Construction device for building waterproof layer

A construction device and building waterproofing technology, applied in construction, protection device, building structure and other directions, can solve the problems of low construction efficiency, high labor cost, poor straightness of coiled material, etc., and achieve good cohesion, fast waterproof material, The effect of improving the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

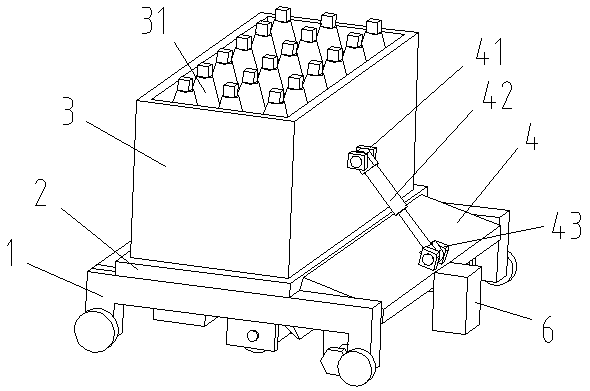

[0025] Such as Figure 1 to Figure 3 As shown, a building waterproof layer construction device according to the present invention is characterized in that it includes a trolley 1, and the trolley 1 adopts a flatbed trolley in the prior art, and the upper side of the trolley 1 is fixedly connected to the support seat plate 2, and The side is fixedly connected to the gas source box 3, and the gas source box 3 is equipped with oxygen and acetylene gas cylinders 31, and one side of the support seat plate 2 is connected to the base plate 4 by hinge rotation. One side of the air source box 3 is hinged and fixed to one end of the electric push-pull rod 42 through the first hinge seat 41, and the other end of the electric push-pull rod 42 is hinged and fixed to the base plate 4 through the second hinge seat 43, and the electric push-pull rod 42 controls the support of the substrate 4 along the Seat plate 2 one sides rotate.

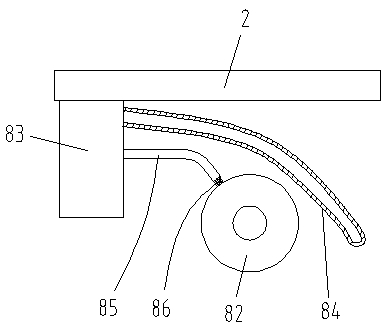

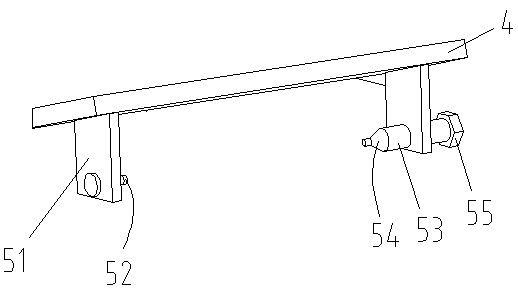

[0026] The lower side of the base plate 4 is provided with...

Embodiment 2

[0032] The heating device in Embodiment 1 can be replaced with the following structure: the heating device includes two parallel mounting plates 61, both of which are welded and fixed to the base plate 4, and a guide rod 62 is fixedly connected between the two mounting plates 61 , Rotate between two mounting plates 61 and connect the threaded mandrel 63, one end of the threaded mandrel 63 runs through the mounting plate 61 and extends to the outside of the mounting plate 61, the mounting plate 61 is equipped with a motor 64 for driving the threaded mandrel 63 to rotate, the motor The main shaft of 64 is coaxial with screw mandrel 63 and is fixedly connected.

[0033] The heating device also includes a slider 71, one side of the slider 71 is provided with a sliding hole 711 and a screw threaded hole 712, the guide rod 62 passes through the sliding hole 711, and the screw 63 is in the screw threaded hole 712 Threaded connection, the slider 71 can slide back and forth along the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com