Winding coil based on rhombic dispensing soft composite material and transformer

A composite material, winding coil technology, applied in the field of transformers, can solve the problem of large thickness of the insulating layer, and achieve the effects of meeting safety requirements, improving the quality of power supply voltage, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

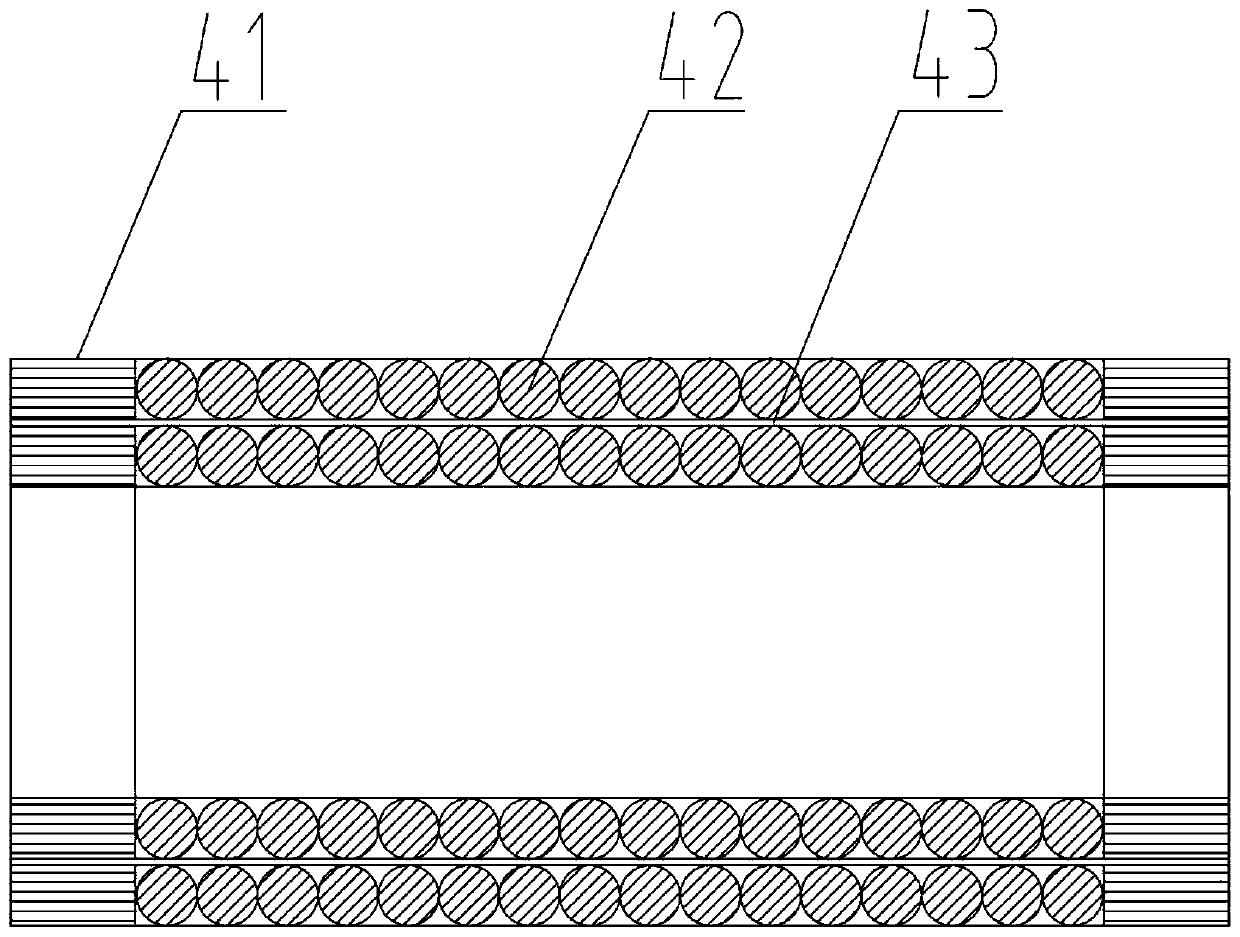

[0027] The present invention provides a winding coil based on lattice dispensing soft composite material, see figure 1 , including a coil 42, an insulating layer 41 and an insulating terminal 43, the coil 42 includes several turns and an insulating layer 41 is arranged between every two turns, the insulating layer 41 is a piece of thick ribbed glue-dispensing soft composite material, and the insulating terminal 43 has Two, respectively located at two ends of the winding coil, the width of the coil 42 and the insulating layer 41 is determined by the distance between the two insulating terminals 43 .

[0028] The manufacturing process of the winding coil is as follows: when the coil 42 is wound on one layer, the insulating terminal 43 is placed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com