Low-permeability fuel pipe extrusion production equipment

A technology for production equipment and fuel pipes, which is applied in the field of low-permeability fuel pipe extrusion production equipment, which can solve the problems of reducing automobile pollution emissions and fuel pipes failing to meet the emission requirements, and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0030] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

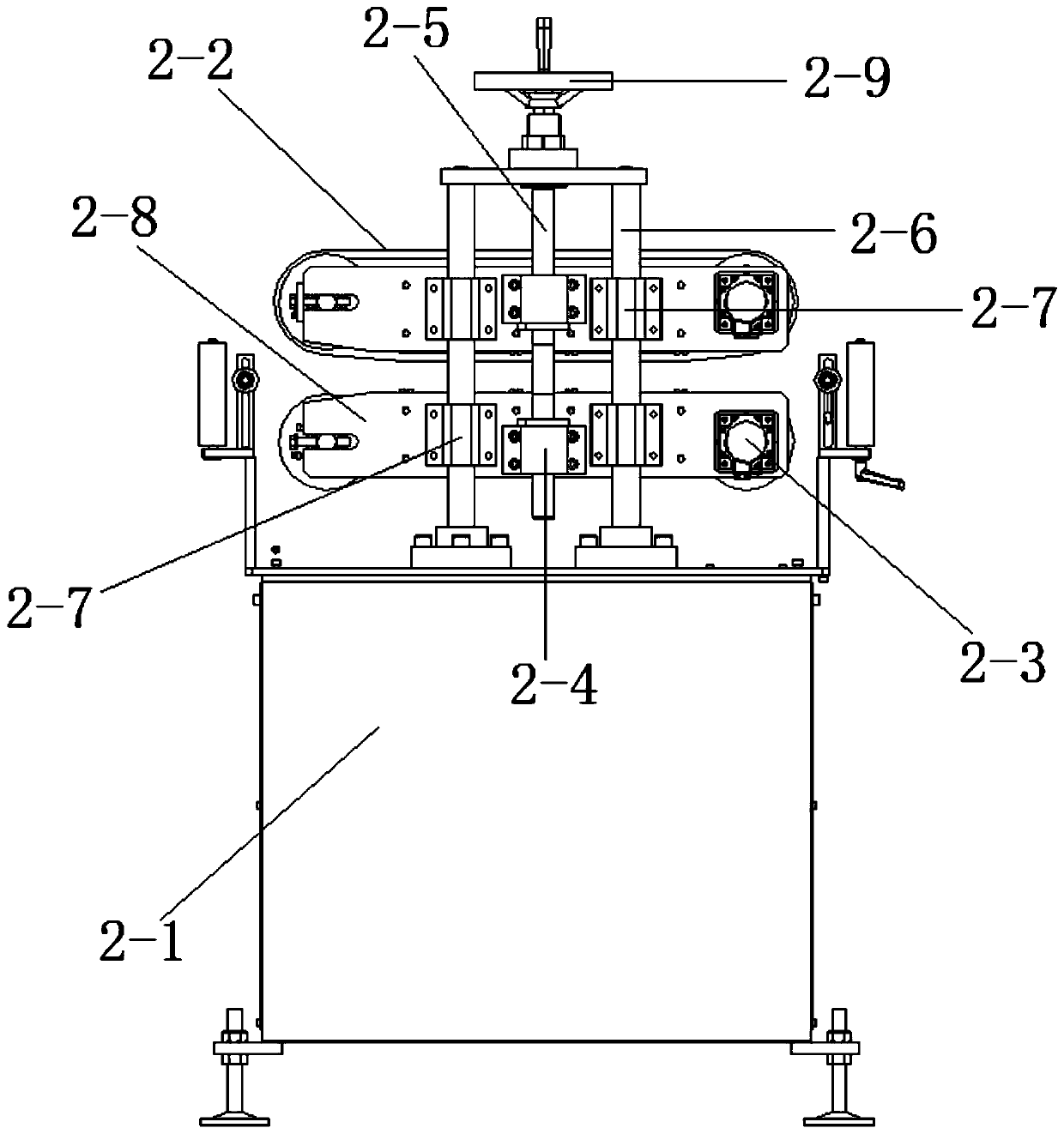

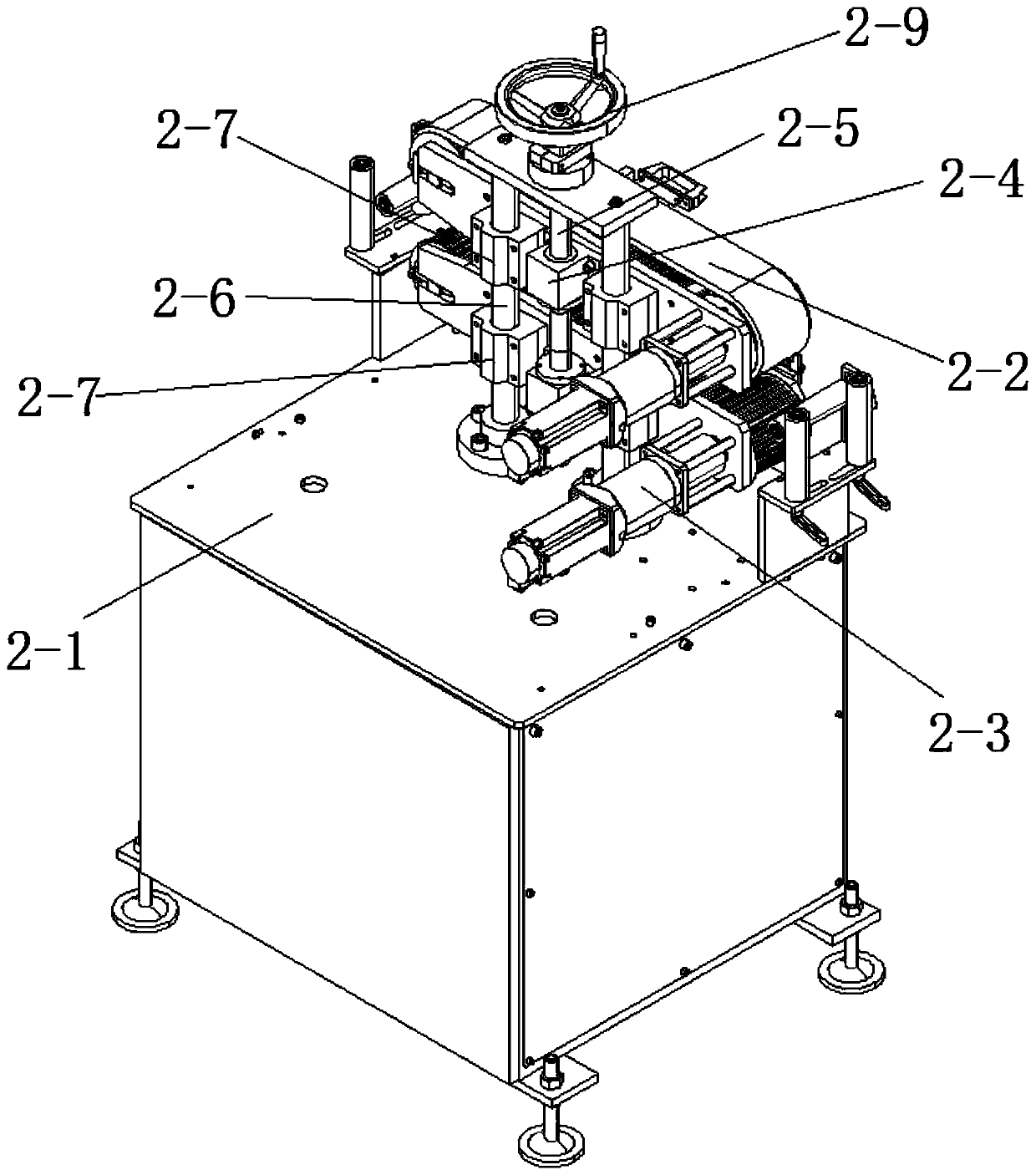

[0031] 1 is the core release machine, 2 is the front traction machine, 3 is the composite extruder, 4 is the outer diameter detector, 5 is the fluoroplastic extruder, 6 is the air cooling device, 7 is the wrapping extruder, 8 is the cooling Groove, 9 is the rear traction machine, 10 is the isolation coating machine, 11 is the hose cutting machine, 12 is the core material, 13 is the inner rubber layer, 14 is the middle rubber layer, 15 is the low permeability layer, 16 is the wrapping layer, 2 -1 frame, 2-2 is the conveyor belt mechanism, 2-3 is the servo motor of the traction machine, 2-4 is the nut, 2-5 is the double...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com