Method for acquiring the multi-surface three-dimensional shape of moving abrasive particles

A technology of three-dimensional topography and acquisition method, applied in image data processing, instrumentation, 3D modeling, etc., can solve the problems of complex operation, limited use range, different

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Below in conjunction with accompanying drawing, the present invention will be further described.

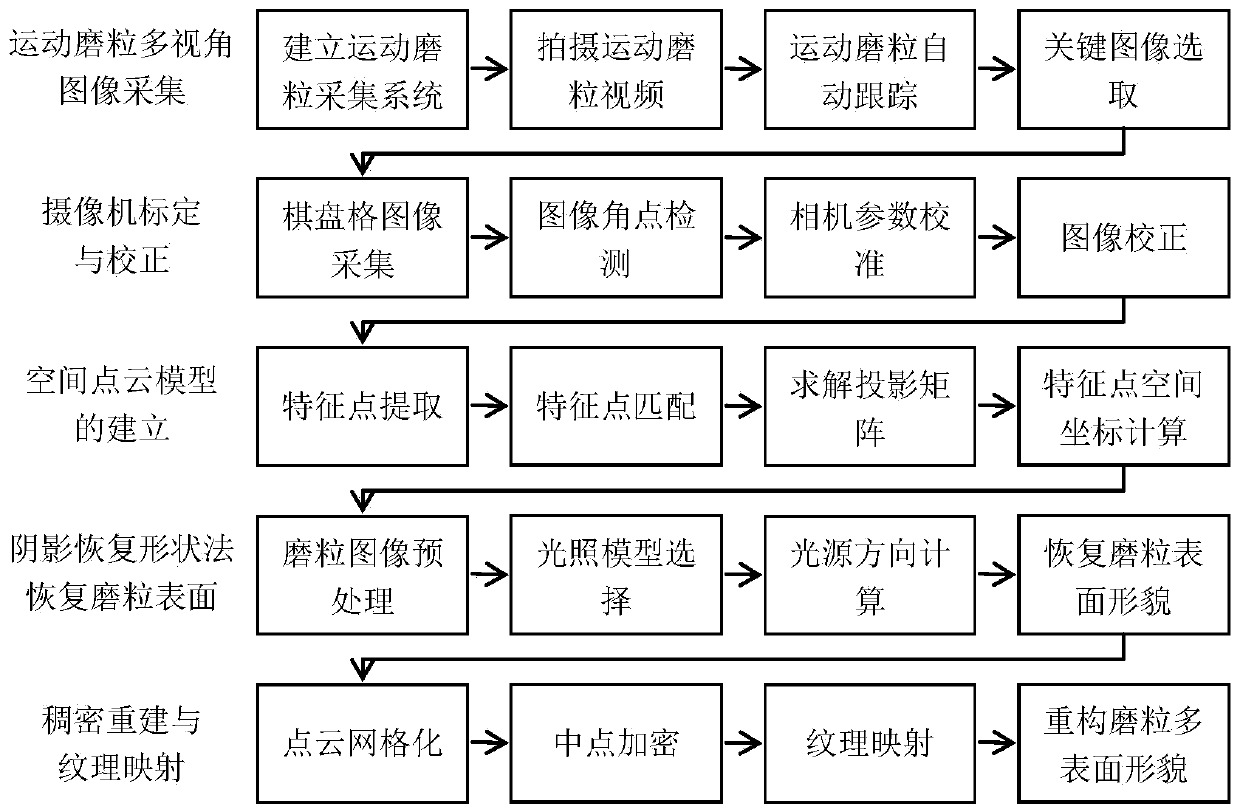

[0084] refer to figure 1 , a method for obtaining three-dimensional topography of multiple surfaces of moving abrasive particles, comprising the following steps:

