Electromechanical equipment digital twin model consistency maintaining method

A consistent and digital technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems that cannot reflect the performance of physical electromechanical equipment and cannot be implemented, and achieve the effect of accurate model support and guaranteed applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

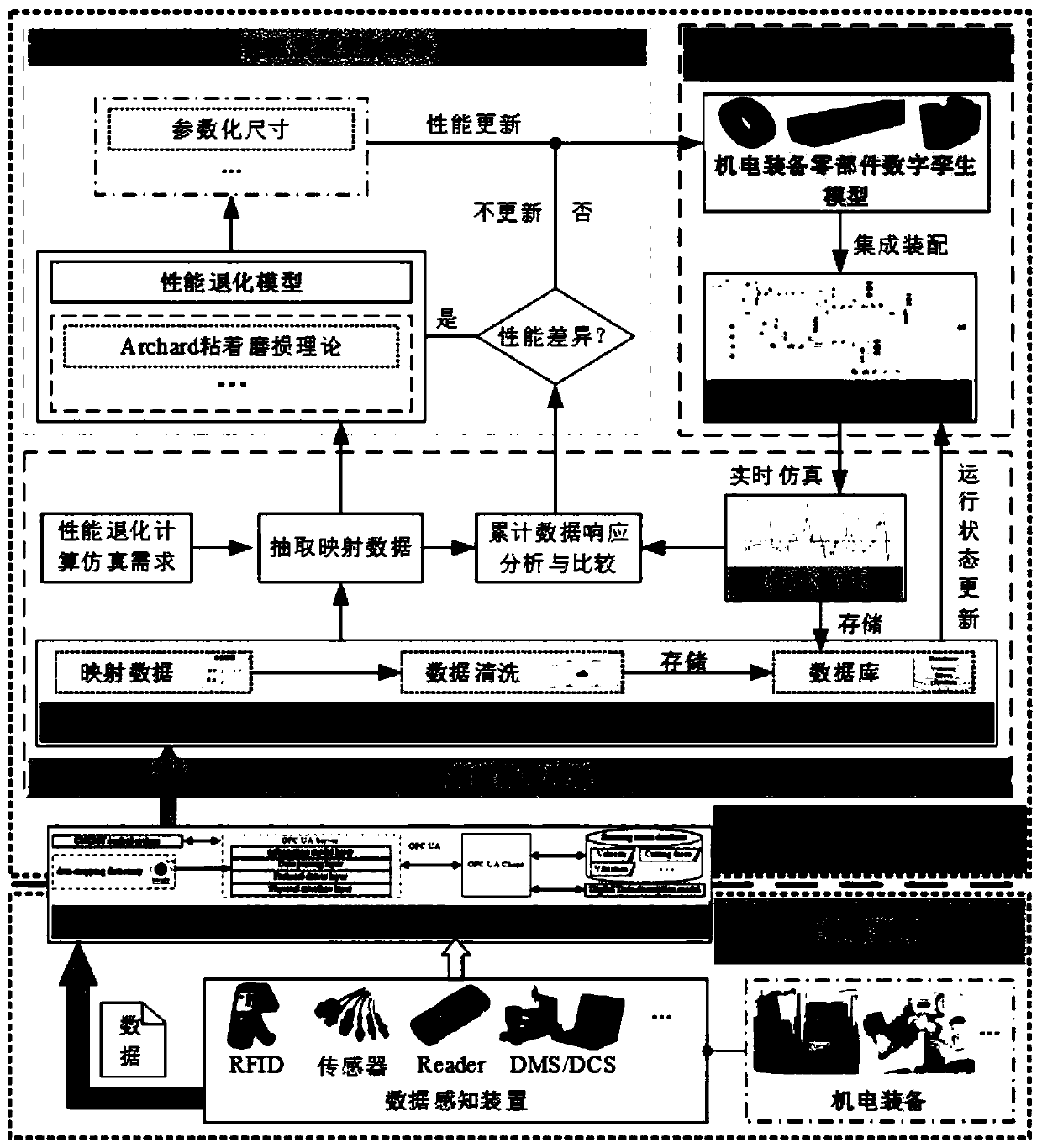

[0026] Such as figure 1 As shown, this embodiment provides a method for maintaining the consistency of the digital twin model of electromechanical equipment, which is applied to the consistency of the digital twin model between the digital space and the physical space. The electromechanical equipment data collected by the data sensing device in the space is mapped to the digital space (a digital twin modeling method for CNC machine tools, which is described in detail in the application number 201711434013X), and then through the data processing module, performance attenuation update module, The self-updating digital twin overall building block gets the updated digital twin.

