Micro LED transfer method

A transfer method and LED structure technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as difficulty in absorbing successfully, and achieve the effect of improving the transfer success rate and improving the problem of membrane breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] This embodiment is a transfer method of micro-LEDs, such as Figure 1 to Figure 12 shown.

[0045] The transfer method includes at least the following steps:

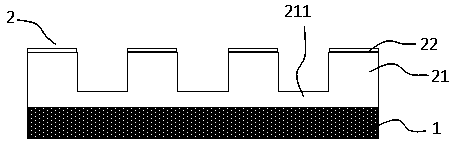

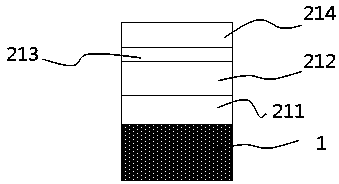

[0046] S1, such as figure 1 As shown, an epitaxial structure is formed on a substrate 1, and after etching (preferably half etching) the epitaxial structure, an array of LED structures 2 is formed on the substrate 1, figure 2 Shown is a partial structural schematic diagram of each LED structure 2 .

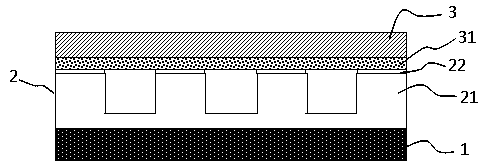

[0047] S2, such as image 3 As shown, after the LED structure 2 in step S1 is transferred to the first transient substrate 3, as Figure 4 As shown, peel off the substrate 1, as Figure 5 As shown, the LED structure 2 and the first transient substrate 3 are turned over together, so that the LED structure 2 is on the top and the first transient substrate 3 is on the bottom.

[0048] S3, such as Image 6 As shown, the LED structure 2 in step S2 is etched again and a plurality of separated LEDs 4 are formed, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com