Patents

Literature

32results about How to "Implement built-in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

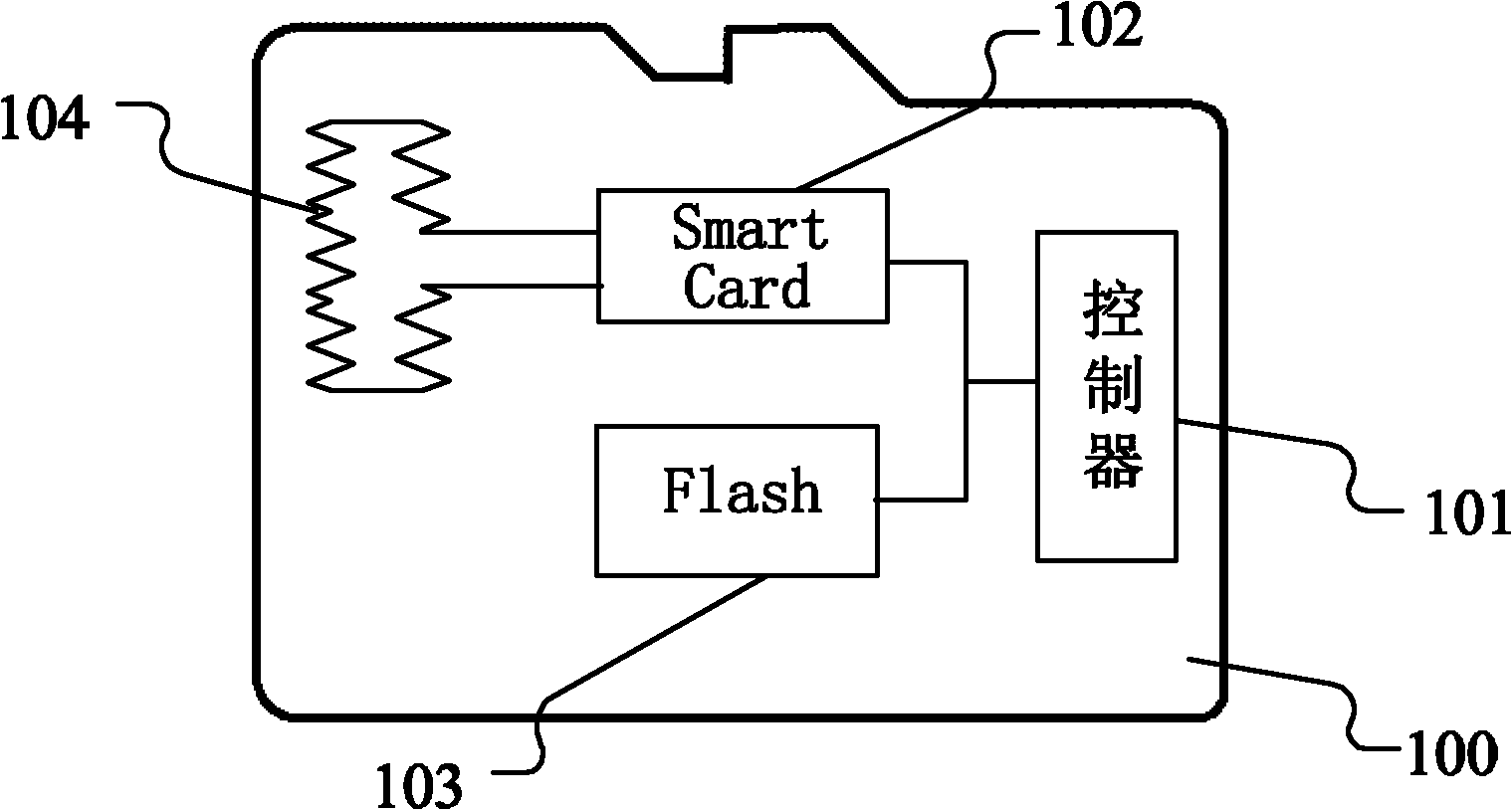

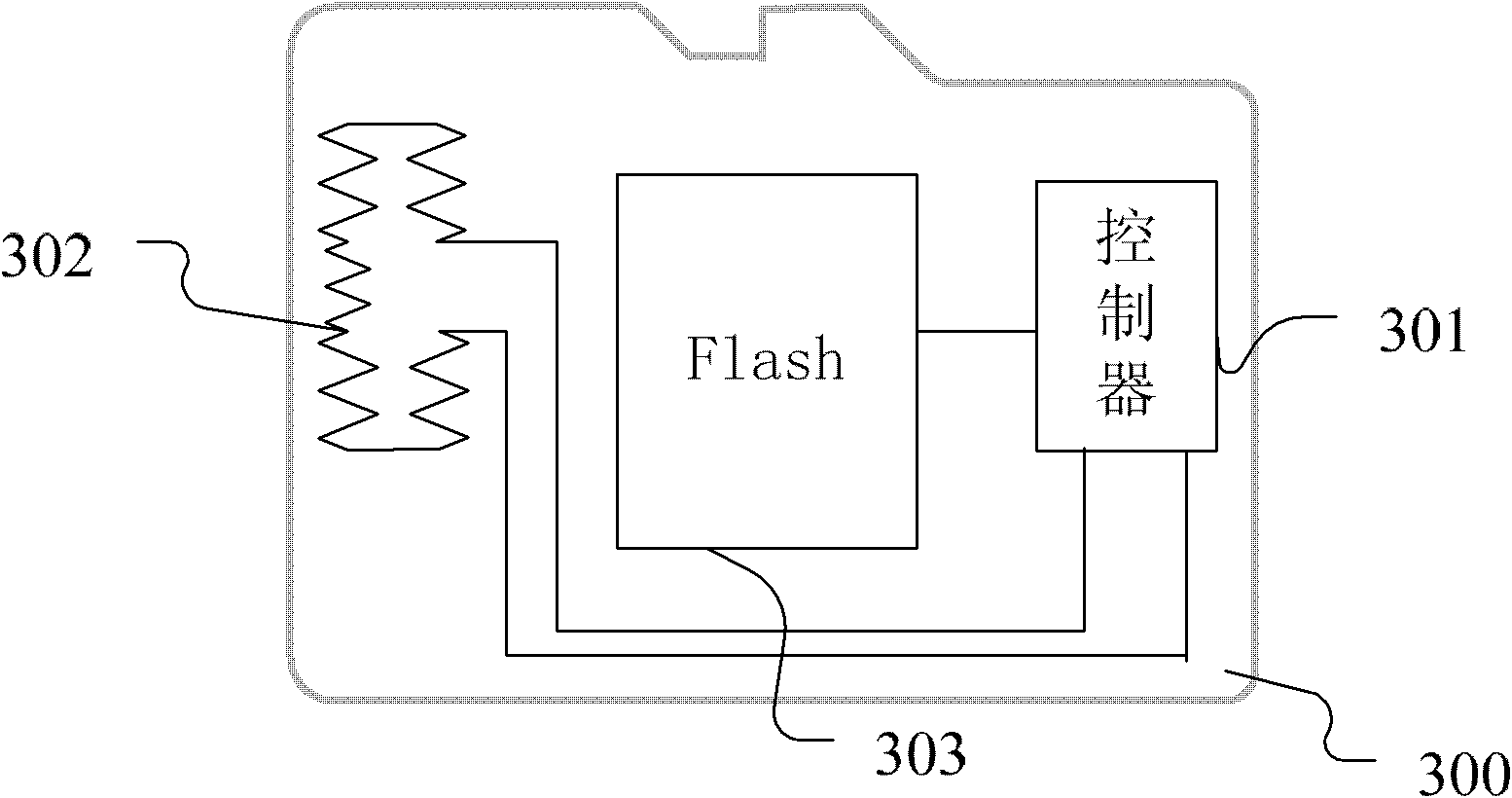

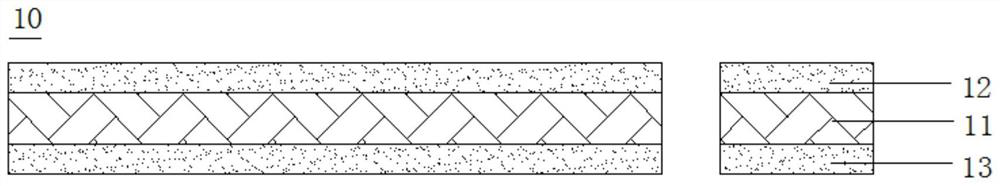

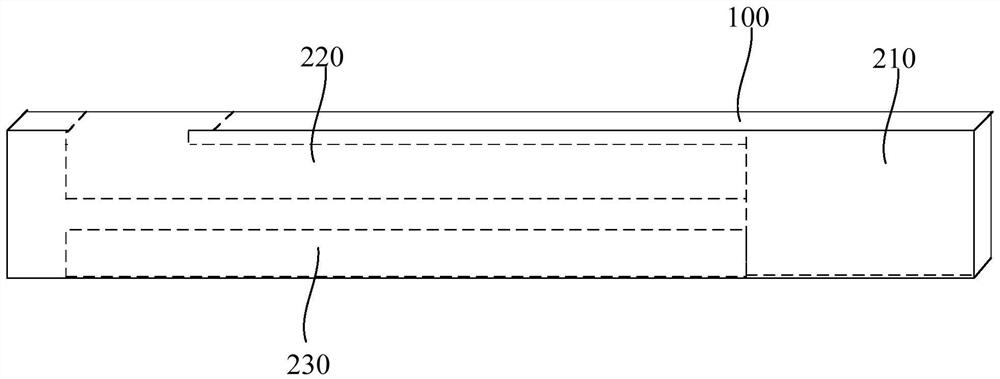

Dual-interface SD card

InactiveCN101853422ASecurity Information InteractionMiniaturizationAntenna supports/mountingsRecord carriers used with machinesMiniaturizationSmart card

The invention discloses a dual-interface SD card and belongs to the technical fields of mobile communication equipment and mobile payment. The dual-interface SD card comprises a card substrate, a controller, an intelligent card chip, a storage, and a micro antenna, wherein the intelligent card chip and the storage are connected with the controller respectively; the intelligent card chip is connected with the micro antenna through a corresponding antenna pin; and the controller, the intelligent card chip, the storage, and the micro antenna are embedded in the card substrate. By integrating a radio frequency antenna through low temperature co-fired ceramic, lamination, thin film and film coating, and other technology, and by embedding the antenna into the conventional SD card, the embedding and miniaturization of the antenna are realized.