[0027] Data sensing devices include sensors, controllers, electronic tags, etc. It is used to collect relevant data information of hardware devices in physical space, and then map relevant data information to digital space through the mapping module.

[0028] The data processing module includes data mai...

Embodiment 2

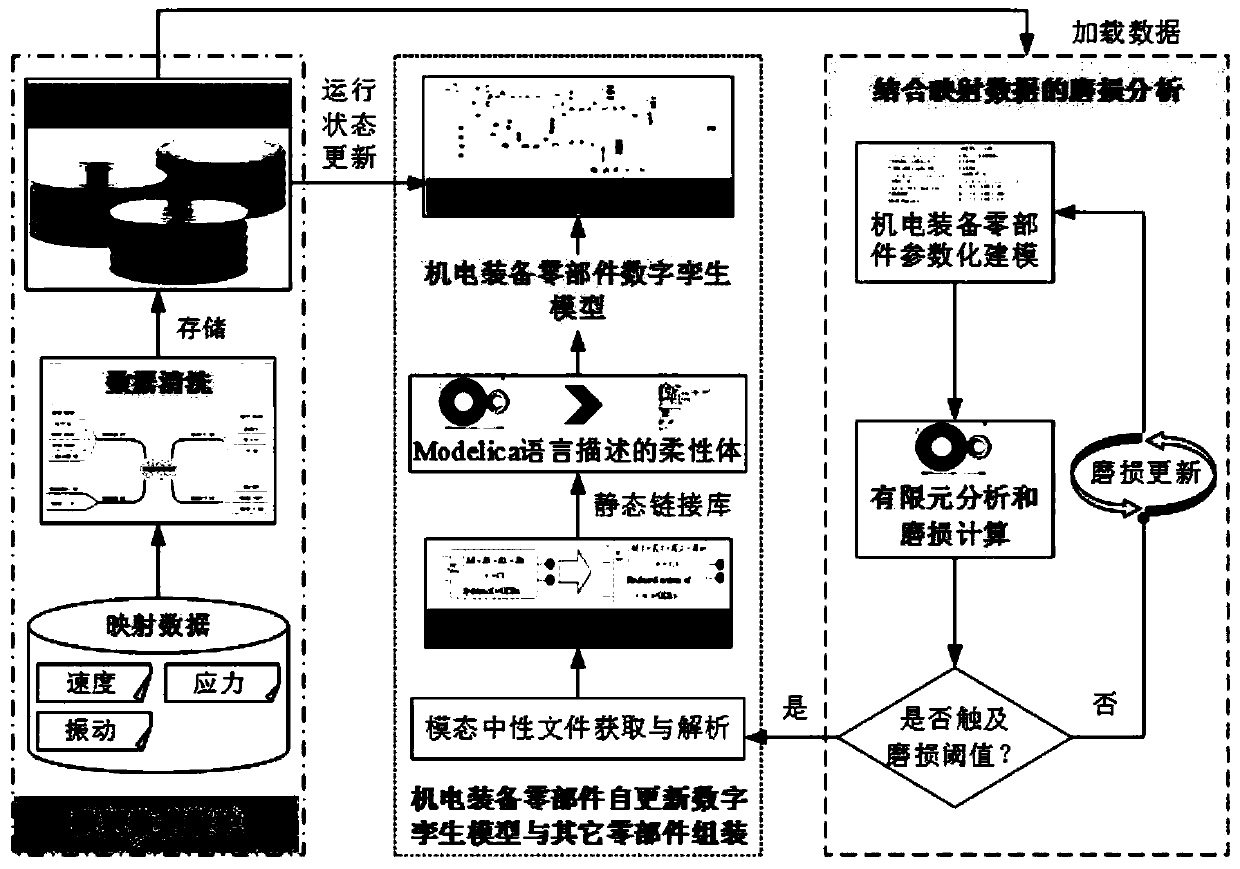

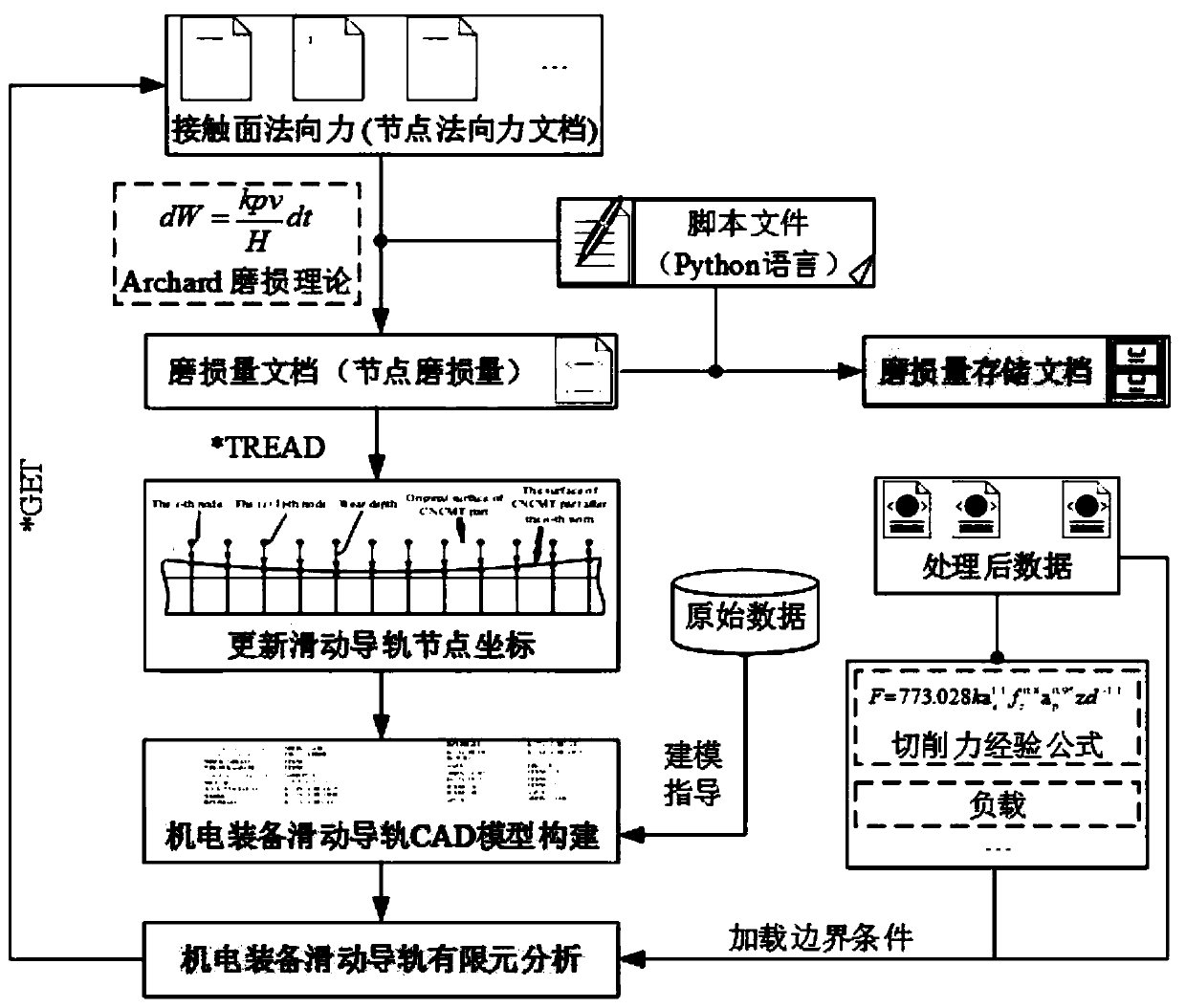

[0033] Such as figure 2 with image 3 As shown, using the technical solution provided in Example 1, the implementation process of model self-update is described by taking the wear update of a sliding guide rail of electromechanical equipment as an example:

[0034] First, use the Ansys parametric design language APDL to establish a parametric CAD model of the guide rail, use the mapping data as boundary conditions to conduct finite element wear analysis on the model, extract the normal stress of the contact surface of many nodes, and use the Archard wear theory Calculate the wear amount of the nodes, read the wear amount of the nodes into the simulation environment through the *VREAD command, and update the nodes of the parameterized sliding guideway model to complete a wear update, perform a modal analysis on the updated sliding guideway, and obtain the MNF( Modal neutral file), write a modal neutral file to analyze the static link library, import the modal information of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com