A pvc-gel artificial muscle integrated printing method

A technology of artificial muscle and polyvinyl chloride, which is applied in the field of 3D printing to ensure rigidity, realize rapid prototyping, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

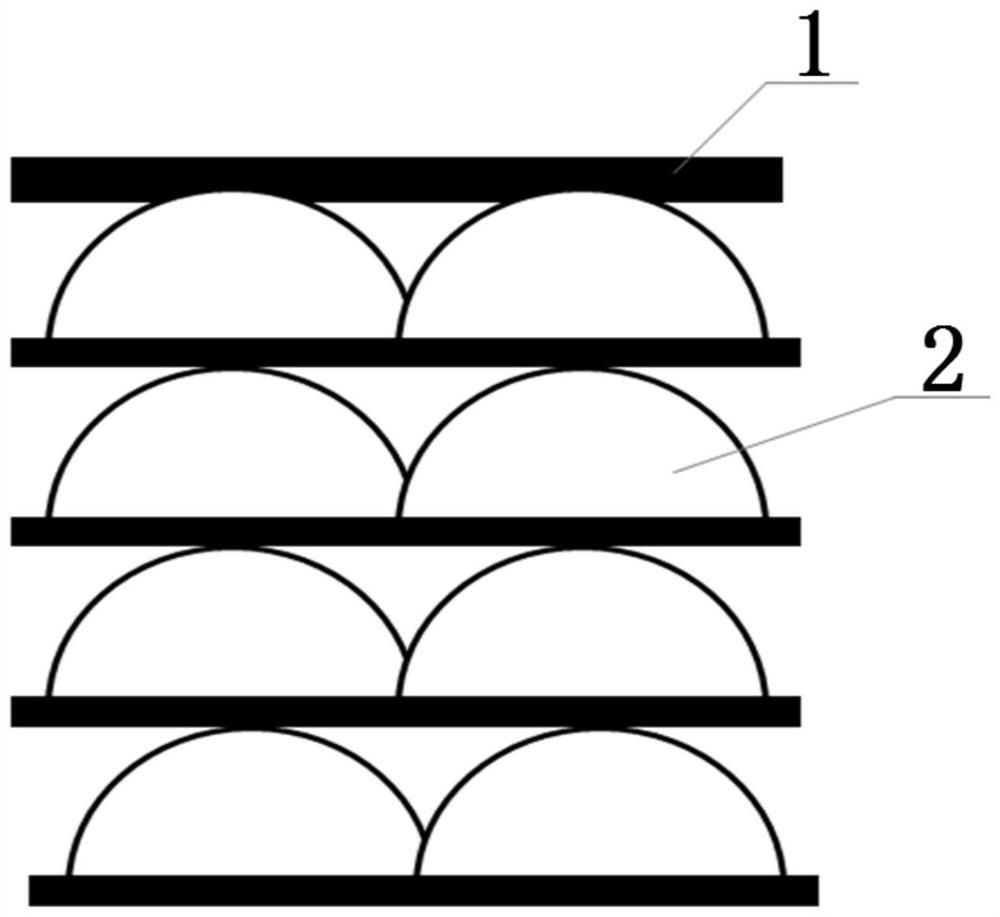

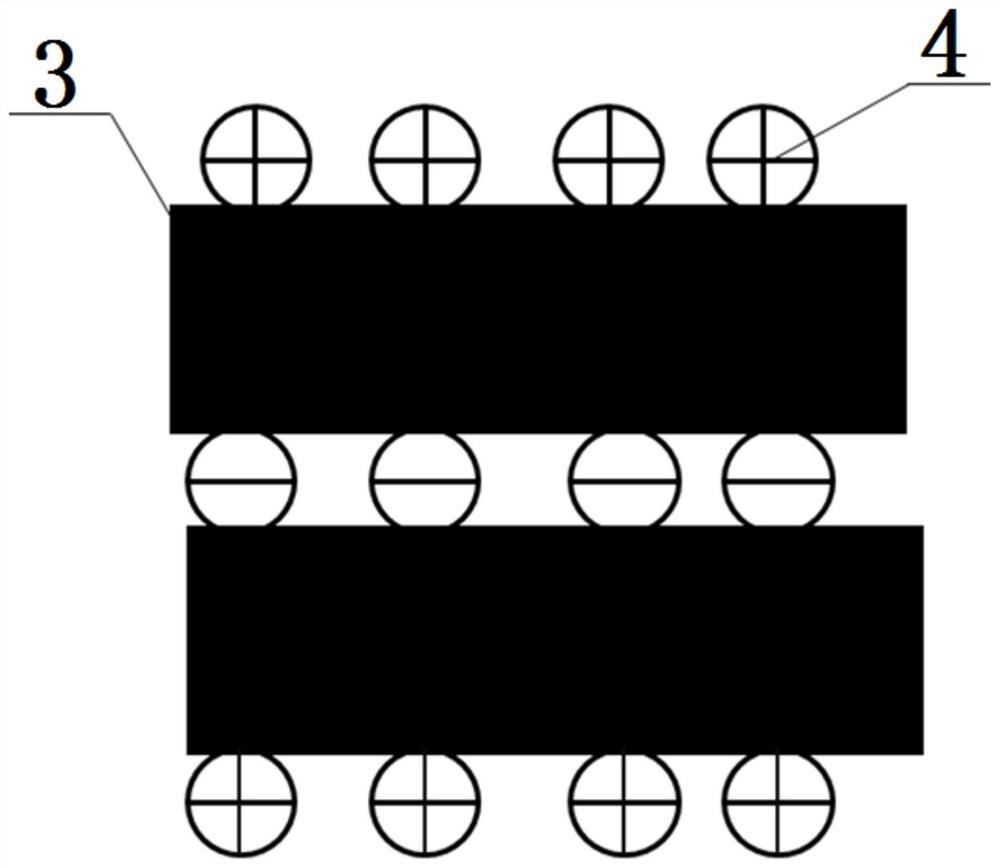

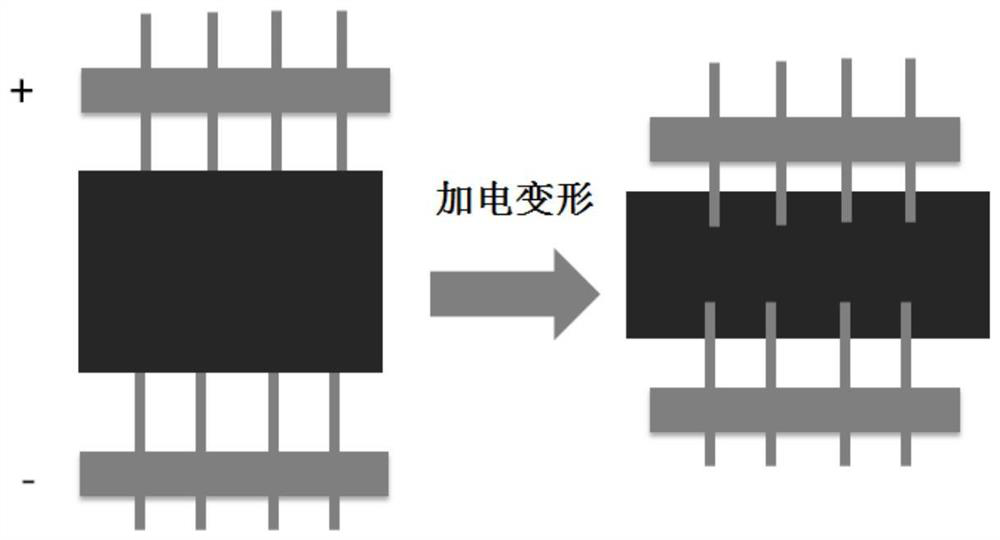

Method used

Image

Examples

Embodiment

[0059] 1) Configuration of PVC core layer printing ink:

[0060] Weigh 2g of PVC-gel powder and 22g of butylene adipate and mix, then add 48g of THF, stir with magnetic force for 2 days until the PVC powder is fully dissolved in THF, DBA and PVC are completely mixed to a colorless transparent liquid, test the solution Its rheological properties and shear thinning properties ensure that the ink density is suitable for direct writing printing.

[0061] 2) Configuration of electrode printing ink

[0062] 1) Weigh 0.35g carbon nanotubes (model TSW3, diameter 10-20nm, length 0.5-2um), mix with 50g isopropanol, ultrasonically disperse for 2h, then add 4.23g PDMS-A component, and ultrasonically disperse for 2h , Magnetic stirring and heating to volatilize isopropanol until the volatilization of isopropanol is complete, then add 0.423g PDMS-B component, and stir evenly into a black viscous slurry.

[0063] 3) Integrated direct writing printing process

[0064] ①Put the PVC ink of the core lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com