Owner:BEIJING HUADA ZHIBAO ELECTRONICS SYST

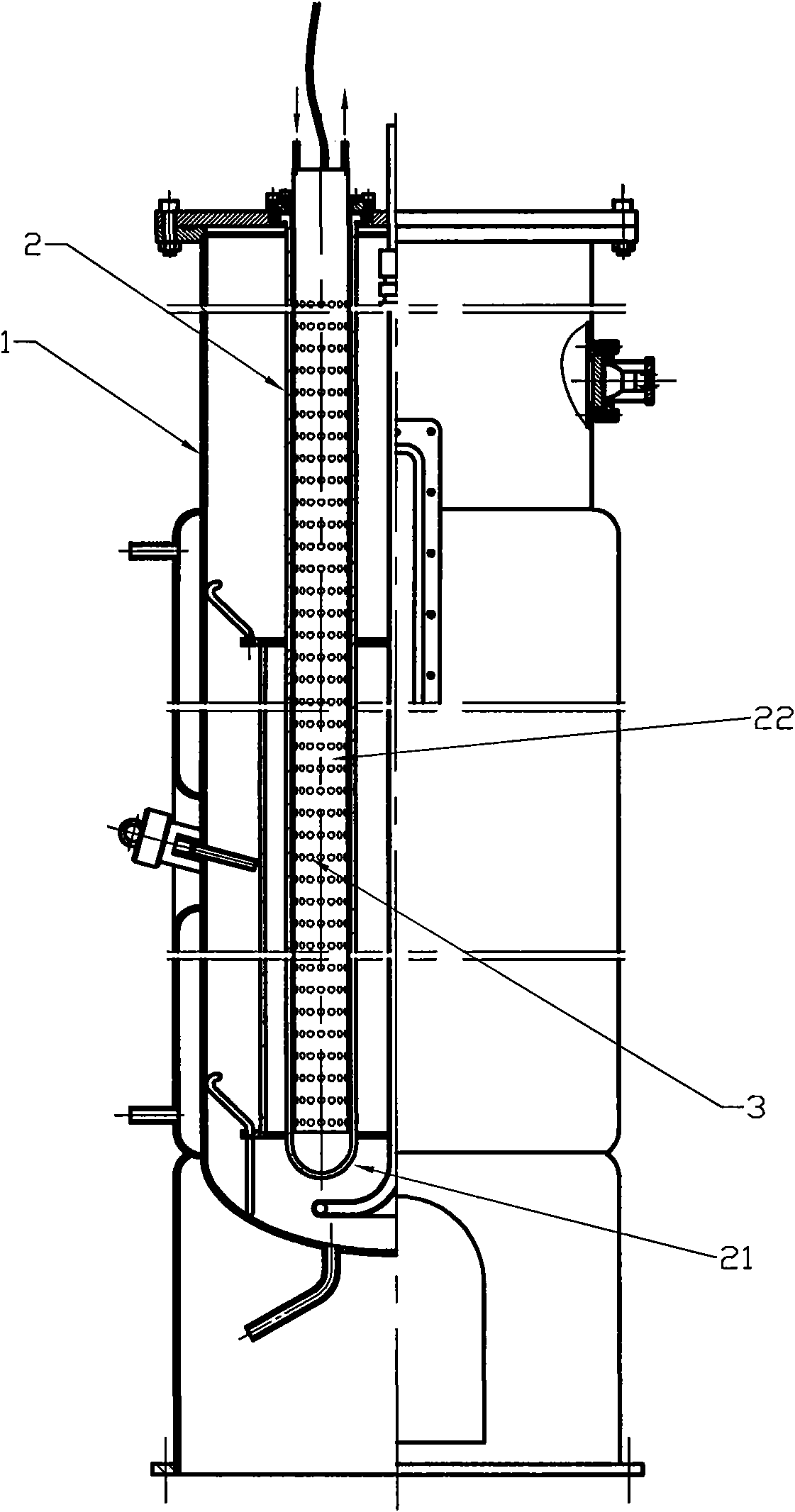

