Ecological bundle manufacturing and construction method for side slope soil and water conservation

A construction method and ecological technology, applied in the fields of botanical equipment and methods, excavation, application, etc., can solve problems such as large amount of engineering, high cost, complex technology, etc. fast growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

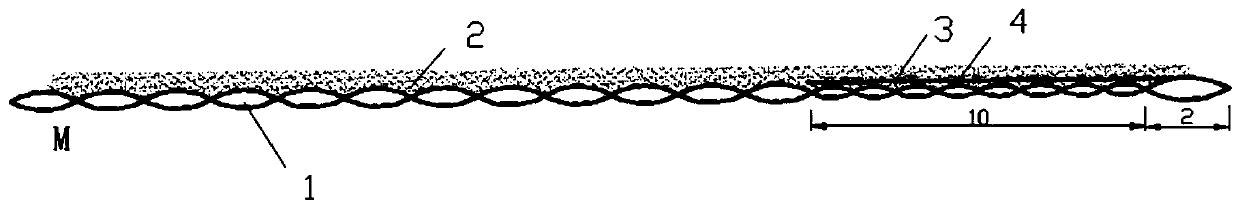

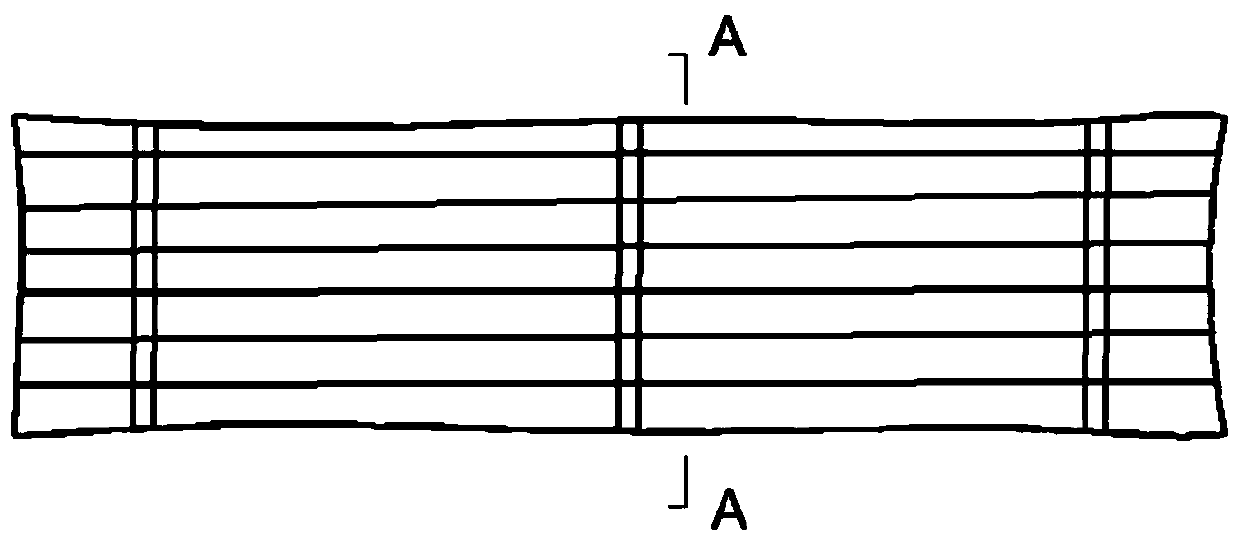

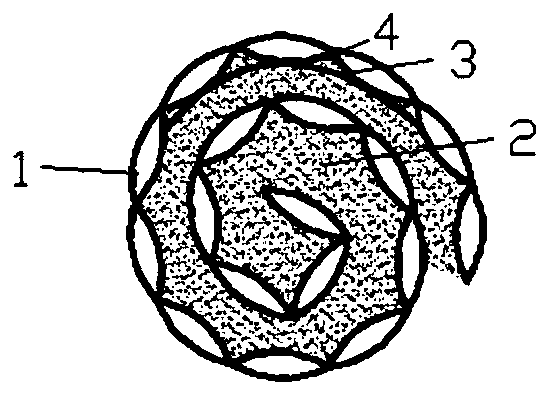

Embodiment 1

[0044] Weigh 3000g, 100g, 30g, 10g, 10g, 20g of slope soil, plant fallen leaf compost, rice straw, rice husk charcoal, quicklime, and water-retaining agent respectively, and stir them fully in a mixer; Spread a sunshade net within 2-12cm from the edge, and spread a 0.5cm thick substrate (about 100g, within the range of 2-12cm from the edge of the straw braid) on it, and evenly sprinkle 5g of vetiver seeds on the substrate; weigh 2kg of mixed Uniform substrate, evenly spread on the whole straw woven fabric (plant growth substrate layer 2). Start rolling from the M end to form a bundle-like roll structure, and tie it tightly with hemp rope (4mm).

Embodiment 2

[0046] Weigh 3000g, 150g, 40g, 15g, 15g, and 30g of slope soil, plant fallen leaf compost, rice straw, rice husk charcoal, quicklime, and water-retaining agent respectively, and stir them fully in a mixer; Spread a sunshade net within 2-12cm from the edge, and spread a 0.5cm thick substrate (about 100g, within the range of 2-12cm from the edge of the straw braid) on it, and evenly sprinkle 5g of vetiver seeds on the substrate; weigh 2kg of mixed Spread evenly on the entire straw braid. Start rolling from the M end to form a bundle-like roll structure, and tie it tightly with hemp rope (4mm).

Embodiment 3

[0048] Weigh the slope soil, plant fallen leaf compost, rice straw, rice husk charcoal, quicklime, and water-retaining agent to be 3000g, 200g, 50g, 20g, 20g, and 40g respectively, and stir them fully in a mixer; Spread a sunshade net within 2-12cm from the edge, and spread a 0.5cm thick substrate (about 100g, within the range of 2-12cm from the edge of the straw braid) on it, and evenly sprinkle 5g of vetiver seeds on the substrate; weigh 2kg of mixed Spread evenly on the entire straw braid. Start rolling from the M end to form a bundle-like roll structure, and tie it tightly with hemp rope (4mm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com