Automatic bolt tightening device of six-axis robot

An automatic tightening device and six-axis robot technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low tightening efficiency and unreliable tightening quality, reduce labor intensity, improve accuracy and assembly quality , The effect of shortening the installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

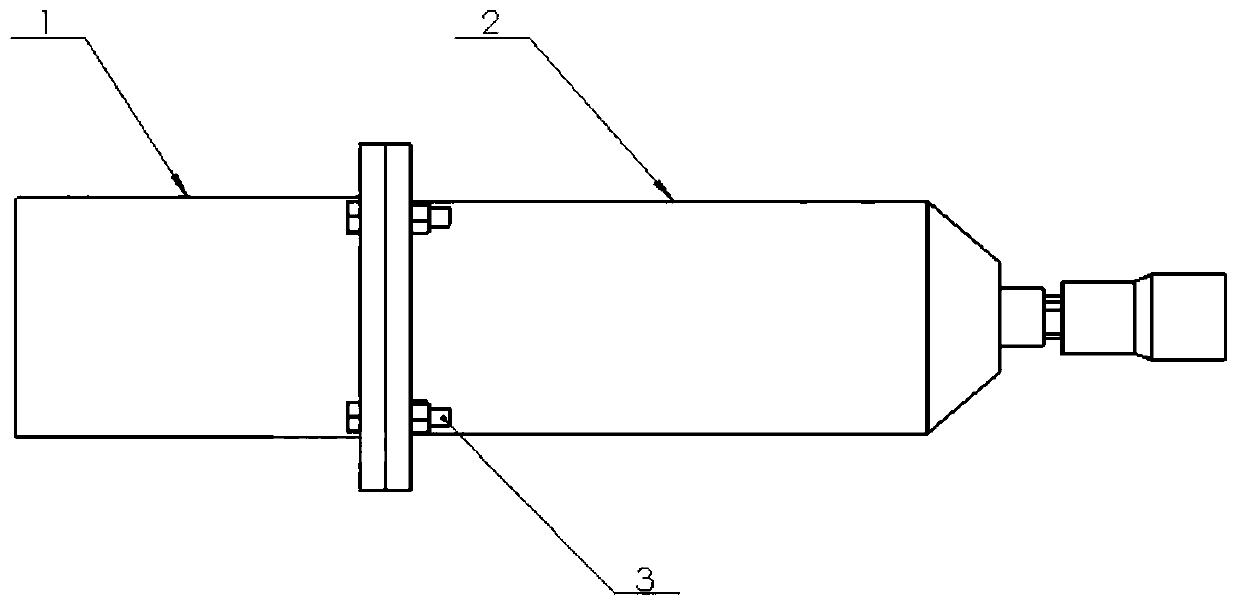

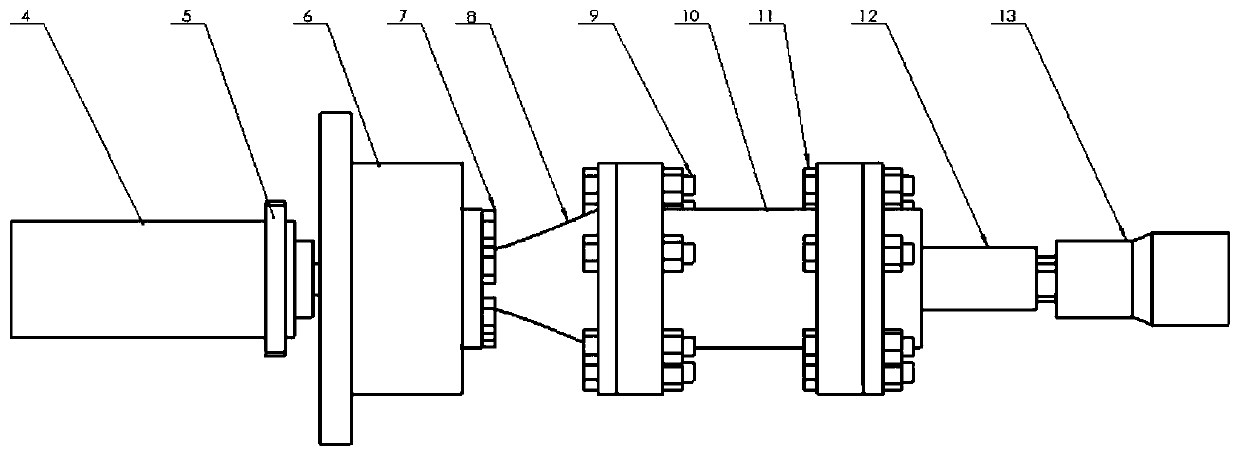

[0012] See Figure 1-4 , a six-axis robotic bolt automatic tightening device of the present invention includes: a rear end of the housing 1, a front end of the housing 2, an AC servo motor 5, a harmonic reducer 6, a variable diameter flange 8, a torque sensor 10, an output shaft 12 and a sleeve Barrel 13.

