Current collector, current collector manufacturing method, electrode plate and lithium ion battery

A technology of electrode pole piece and manufacturing method, applied in the direction of electrode carrier/current collector, non-aqueous electrolyte storage battery, secondary battery, etc. The effect of thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

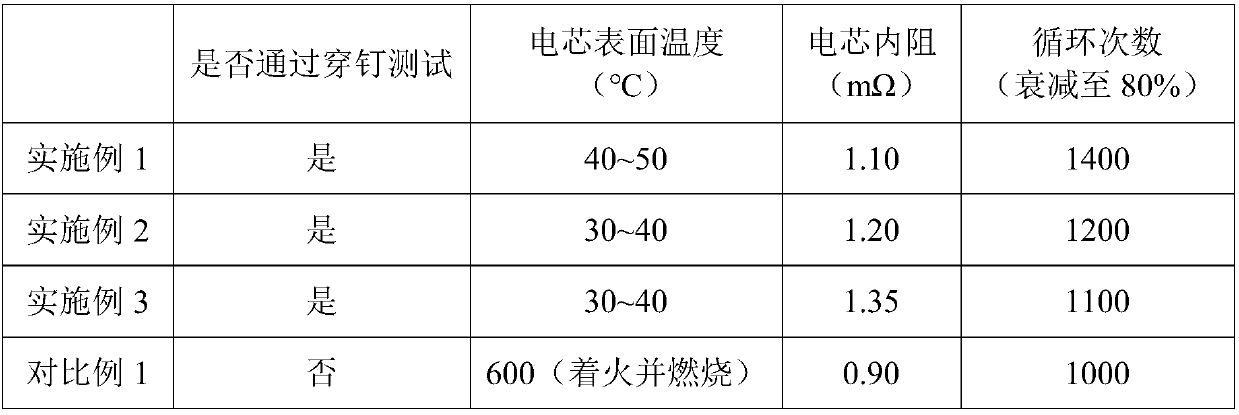

Embodiment 1

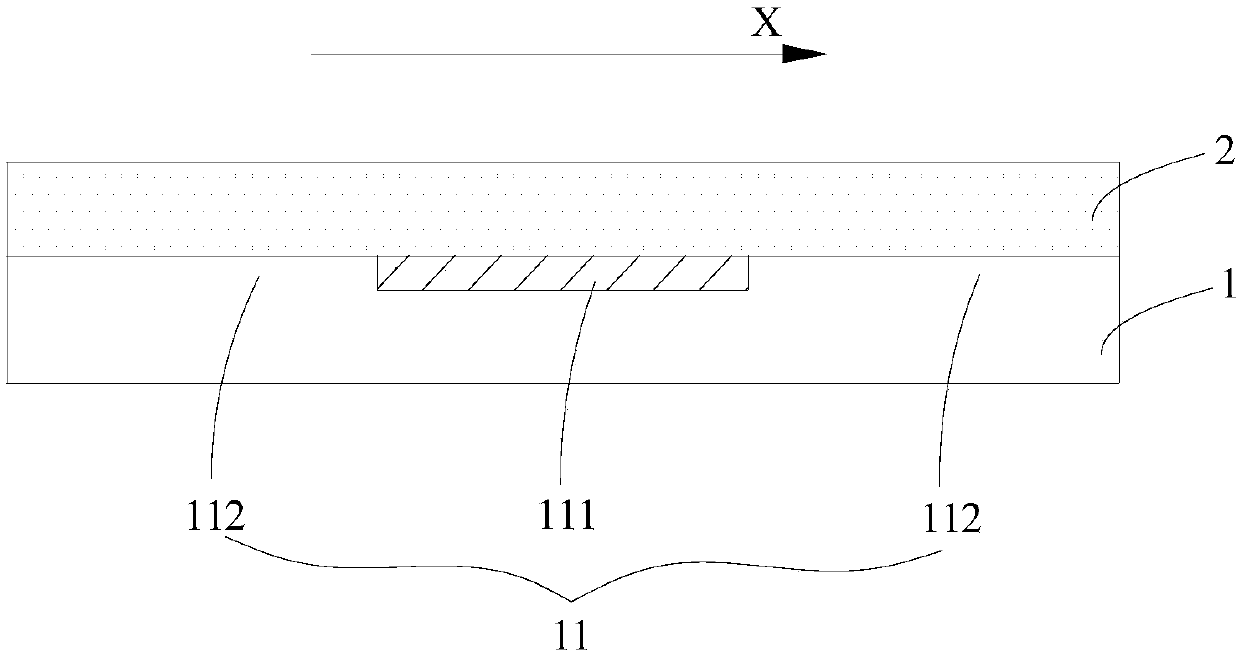

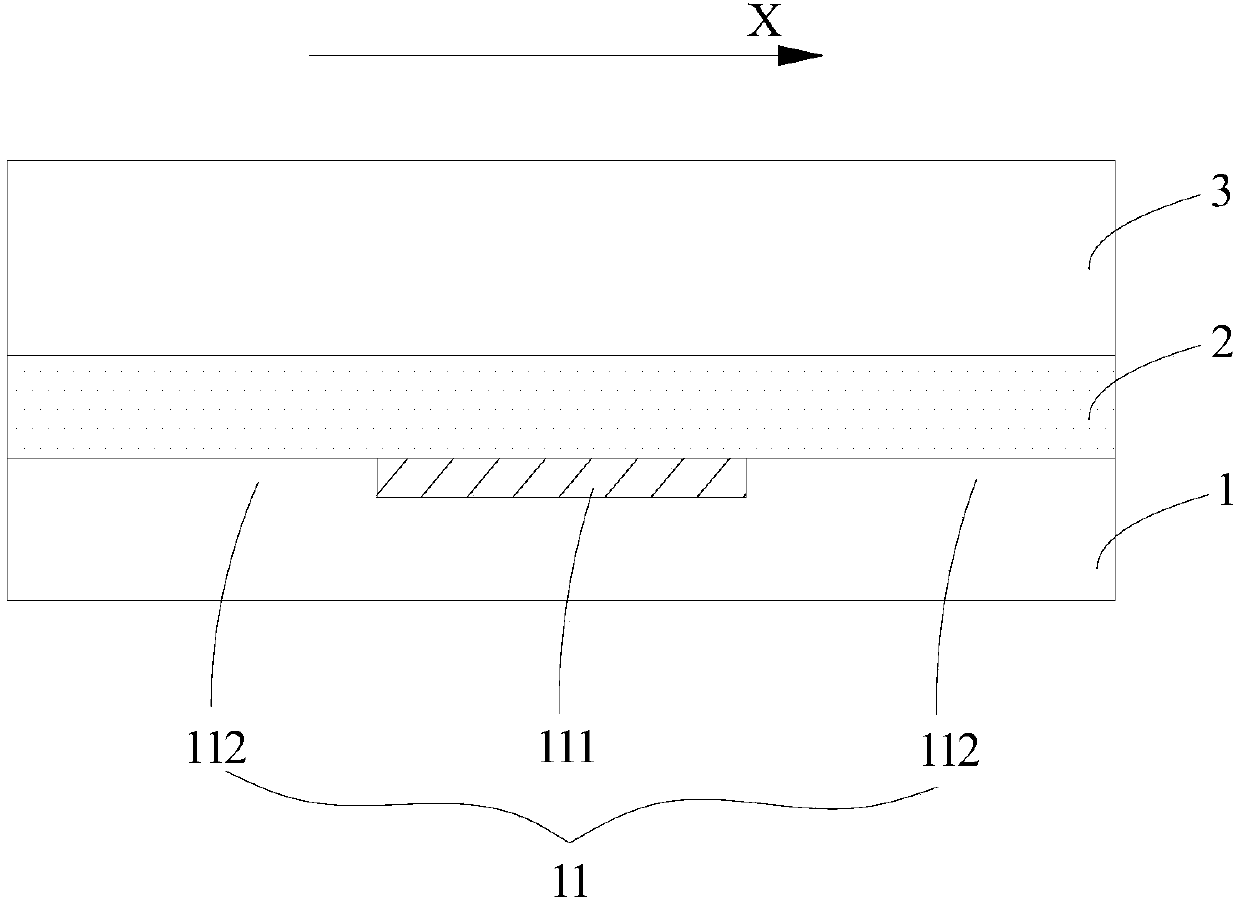

[0067] Hard shell batteries, the cathode pole piece adopts figure 1 The current collector shown has a width of 80mm, the width of the first region, that is, the oxidation region, is 35mm, and the surface resistance of the aluminum foil is 3Ω·cm 2 , the thickness of the undercoat layer is 6 μm.

Embodiment 2

[0069] On the basis of Example 1, the width of the first area on the surface of the aluminum foil, ie, the oxidized area, was adjusted from 35 mm to 45 mm, and the widths of the two second areas, ie, the two non-oxidized areas, were correspondingly reduced by 5 mm. Other manufacturing specifications are consistent with embodiment 1.

Embodiment 3

[0071]On the basis of Example 1, increase the degree of oxidation of the first region on the surface of the aluminum foil, that is, the oxidation degree of the oxidized region, and make the surface resistance of the aluminum foil from 3 Ω cm 2 Increased to 10Ω·cm 2 . Other manufacturing specifications are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com