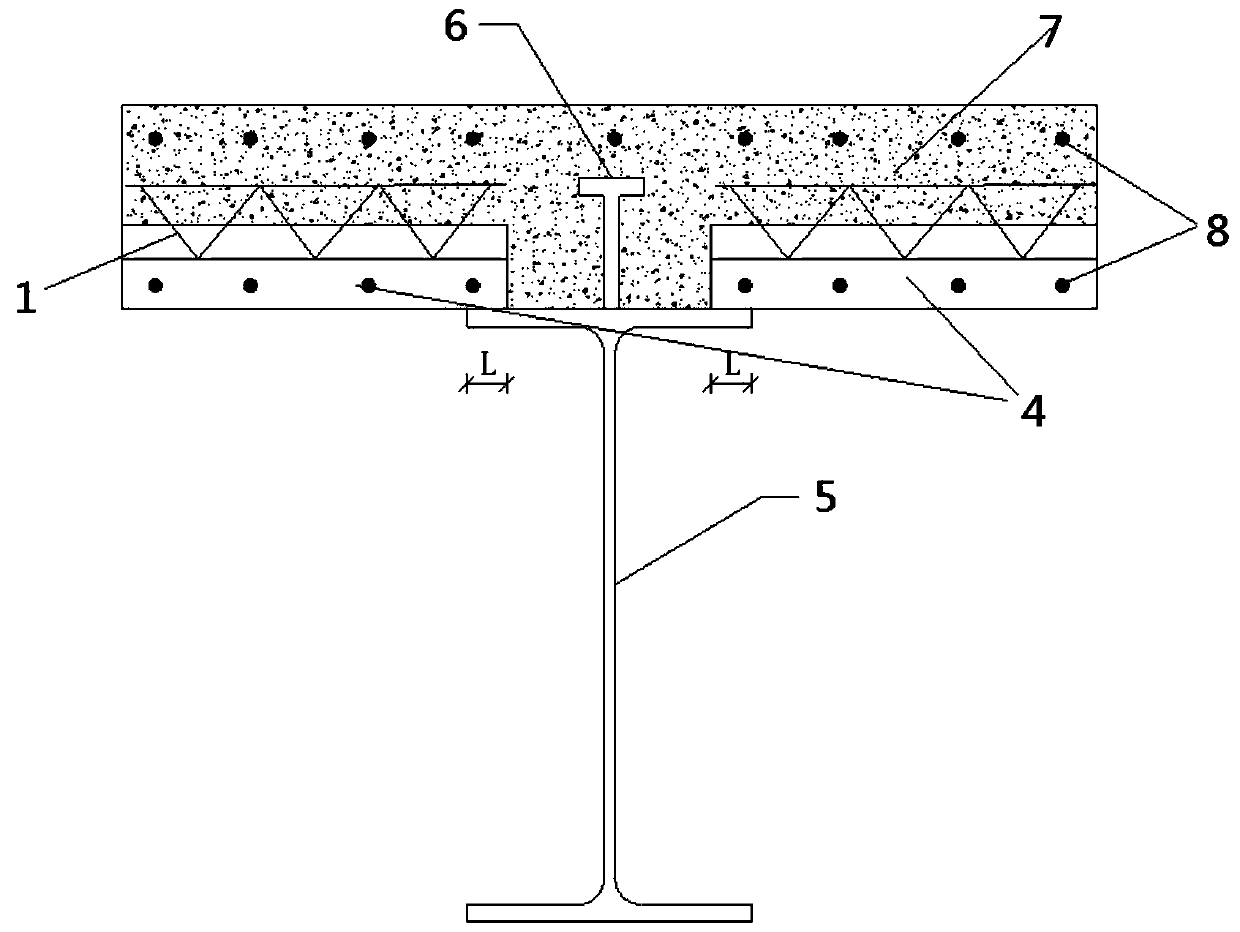

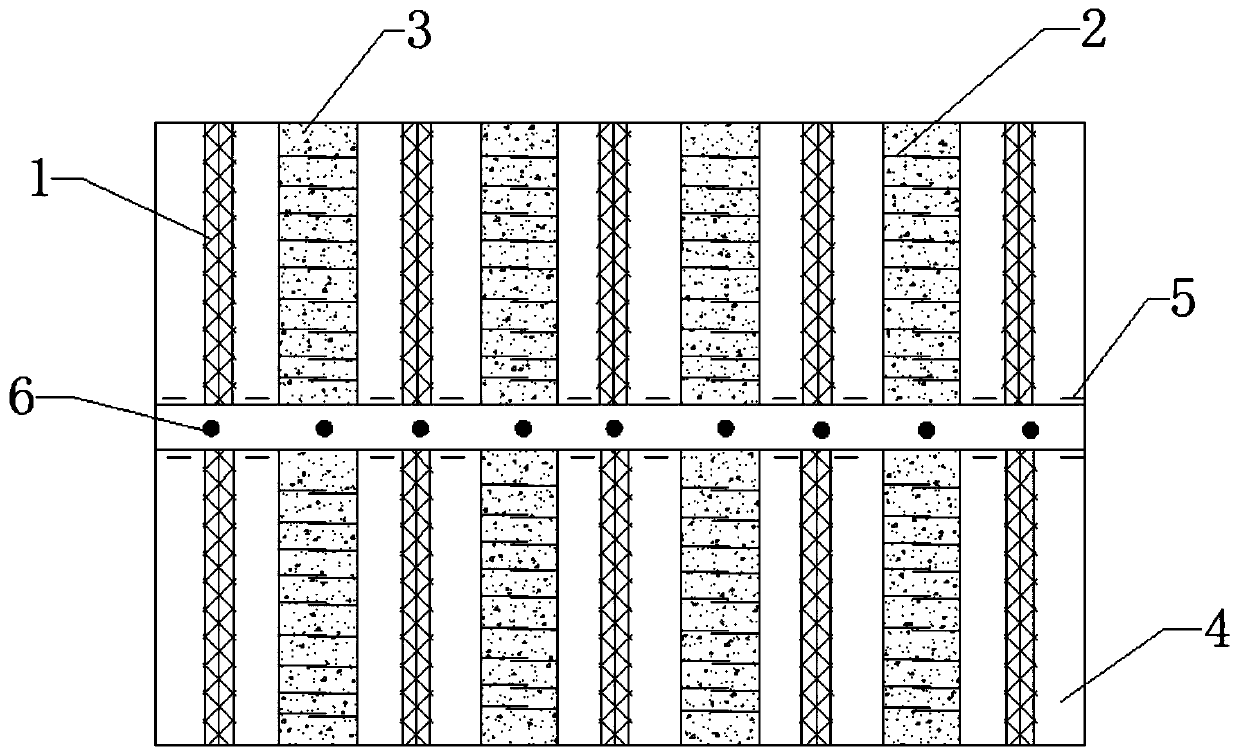

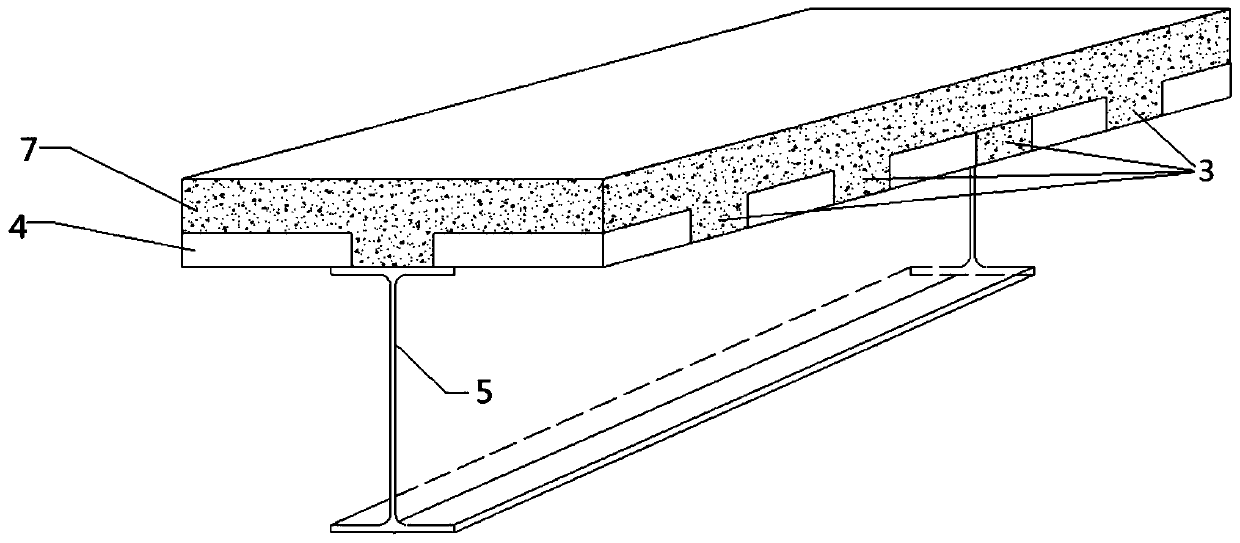

[0043] An integral laminated slab composite beam, comprising a plurality of composite sub-beams capable of being connected to each other, the composite sub-beams comprising a prefabricated layer, the prefabricated layer having a plurality of overlapping steel bars 2, and a plurality of prefabricated sub-beams The sides of the layers are provided with joints 3, and the overlapping steel bars 2 are exposed from the joints 3; the tops and sides of multiple composite sub-beams are covered and connected by pouring layers 7; the prefabricated layers and the pouring layers 7 They are connected by truss reinforcement 1. The pouring layer 7 is connected to at least one straight side of the steel beam 5 through a shear connector 6 . The solution disclosed in the present invention solves the problem of insufficient integrity of the prefabricated slab 4 by combining the prefabricated slab 4 with the pouring layer 7, uses the truss steel bar 1 as an auxiliary connection between the prefabr...

Embodiment 2

[0059] A method for manufacturing an integral laminated slab composite beam, comprising the following steps:

[0060] - weld the shear connector 6 on the upper flange of the steel beam 5;

[0061] -Processing the prefabricated slab 4, when the prefabricated slab 4 is processed, the truss reinforcement 1 needs to be pre-placed in the slab, a part of the truss reinforcement 1 is embedded in the prefabricated slab 4, and the other part is embedded in the pouring layer after the pouring layer is poured;

[0062] - Place one end of the prefabricated slab 4 on the upper flange of the steel beam 5, and the shelving size is set according to the design requirements.

[0063] -Leave a certain length of overlapping steel bars 2 at the splicing parts of adjacent prefabricated panels 4. The position of the overlapping steel bars 2 is also the joint 3 between adjacent prefabricated panels 4. A part of the formwork should be laid under the joints 3 .

[0064] - laying prefabricated slabs 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com