Predictive dead time generating circuit

A dead time and circuit generation technology, applied in electrical components, regulating electrical variables, high-efficiency power electronic conversion, etc., can solve the problem that the dead time cannot reach the optimal value, and achieve the effect of reducing power consumption and optimizing length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

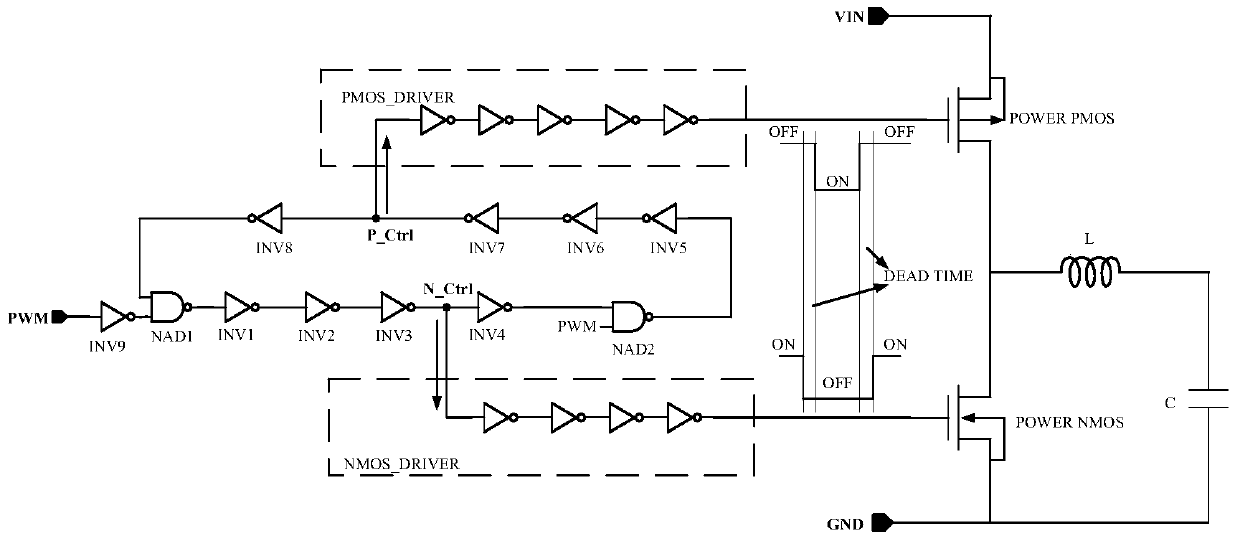

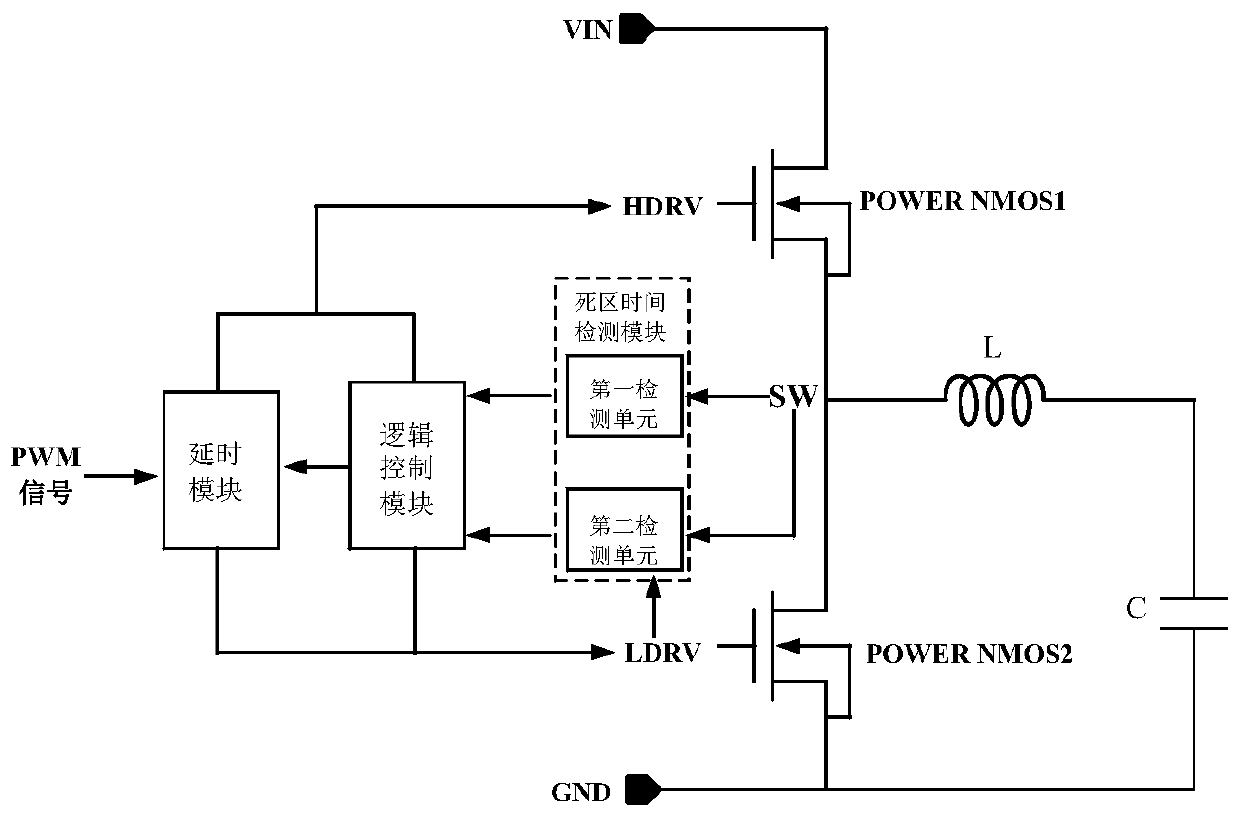

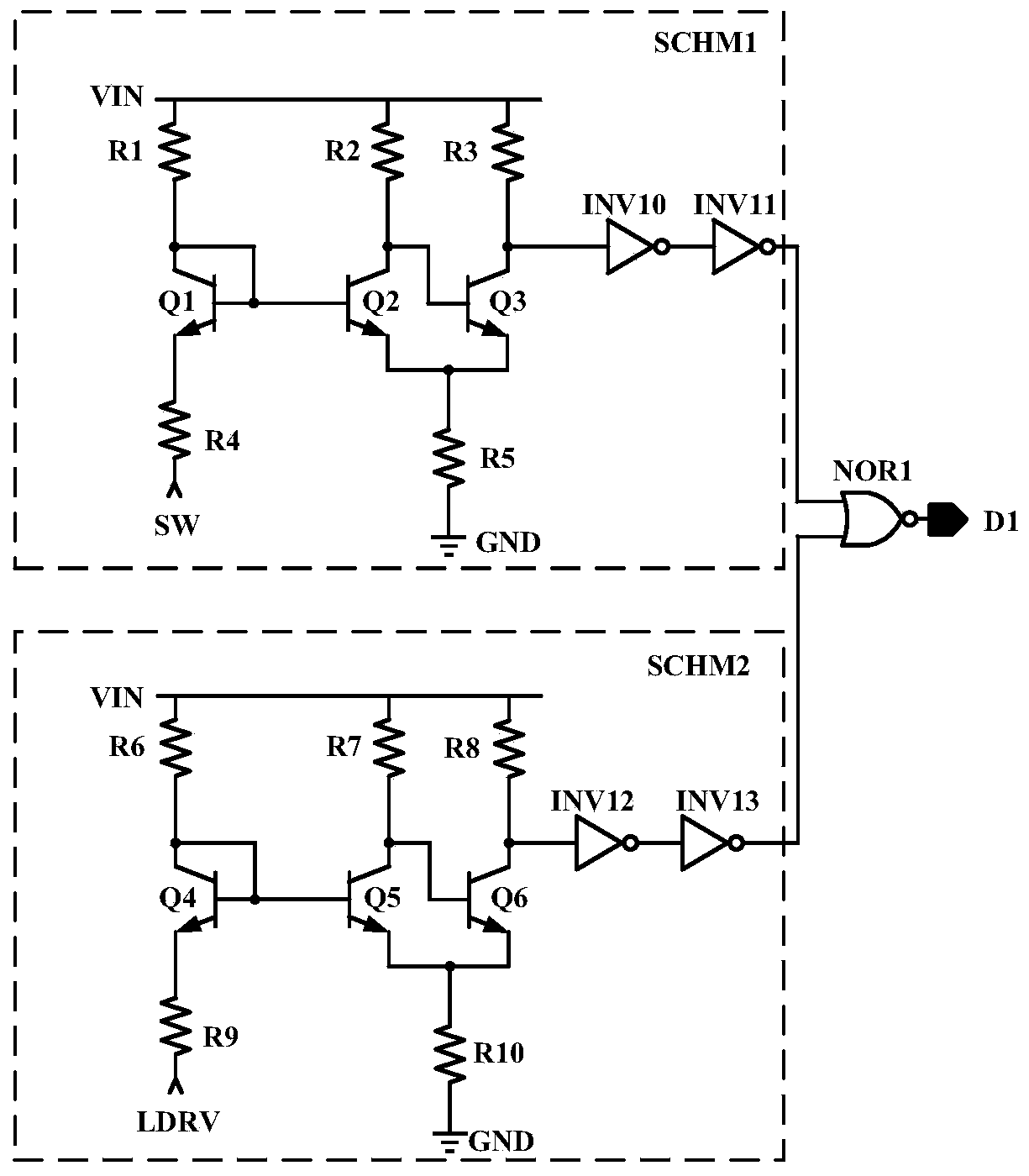

[0053] The idea of the predictive dead-time generation circuit proposed by the present invention is to judge whether the dead-time reaches an optimal value through the working state of the current cycle, so as to determine whether the dead-time of the next cycle will increase or decrease. like figure 2 The schematic diagram of the dead time detection circuit is shown, and the predictive dead time generation circuit includes three parts: dead time detection module, logic control module and delay module. The pulse width modulation signal PWM of the DC-DC converter is delayed by the delay module and combined with the signal generated by the logic control module to generate the upper power tube drive signal HDRV and the lower power tube drive signal LDRV. The dead time detection module is used to detect the dead time when the upper power tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com