Built-in thread opening processing die and manufacturing process of internal thread high-borosilicate glass cup

A technology for processing molds and thread openings, which is applied to the manufacturing process of built-in thread opening processing molds and internal thread high borosilicate glass cups, and achieves the effects of simple processing operations, accurate processing threads, and easy removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

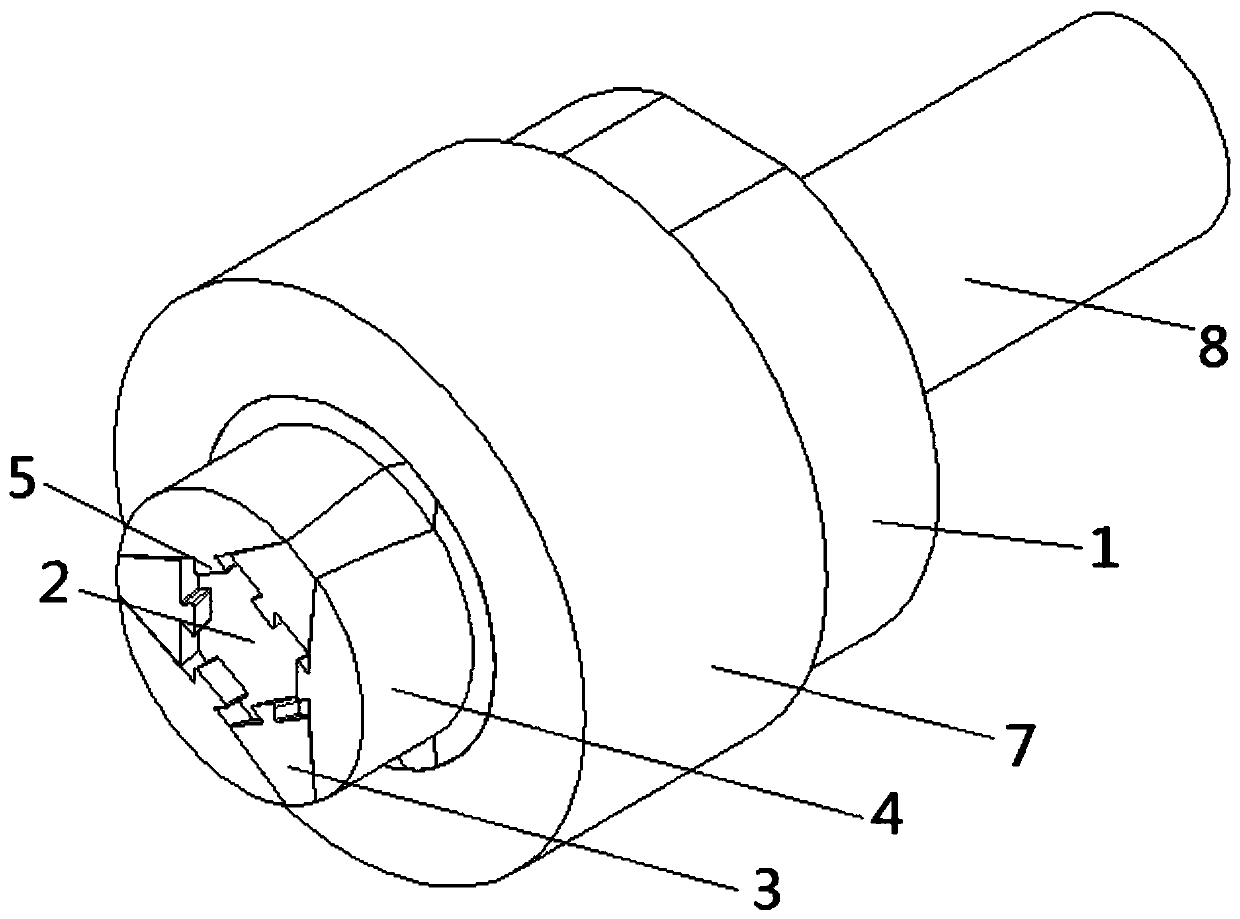

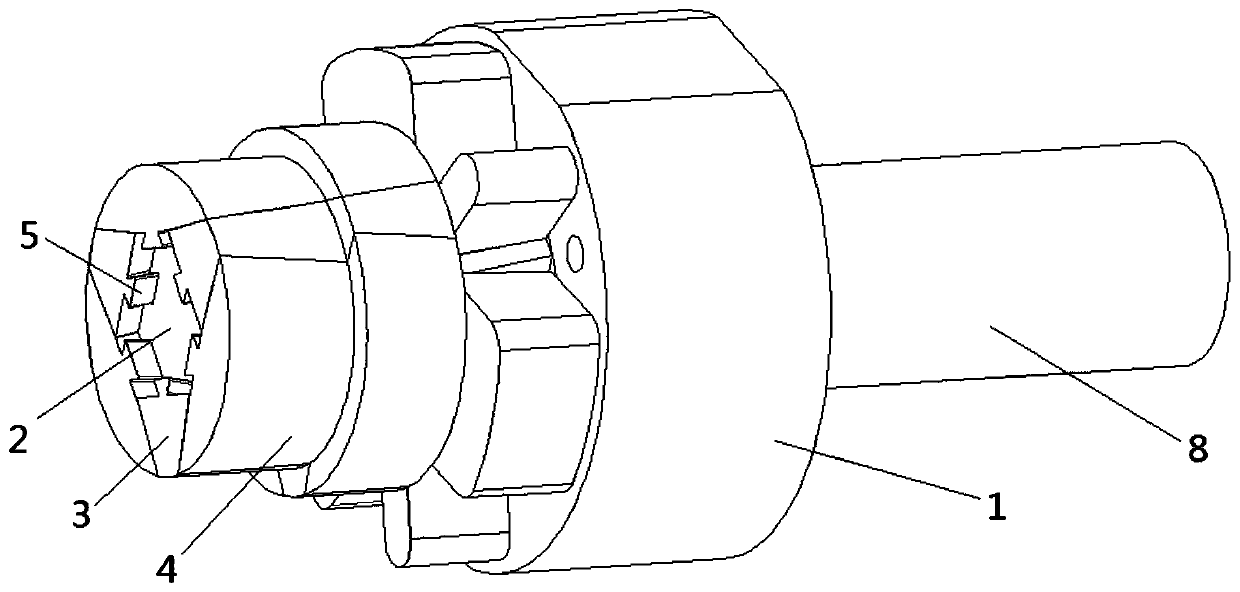

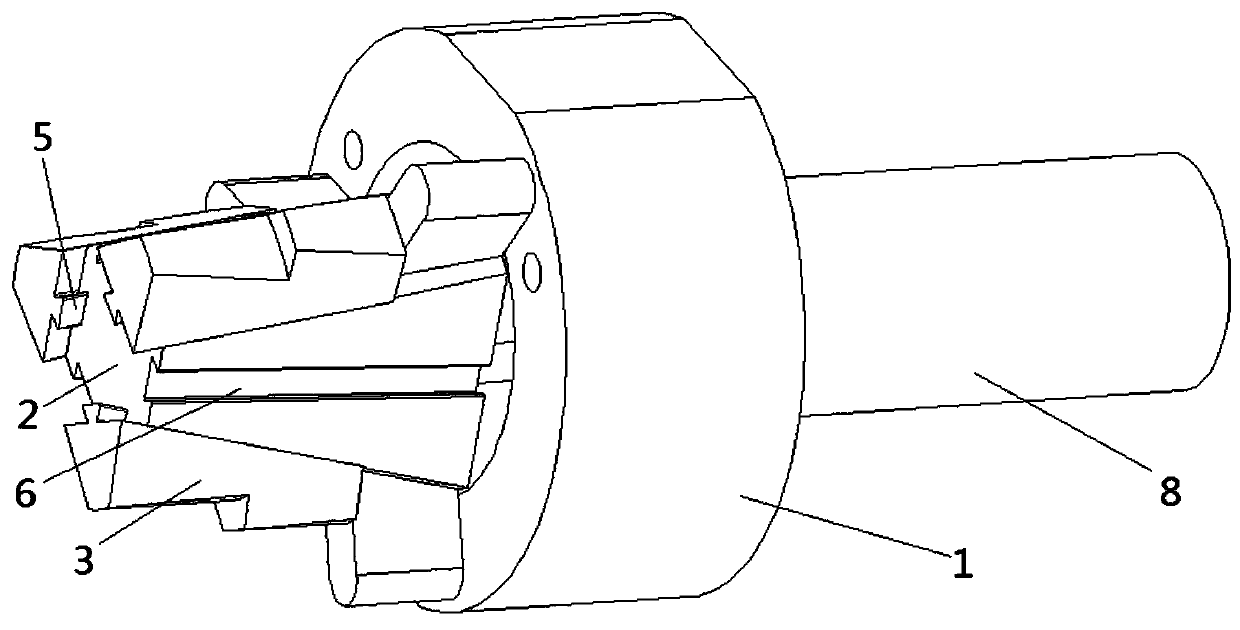

[0031] Please refer to the figure, in the embodiment of the present invention, a built-in screw hole processing mold includes a mounting base 1, a telescopic assembly 2, a first assembly 3 and a second assembly 4; the mounting base 1 is a cylindrical hollow structure, One side of the seat 1 is coaxial with a hollow shaft 8, the hollow shaft 8 communicates with the installation seat 1, the installation seat 1 and the hollow shaft 8 are integrated, and the drive unit is connected to the hollow shaft 8 to drive the entire processing mold to rotate; A telescopic assembly 2 is coaxially arranged in the mounting seat 1 to move upwards in the axial direction. The outer port of the telescopic assembly 2 is larger than the inner port. Six slopes are arranged on the side wall of the telescopic assembly 2, which are alternately distributed The first slope 10 and the second slope 11, the first slope 10 is a rectangular surface, and the second slope 11 is a trapezoidal surface; the inner en...

Embodiment 2

[0036] On the basis of Example 1, threaded grooves are provided on the outside of the first component 3 and the second component 4, and the threaded grooves described when the sides of the first component 3 and the second component 4 are butted to form a cylindrical structure The groove connection forms a complete thread, so that the glass tube sleeved on the outside forms a thread after being heated and pressed, and realizes the process of processing the thread on the inner wall of the glass tube.

[0037] In the mold manufacturing process, each component is cut by laser, and the laser source generally uses a carbon dioxide laser beam. The laser beam is concentrated in a small area, the focal point heats up quickly, and the energy is highly concentrated. Only a small amount of locally formed heat is transferred to the steel. other parts, but the heat conduction part is much smaller than the heat input by the laser beam. The stainless steel material is rapidly heated and vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com