Two-gear mechanical automatic transmission for electric vehicle

An automatic transmission and electric vehicle technology, applied in the field of automobile transmission system, can solve the problems of poor transmission scalability, poor shifting performance, output shaft, and uneven force on bearings, so as to reduce product cost and development cycle, good inheritance, The effect of reducing fever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

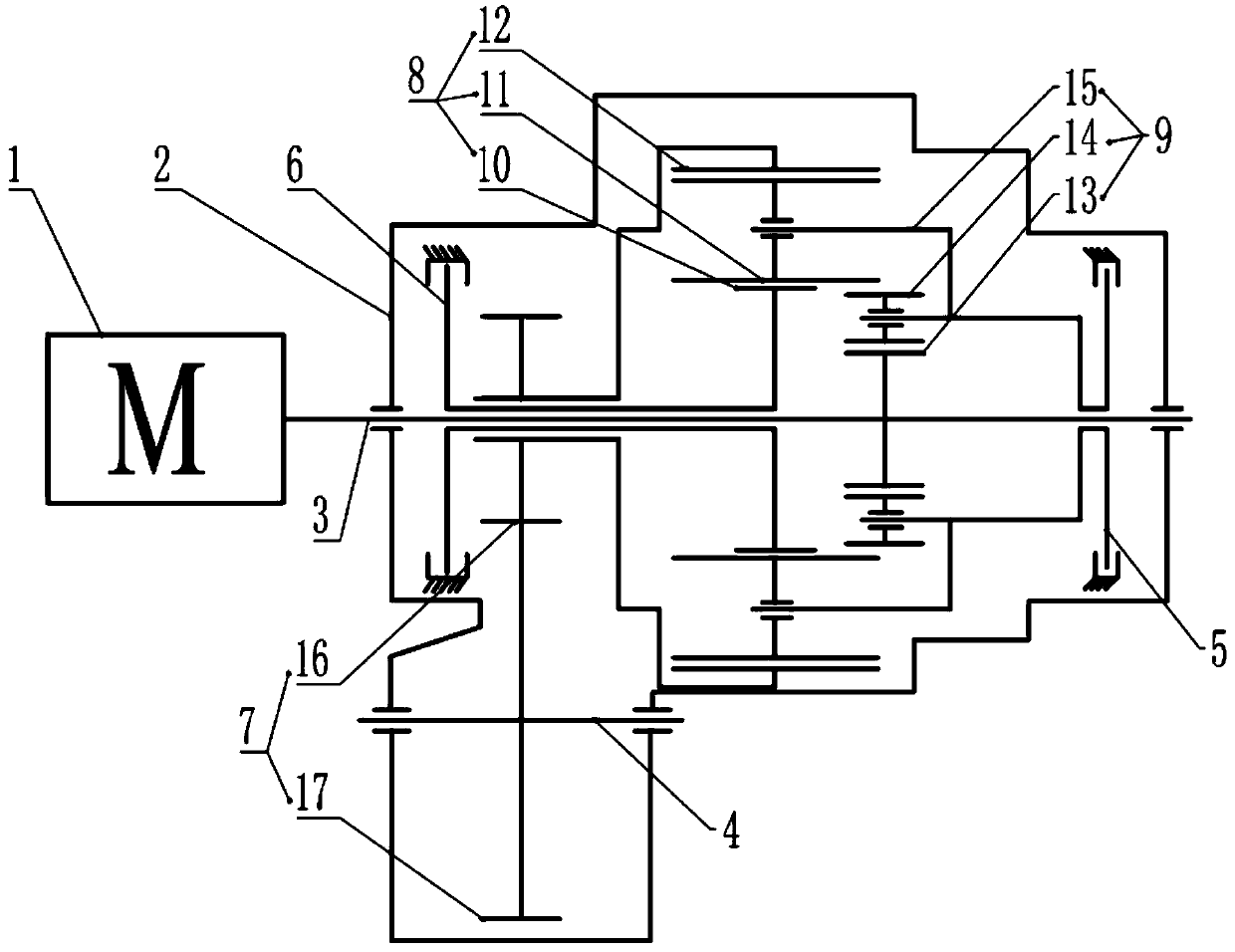

Embodiment 1

[0035] Embodiment one is basically as figure 2 As shown, the two-speed mechanical automatic transmission for electric vehicles includes a drive motor 1, a casing 2, and an input shaft 3 and an output shaft 4 for power transmission. The casing 2 includes a double-row, two-stage planetary gear set, a first The brake 5, the second brake 6 and the first gear set 7; the double-row double-stage planetary gear set includes a front row planetary gear set 8 and a rear row planetary gear set 9, and the motor shaft of the drive motor 1 is connected to the input shaft 3 through a spline , the output shaft 4 is connected with the wheel of the electric vehicle through a coupling.