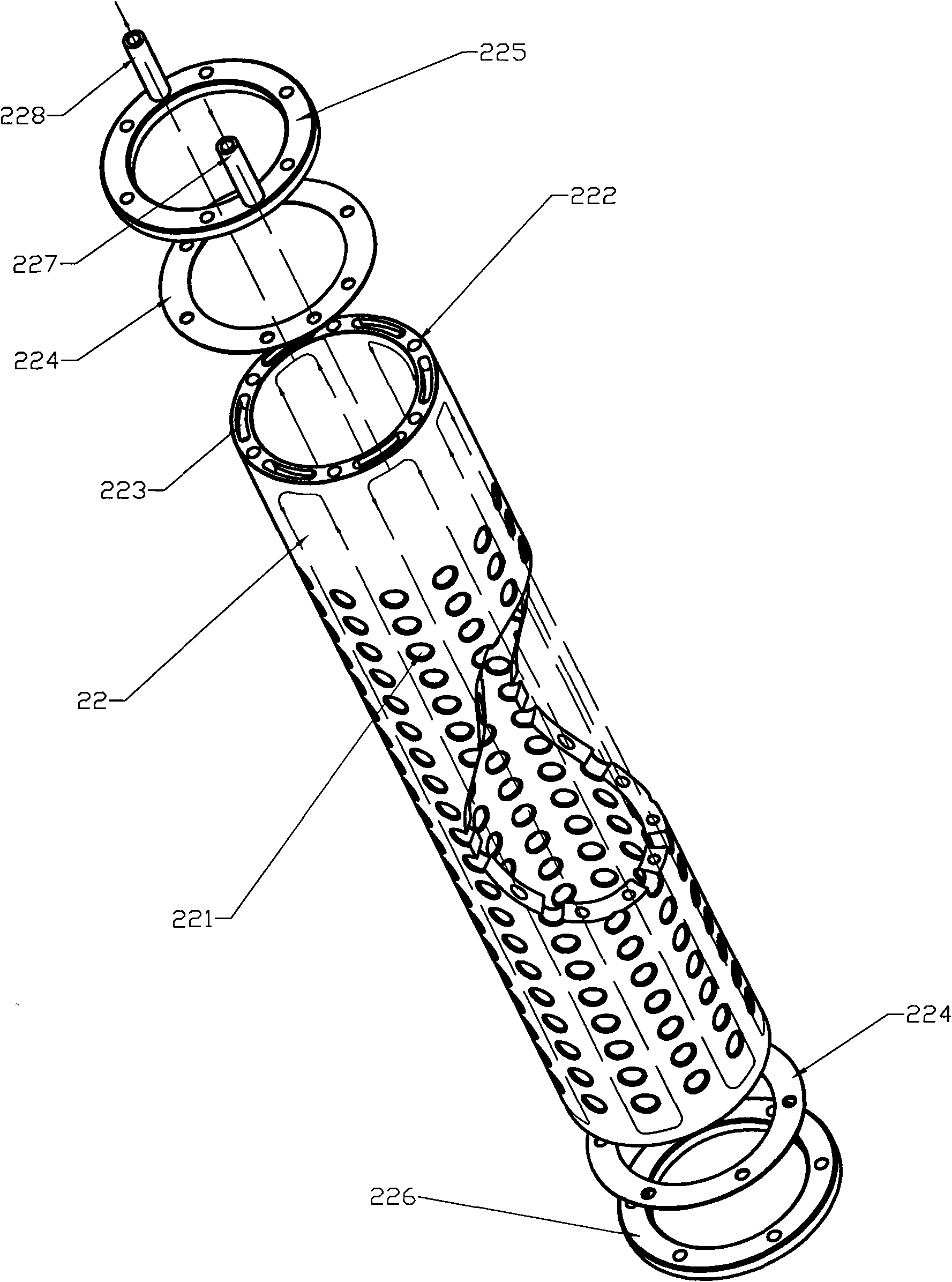

