Vacuum suction casting chamber nitrogen charging explosion-proof device

An explosion-proof device and vacuum suction casting technology, which is applied in the field of explosion-proof devices, can solve the problems of personal injury safety accidents, fast gas generation speed, and large gas generation volume of coated sand, etc., and achieve the effect of protecting the personal safety of the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

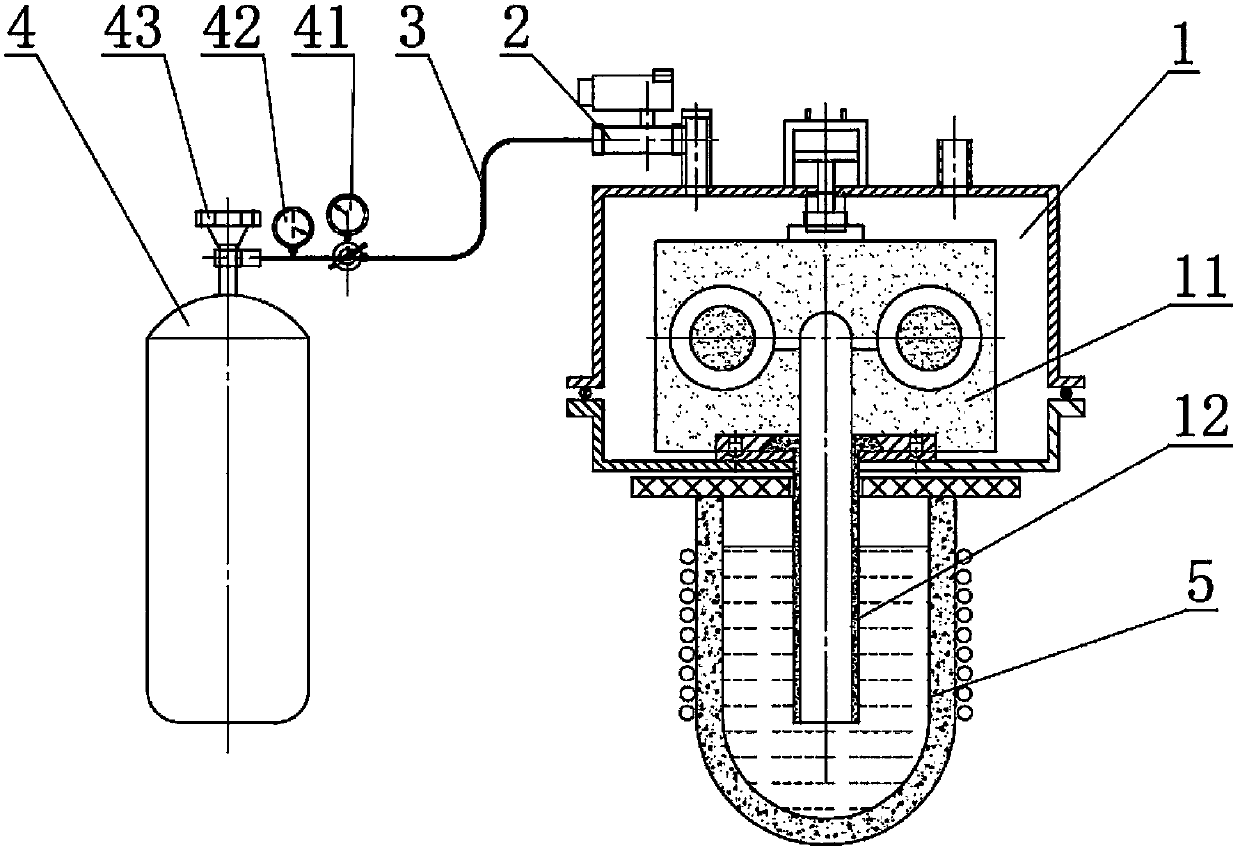

[0016] Such as figure 1 As shown, a nitrogen-filled explosion-proof device for a vacuum casting chamber includes a suction casting chamber (1), an electromagnetic pressure relief valve (2), and a nitrogen tank (4). The shell mold casting chamber (1) is equipped with type (11), ceramic liquid riser (12), the top of which is provided with an electromagnetic pressure relief valve (2), the electromagnetic pressure relief valve (2) is connected to the nitrogen tank (4) through a hose (3), and is directed to the suction The casting chamber (1) is filled with nitrogen to relieve pressure, and the nitrogen tank (4) is equipped with a pressure reducing valve (41), a pressure gauge (42), and a shut-off valve (43) to monitor the equipment status, and the electromagnetic pressure relief valve ( 2) Connect the nitrogen tank (4) through the hose (3), and fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com