[0036] The front row planetary gear set 8 includes the front row sun gear 10, the front row planetary gear 11 and the ring gear 12, the rear row planetary gear set 9 includes the rear row sun gear 13, the rear row planetary gear 14 and the planet carrier 15, and the rear row planetary gear 14 and the front plan...

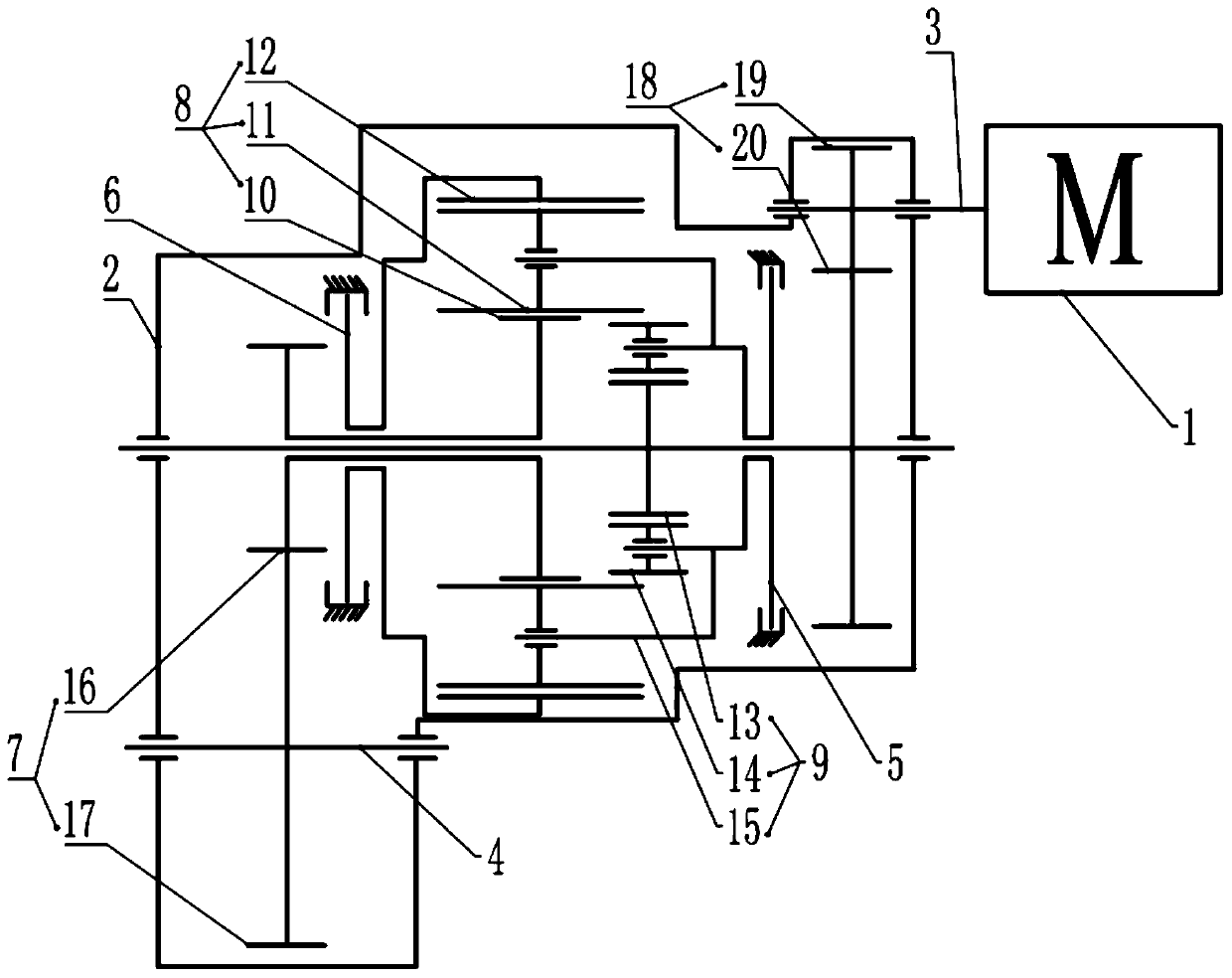

Embodiment 2

[0062] Embodiment two is basically as image 3 As shown, there are two differences between Embodiment 2 and Embodiment 1. The first point is to change the braking components of the second brake 6. In Embodiment 2, the second brake 6 is used to brake the ring gear 12, and the double row The output of the double-stage planetary gear set is the front sun gear 10; secondly, in the second embodiment, the second gear set 18 is added, the second gear set 18 is located in the housing 2, and the second gear set 18 includes the second active The gear 19 and the second driven gear 20 , the second driving gear 19 is fixedly connected with the input shaft 3 , and the second driven gear 20 is fixedly connected with the rear sun gear 13 .

[0063] The gear ratio between the second driven gear 20 and the second driving gear 19 of the second gear set 18 is 2.5.

[0064] Specific working process:

[0065] When in neutral, the control unit of the electric vehicle controls both the first brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com