Metal sheet paper cutting method

A technology of metal sheets and sheets, applied in the field of metal sheet paper-cut art, can solve problems such as difficult to complete works, tearing of metal sheets, insufficient strength and toughness of metal sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

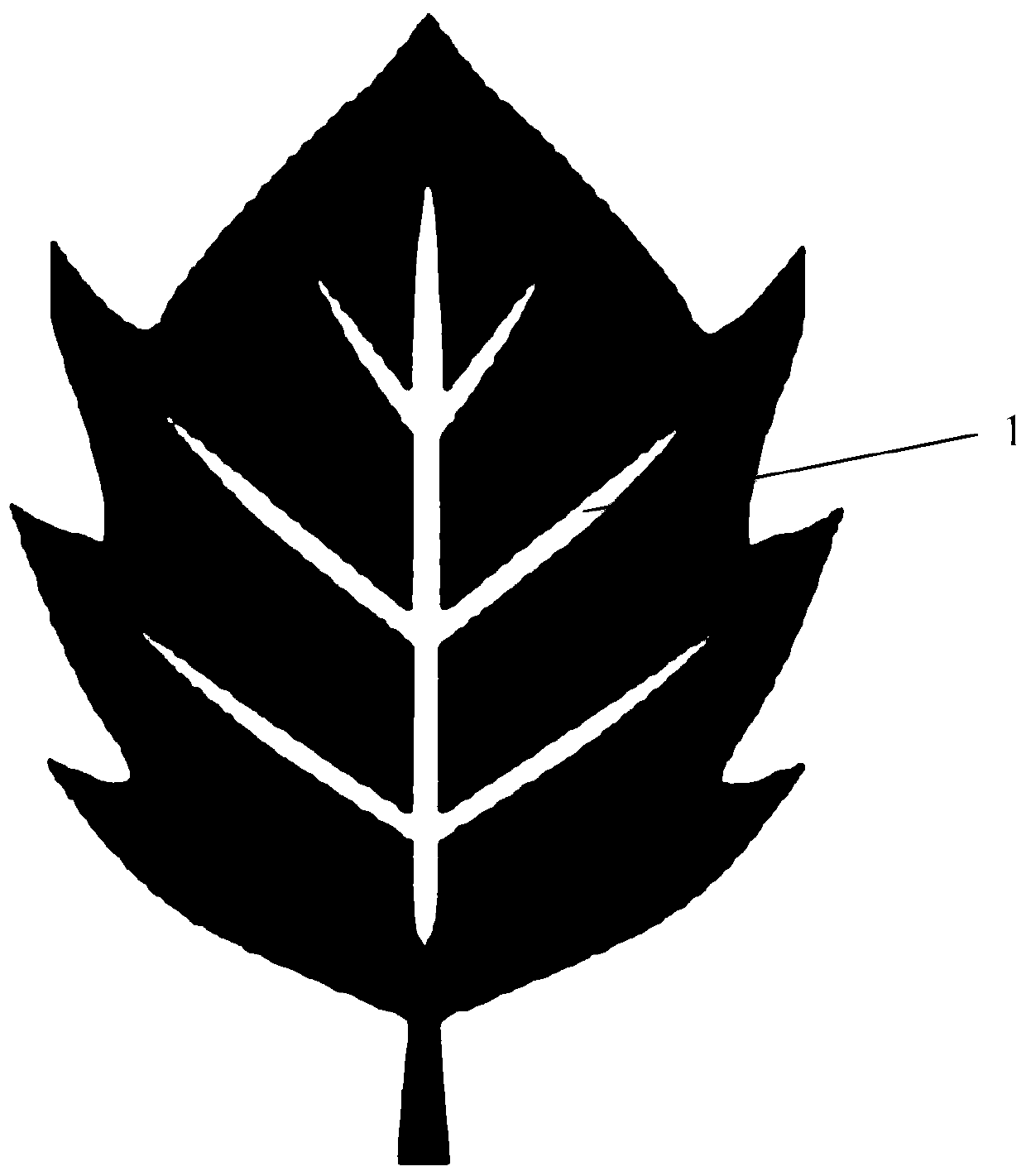

Image

Examples

Embodiment Construction

[0022] The metal sheet is a stainless steel sheet, and the paper-cutting method of the stainless steel sheet includes the following steps:

[0023] 1) Fix the patterned template paper on the stainless steel sheet, and fix the protective paper under the stainless steel sheet at the same time;

[0024] 2) For the hollow pattern on the template paper, use a carving knife to carve a "cross" opening at the lower cut for non-long coniferous hollow patterns, and use a carving knife to carve a "one" opening at the lower cut for long coniferous hollow patterns. The two kinds of openings are all carved through template paper, stainless steel sheet and protective paper on the backing plate;

[0025] 3) Use scissors to cut paper by hand, and cut through the template paper, stainless steel sheet and protective paper at the same time. For the hollow pattern, cut at the pre-engraved "cross" opening or "one word" opening;

[0026] 4) Separate the template paper, arrange the cut stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com