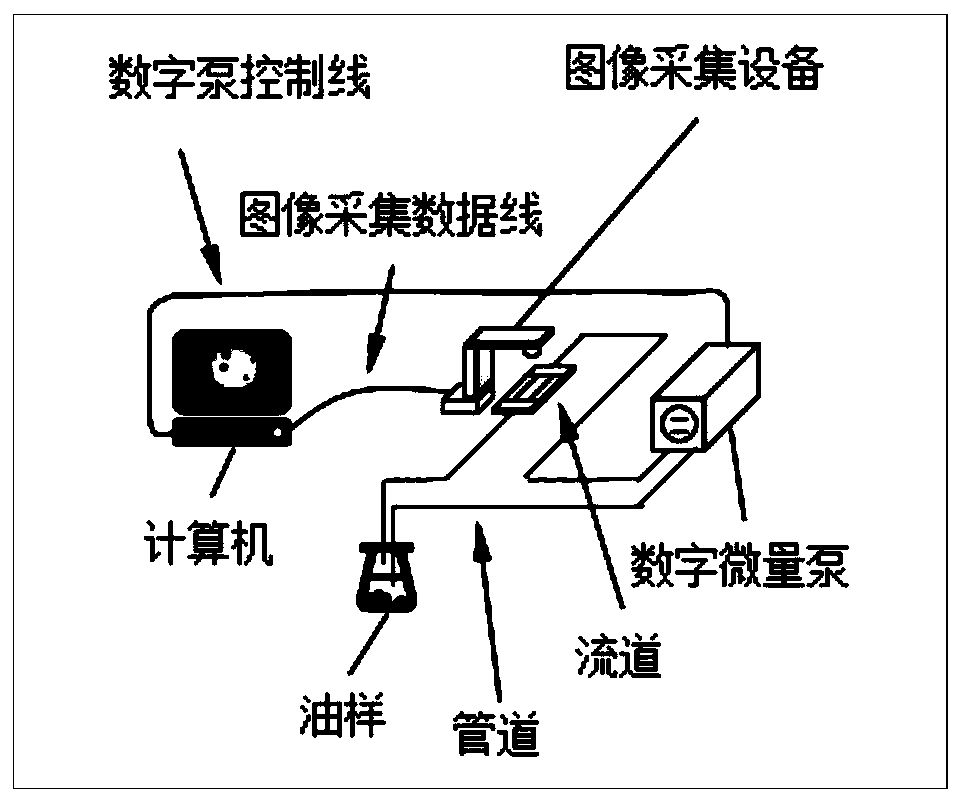

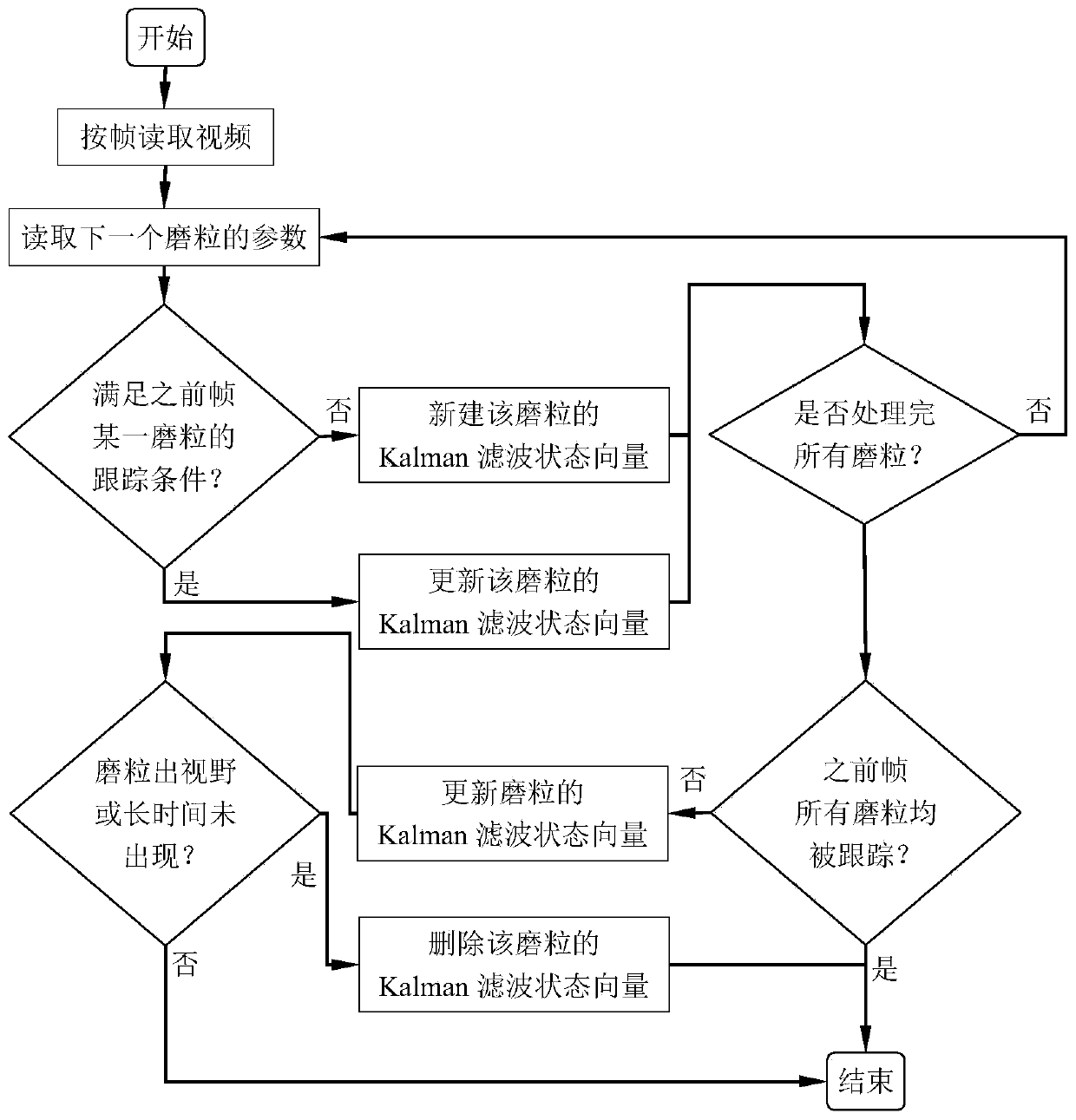

[0085] Step 1: The first step to obtain the three-dimensional shape of the multi-surface of moving abrasive particles is to collect multi-view images of moving abrasive particles. Through the multi-view video acquisition platform of moving abrasive particles, the abrasive particles move and roll in the special flow channel, and the image acquisition equipment collects the abrasive particles. Then the Kalman filter method is used to realize the automatic tracking of the wear particles, and the multi-view image sequence of the target wear particles is selected based on the key frame extraction model.

[0086] The step 1 includes the following specific steps:

[0087] Step 1.1: Establish a multi-view video acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com