Multi-arm type harvesting robot and picking method thereof

A robot and arm-type technology, applied in the direction of picking machines, harvesters, manipulators, etc., can solve the problems of low work efficiency and achieve the effect of improving work efficiency and shortening the picking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

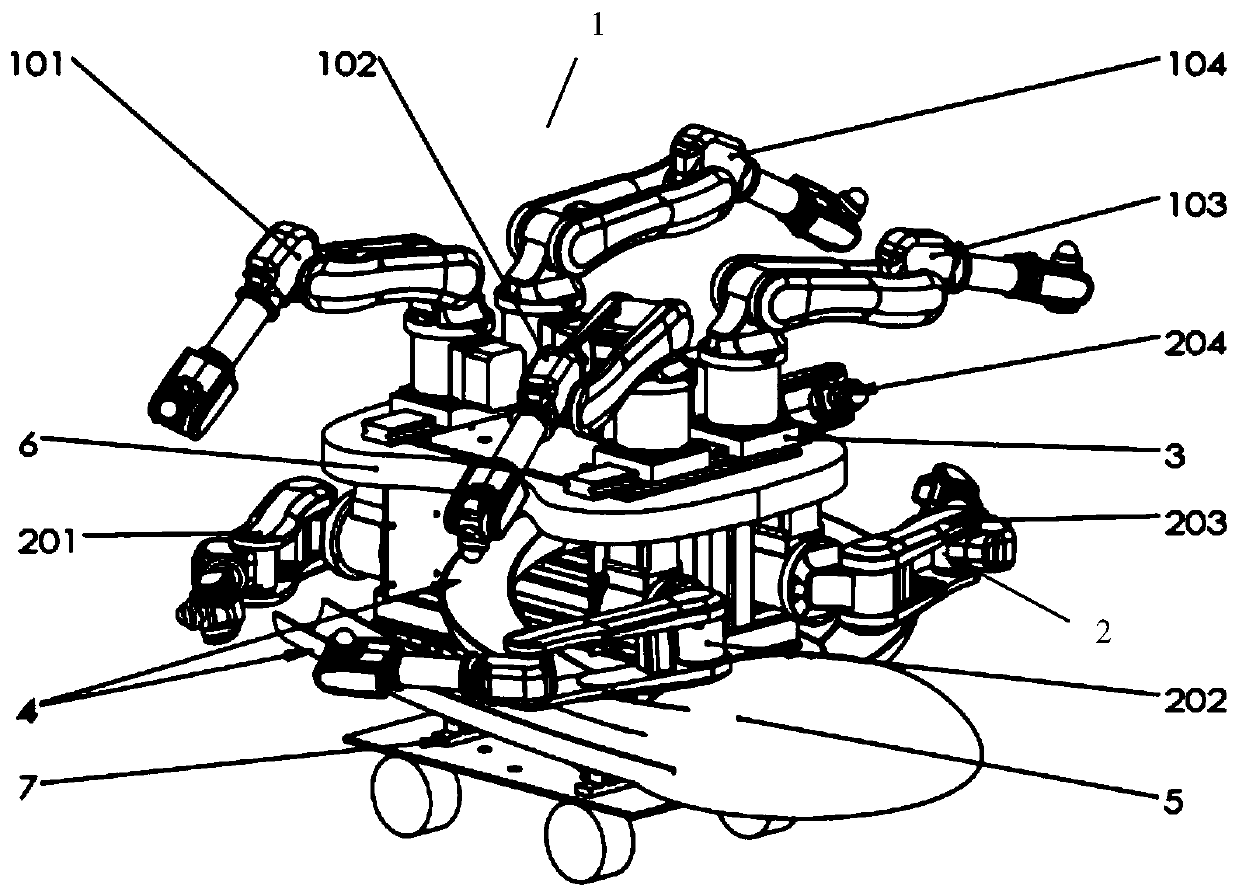

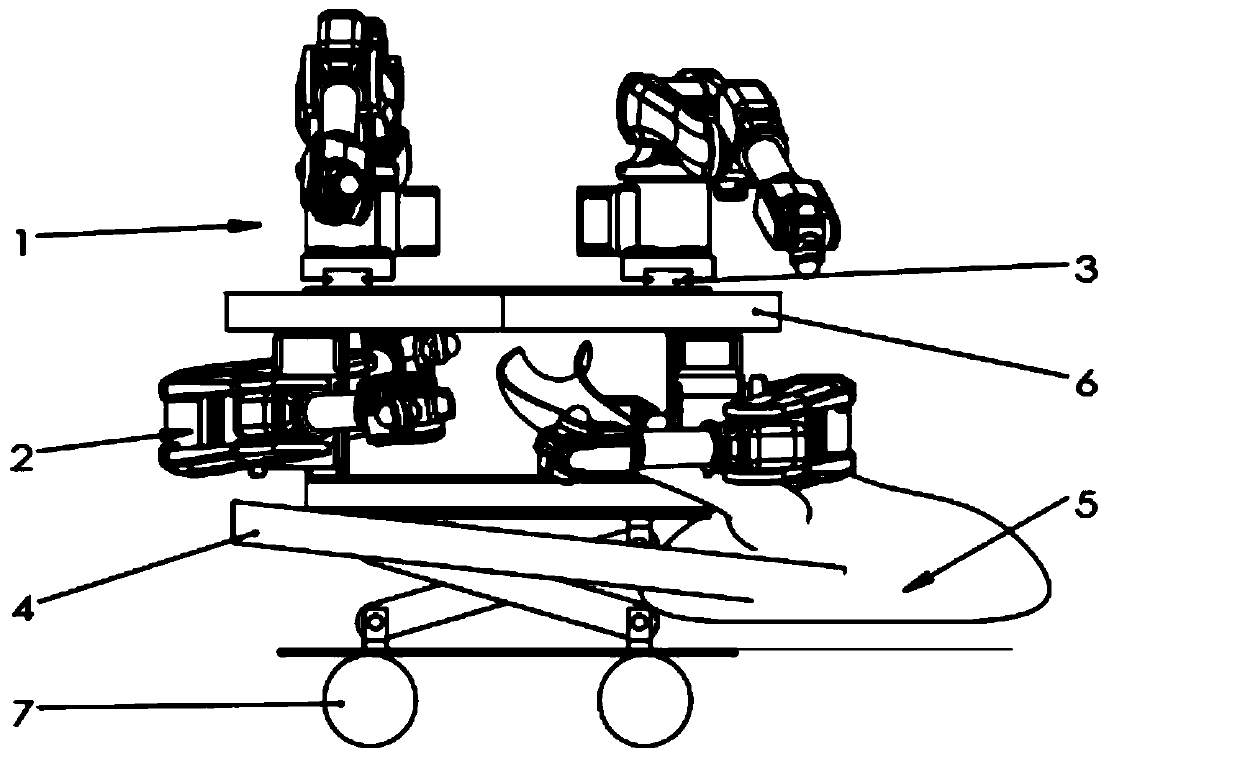

[0025] Such as Figure 1 to Figure 2 As shown, a multi-arm type harvesting robot includes a picking robot arm system and a chassis system 7, and the picking robot arm system includes a picking robot arm group, a working platform 6, and a fruit storage device, and the picking robot arm group includes An upper-layer picking robot arm group 1 and a lower-layer picking robot arm group 2 each provided with four robotic arms, a guide rail slider mechanism 3 is installed on the working platform 6, and an upper-layer picking robot arm group 1 is carried. The fruit storage device is installed at the lower end of the picking robot arm group, and includes a connected fruit storage device 5 and a fruit collection device 4 . The upper layer picking robot arm group 1 adopts the method of vertical installation; the lower layer picking robot arm group 1 is installed on the side of the working platform 6 and adopts the method of horizontal installation.

[0026] Specifically, there is a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com