Intelligent scaffold safety monitoring method

A safety monitoring and construction frame technology, which is applied in the direction of measuring devices, instruments, and services based on specific environments, etc., can solve the problems of construction personnel casualties, construction frame collapse, dumping, etc., and achieve the prevention of casualties and the accuracy of danger detection High and fast data analysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

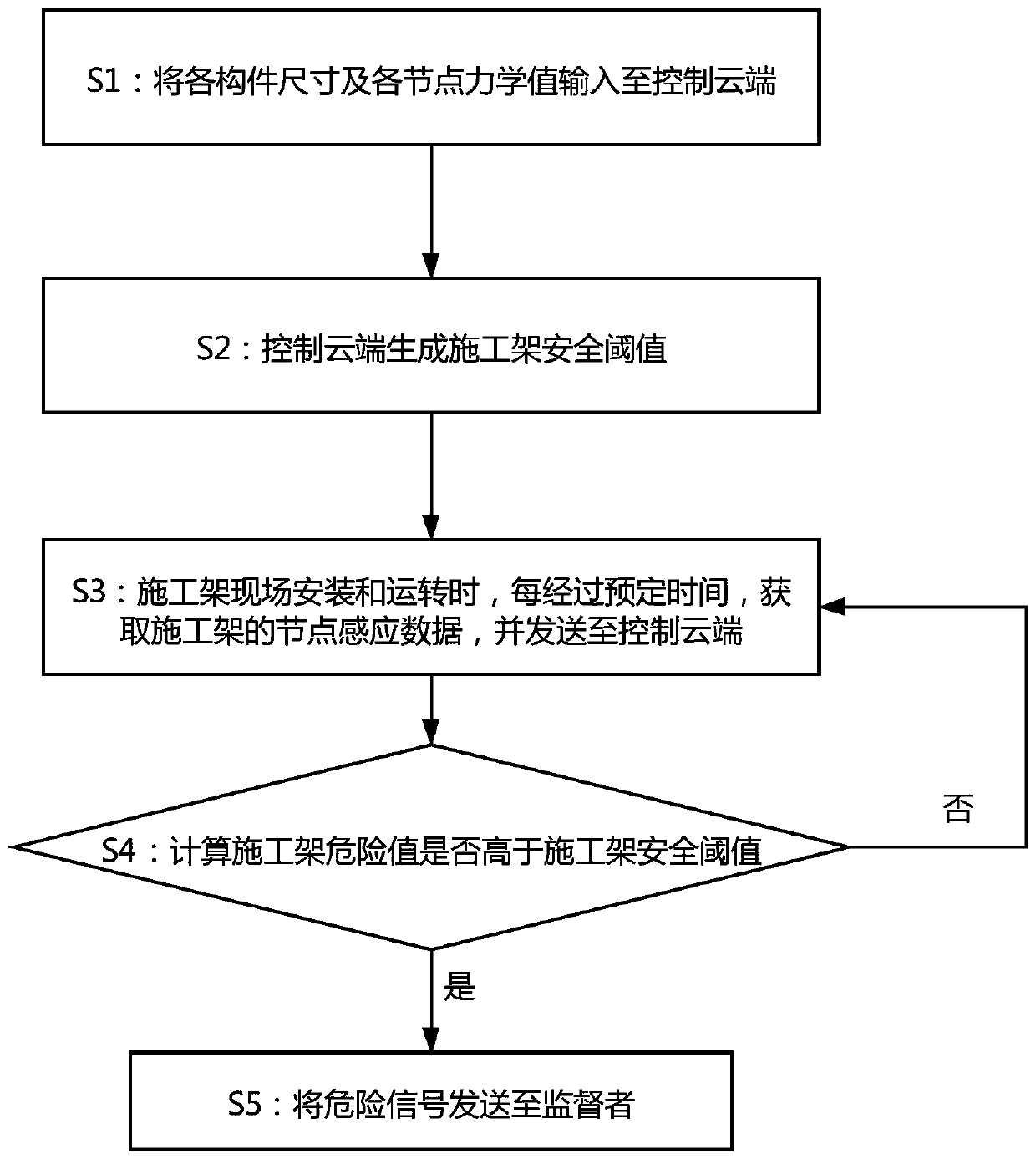

[0029] Embodiment one, such as figure 1 As shown, it is only one of the embodiments of the present invention, a method of intelligent construction frame safety monitoring, comprising the following steps:

[0030] S1: Input the size of each component and the mechanical value of each node to the control cloud;

[0031] Set up stress, strain, GPS, subsidence, tilt and other sensing wireless modules on the joints or structures of the construction frame. The dimensions of each component and the mechanical values of each node are input to the control cloud for real-time detection of the construction frame. Every 1~ Set up a group at 50m, and these sensing functions can be concentrated into a single module or dispersed.

[0032] The sensing wireless module is wirelessly connected to the control cloud, and the wireless network technology uses methods such as Zigbee, WirelessHART, ISA100.11a, Wi-Fi, Bluetooth, etc. to transmit various sensing information to the cloud system for calc...

Embodiment 2

[0042] Embodiment two, still as figure 1 As shown, it is still one of the embodiments of the present invention. In order to make a kind of intelligent construction frame safety monitoring method of the present invention more practical and stable, and the monitoring effect is good, the present invention also has the following designs:

[0043] First, before step S1 is executed, the cloud is controlled to establish a storage database for storing information on the dimensions of each component and the mechanical value of each node.

[0044] Of course, after step S1 is executed, the structural strength of the construction frame is sent to the storage database for calculation and confirmation.

[0045] In addition, when step S2 is executed, the calculation method for generating the safety threshold of the construction frame is a square function closed model algorithm.

[0046] In fact, the calculation method for generating the safety threshold of the construction frame can be calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com