Modifier, method for preparing same, and modified conjugated diene-based polymer comprising same

A modifier, alkenyl technology, applied in the field of modified conjugated diene polymers, can solve the problems of insufficient effect, low affinity, poor dispersibility, etc., and achieve improved mixing performance, excellent tensile strength, and good processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

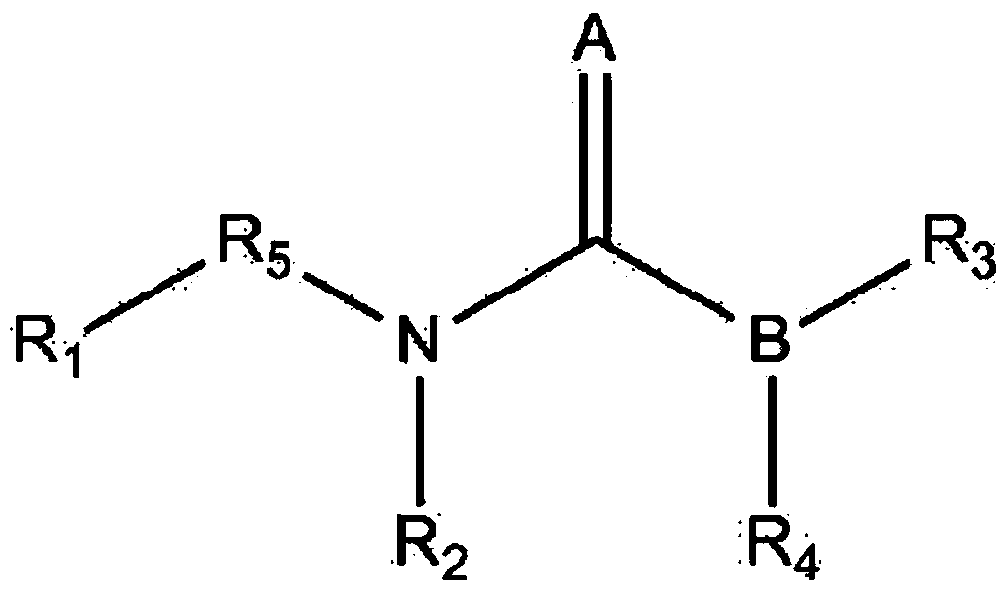

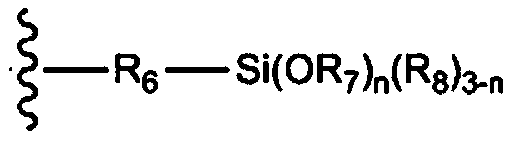

[0101] The production method according to one embodiment of the present invention is characterized in that it includes: reacting a compound represented by the following formula 2 with a compound represented by the following formula 3 (method 1); or making a compound represented by the following formula 2 A compound represented by Formula 3 below is reacted, and a compound represented by Formula 4 below and a basic compound are added and reacted (Method 2).

[0102] [Formula 2]

[0103]

[0104] [Formula 3]

[0105]

[0106] [Formula 4]

[0107] R 2 -Y

[0108] In formula 2 to formula 4, R 1 to R 5 And the definitions of A and B are the same as defined in formula 1, Y is CN, Cl, F or Br.

[0109] In other words, the preparation method of the modifying agent according to one embodiment of the present invention may be performed by method 1 or method 2 according to the desired modifying agent.

[0110] The compound represented by Formula 2 may be, for example, a compo...

preparation Embodiment 1

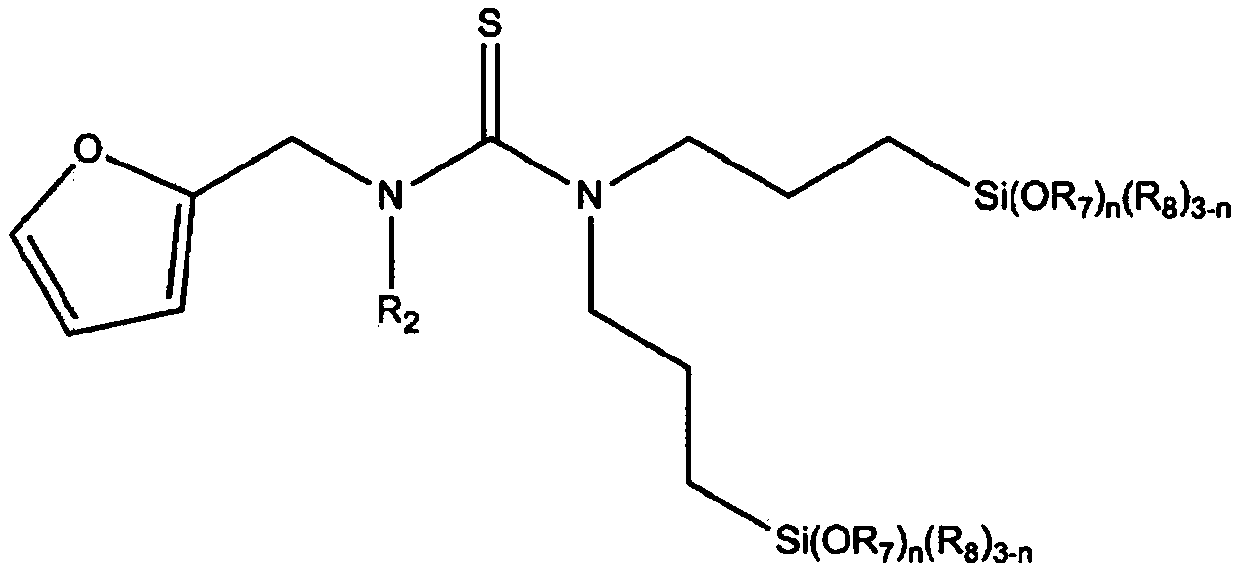

[0218] Preparation Example 1: Preparation of modifier represented by formula i

[0219]To a 1 L round bottom flask connected with a Schlenk line, 0.1 mol (13.92 g) of the compound represented by Formula 2-1 was added, the pressure was reduced and moisture was completely removed. Then, under an argon atmosphere, 500 ml of dichloromethane was added and 0.095 mol (40.44 g) of the compound represented by Formula 3-1 was added, followed by stirring and reacting at room temperature for 4 hours. Then, 0.12 mol (13.04 g) of the compound represented by formula 4-1 and 0.15 mol (15.18 g) of triethylamine were added thereto at low temperature, and stirred at room temperature for 24 hours to prepare the modified compound represented by formula i sex agent. After that, low-boiling point by-products and unreacted substances were removed using a rotary evaporator, and extraction was performed with hexane / acetonitrile to obtain an isolated modifier represented by formula i. observe 1 H and...

preparation Embodiment 2

[0230] Preparation Example 2: Preparation of modifier represented by formula (ii)

[0231] 0.1 mol (12.30 g) of the compound represented by Formula 2-2 was added to a 1 L round bottom flask connected with a Schreck line, the pressure was reduced and moisture was completely removed. Then, under an argon atmosphere, 500 ml of dichloromethane was added and 0.095 mol (40.44 g) of the compound represented by Formula 3-1 was added, followed by stirring and reacting at room temperature for 4 hours. Then, 0.12 mol (13.04 g) of the compound represented by formula 4-1 and 0.15 mol (15.18 g) of triethylamine were added thereto at low temperature, and stirred at room temperature for 24 hours to prepare the compound represented by formula (ii) modifiers. After that, low-boiling point by-products and unreacted substances were removed using a rotary evaporator, and extraction was performed with hexane / acetonitrile to obtain an isolated modifier represented by formula (ii). observe 1 H and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com