A crop straw removal mechanism and removal method thereof

A crop straw and frame technology, which is applied in the field of crop straw removal mechanism and its removal, can solve the problems of small resilience of green straw and thin straw, missing and broken straw, and inability to apply sufficient friction to crop straw, etc. Achieve the effect of large contact area and long contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

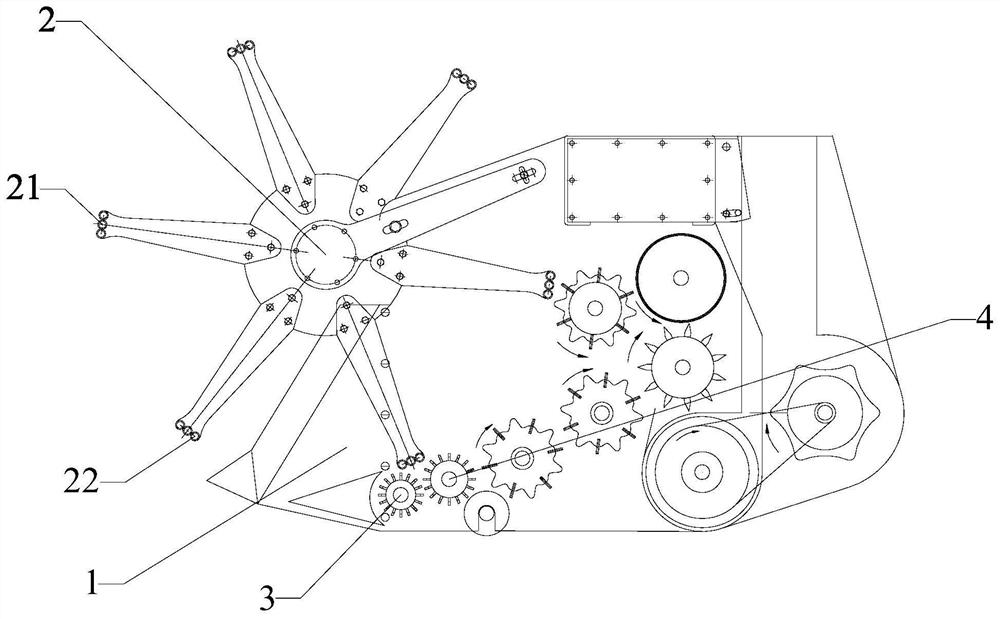

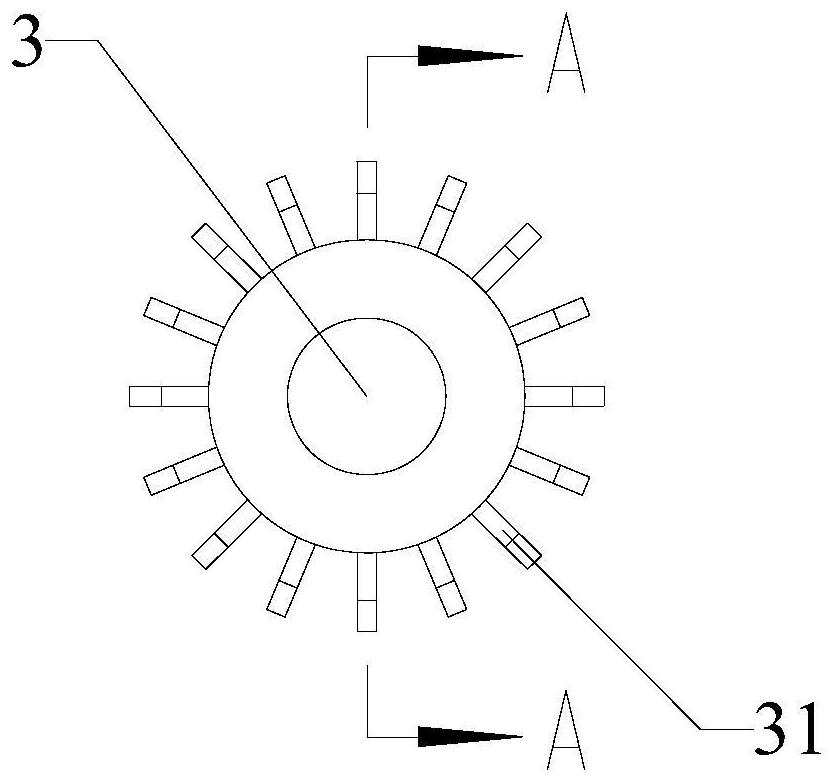

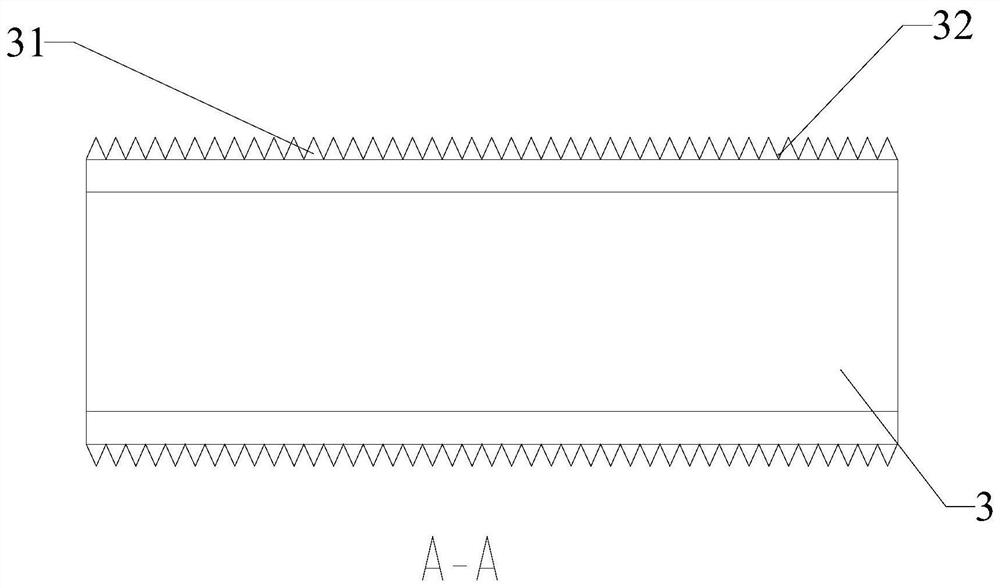

[0043] A crop straw plucking mechanism, comprising a stalk plucking rotor 2 and a first stalk plucking rotor 3 arranged on a frame 1, the stalk plucking rotor 2 and the first stalk plucking rotor 3 have opposite directions; the stalk plucking rotor 2 The rotation axis of the first stalk pulling rotor 3 is set at the front and upper part of the first stalk pulling rotor 3 relative to the frame 1; the outer edge of the first stalk pulling rotor 3 is provided with a plurality of stalk pulling racks 31, so The depth of the tooth root of the stalk pulling rack 31 is less than twice the diameter of the crop straw; diameter of.

[0044] The outer periphery of the stalk-pulling rotor 2 is provided with a plurality of stalk-pulling grid bars 21 . The number of the stalk pulling racks 31 is more than 10, the tooth crests between two adjacent stalk pulling racks 31 are arranged in a staggered manner, and the spacing between adjacent racks is less than 35 mm. The tooth included angle 32...

Embodiment 2

[0046] A crop straw pulling mechanism according to Embodiment 1, wherein the outer periphery of the stalk-pulling rotor 2 is provided with a plurality of stalk-pulling grid bars 21, and the stalk-pulling grid bars 21 include one stalk-pulling roller arranged side by side. 22. The centers of the stalk-pulling rollers 22 are distributed on the same circumference with the rotation axis of the stalk-pulling rotor 2 as the center of the circle.

Embodiment 3

[0048] A crop straw pulling mechanism according to Embodiment 2, wherein the outer periphery of the stalk-pulling rotor 2 is provided with a plurality of stalk-pulling grid bars 21, and the stalk-pulling grid bars 21 include three stalk-pulling rollers arranged side by side twenty two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com