Method for testing optimal spring stiffness coefficient of elastic hydrofoil of wave glider

A test method and stiffness coefficient technology, which is applied in the field of shipbuilding and ocean engineering, can solve the problems of inaccurate positioning, large changes in the motion speed of wave glider, and the inability of trailer equipment to provide the heave force and motion effect of the mother ship on the underwater glider. Achieve the effects of avoiding motion interference, easy positioning, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

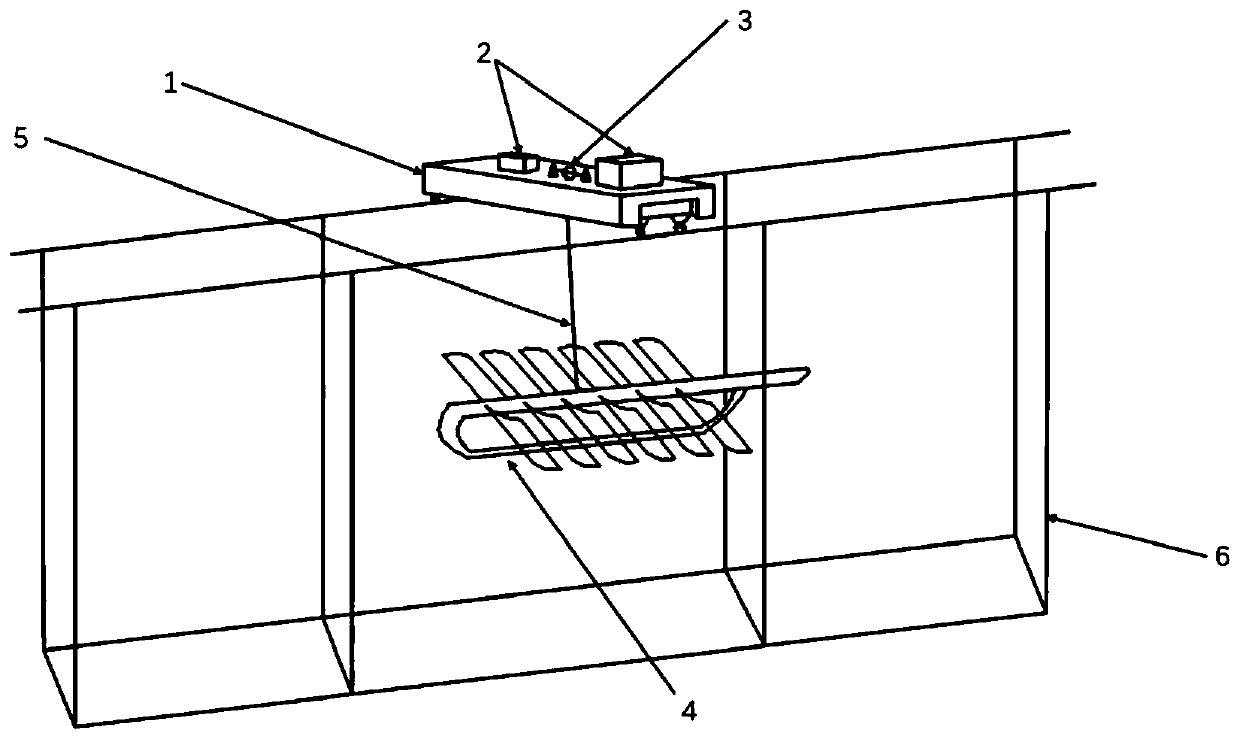

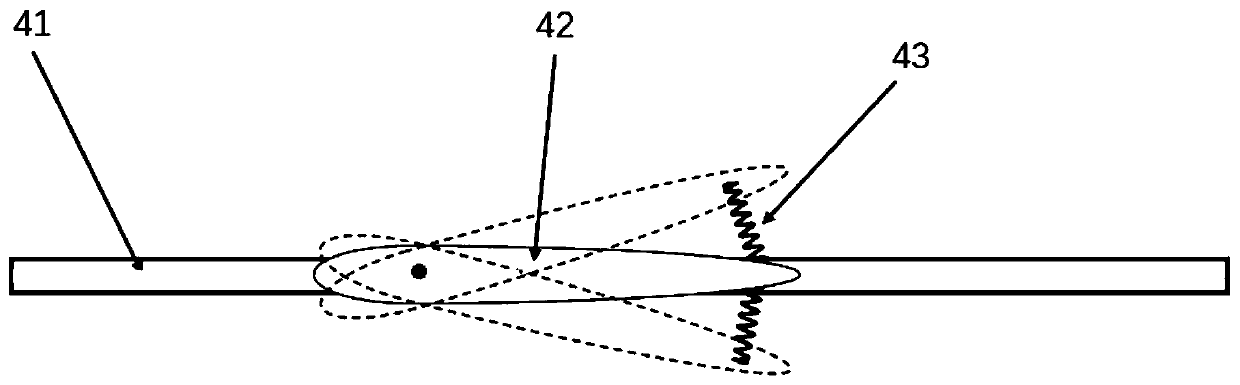

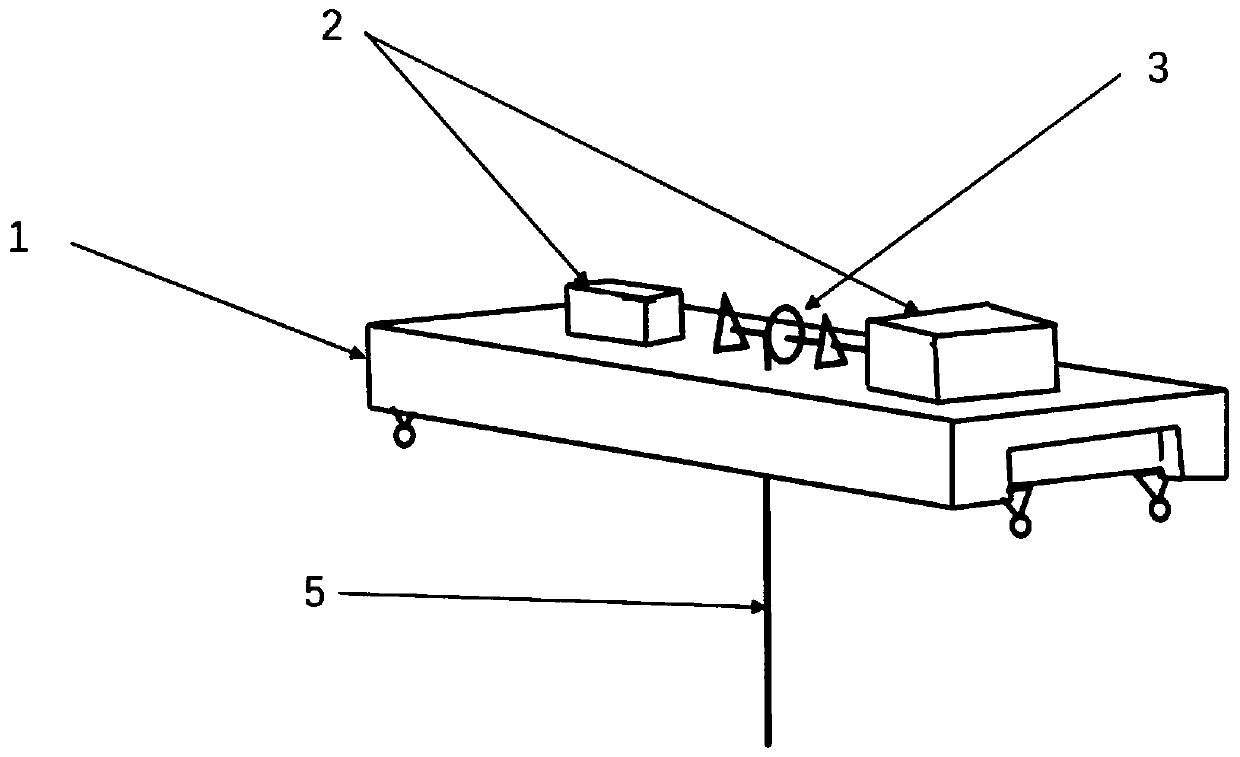

[0039] Such as figure 1 As shown, the test device required in this test method includes a vertical excitation trolley, an underwater tractor model 4, a traction line 5 and a water tank 6; the vertical excitation trolley includes a trailer carrier 1, a heave excitation control device 2 and a sheave 3; Such as figure 2 As shown, the underwater tractor model 4 used in this test method includes a body 41 , an elastic hydrofoil 42 and a spring 43 .

[0040] When conducting the test, first configure the test device used for the test:

[0041] 1. Fix and wind the upper end of the traction line 5 on the sheave 3;

[0042] 2. Fix the lower end of the traction line 5 at the physical center of gravity of the underwater tractor model 4;

[0043] 3. Install the vertical excitation trolley on the guide groove of the water tank 6;

[0044] 4. Place the underwater tractor model 4 in the water tank 6 and completely submerge it in the water.

[0045] In the above configuration process, th...

Embodiment 2