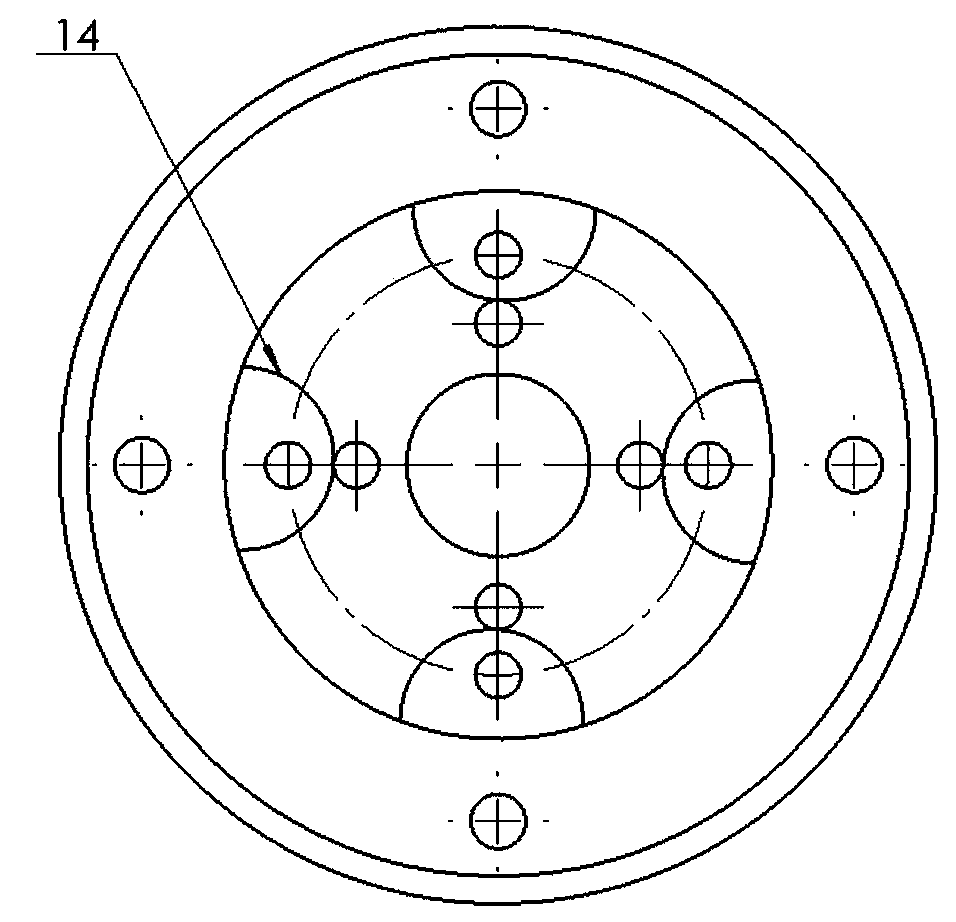

[0013] The rear end 1 of the housing is connected to the end flange 15 of the six-axis robot through bolts, and the AC servo motor 5 is connected to the baffle plate 14 inside the rear end of the housing through bolts; the harmonic reducer 6 is connected to the AC servo motor through keys. The motor 5 is axially connected, and is fixedly connected radially through bolts; the reducing flange 8 is connected to the harmonic reducer 6 through bolts 7, and the torque sensor 10 is connected to the reducing flange 8 through bolts 9; The output shaft 12 is connected with the torque sensor 10 through the bolt 11, and the output shaft 12 is connected with the sleeve 13 by an O-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com