[0048]Install the spring 43 studied in this test method between the body 41 and the elastic hydrofoil 42, and ensure that after the spring 43 is installed, the elastic hydrofoil 42 remains horizontal under the action of the spring 43 while the body 41 remains horizontal in the water. After the installation is completed, use the similarity law to calculate the amplitude of the underwater traction machine model 4 corresponding to the real sea state wave height in the test, and obtain the corresponding power shaft rotation angle by the calculation method of the above amplitude, and control the heave excitation control device 2 through the excitation control set to produce an amplitude that meets the test requirements. At the same time, it should be noted that the amplitude of the underwater tractor model 4 must be less than the depth of the underwater tractor model 4 being immersed in water, so as to ensure that the heave excitation control device 2 can control the underwater tract...

Embodiment 3

[0050] When the heave excitation control device 2 applies heave excitation to the underwater tractor model 4, the vertical excitation trolley will move forward, because the edge surface of the water tank 6 for the sliding of the vertical excitation trolley is not completely flat, and the length of one grid of the water tank 6 is only 1.5 meters, so the time required for the car to pass through the three grids is measured, and its average speed is calculated to characterize the performance of the elastic hydrofoil of the wave glider. At this time, record the average time required for the vertically excited car to pass through the 3-grid water tank, and calculate the movement speed of the vertically excited car under the specific stiffness coefficient of the spring 43 and the specific amplitude of the underwater tractor model 4, so as to characterize The sporty performance of a wave glider. Using the control variable method, replace the spring 43 with different stiffness coeffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com