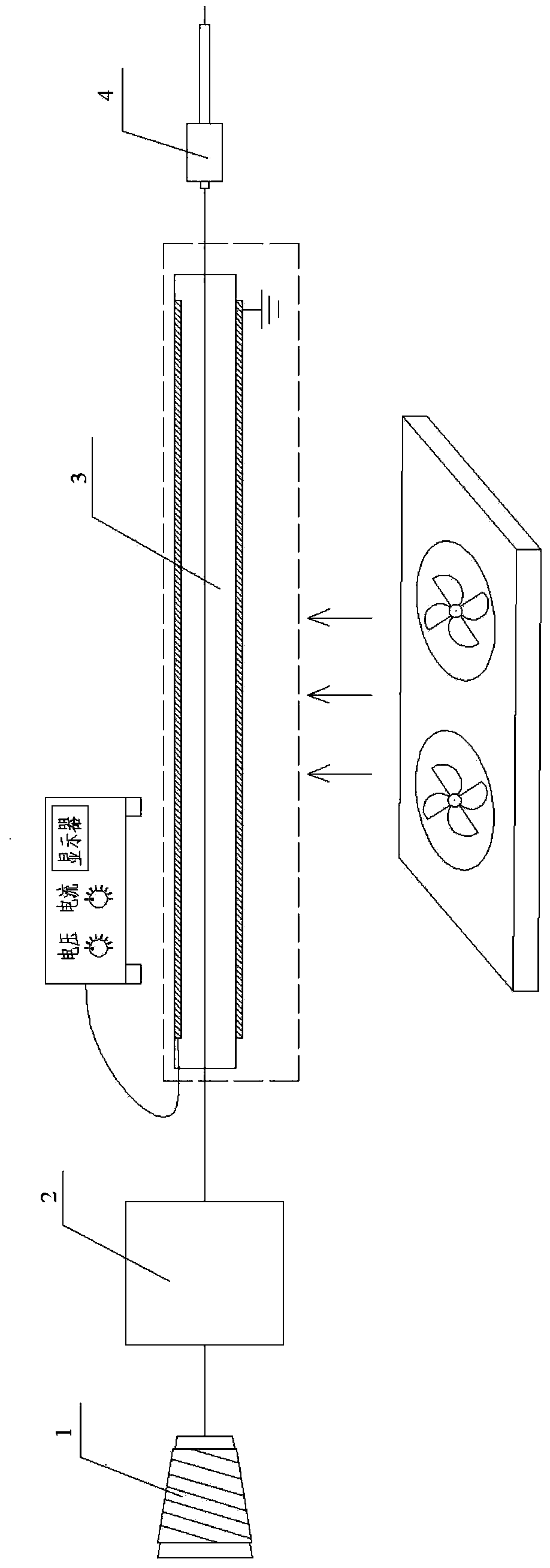

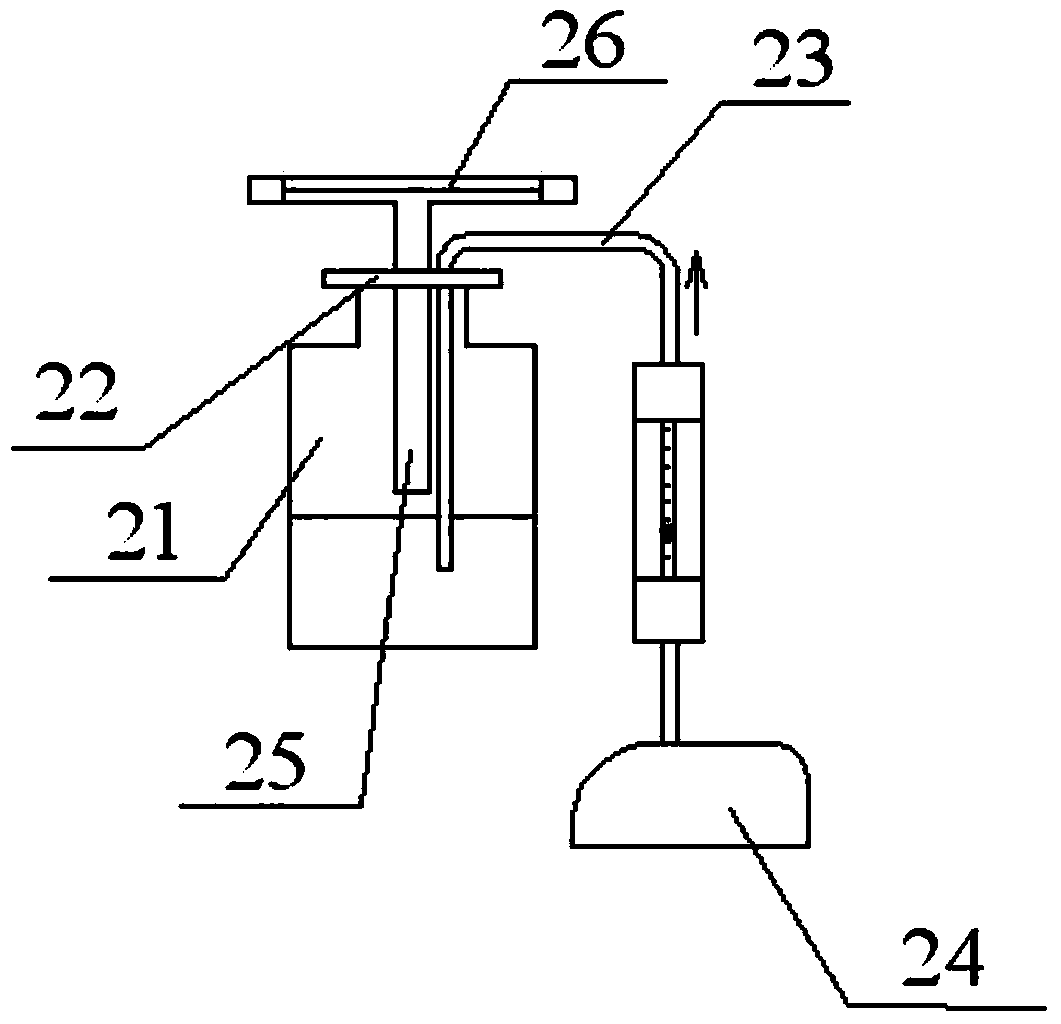

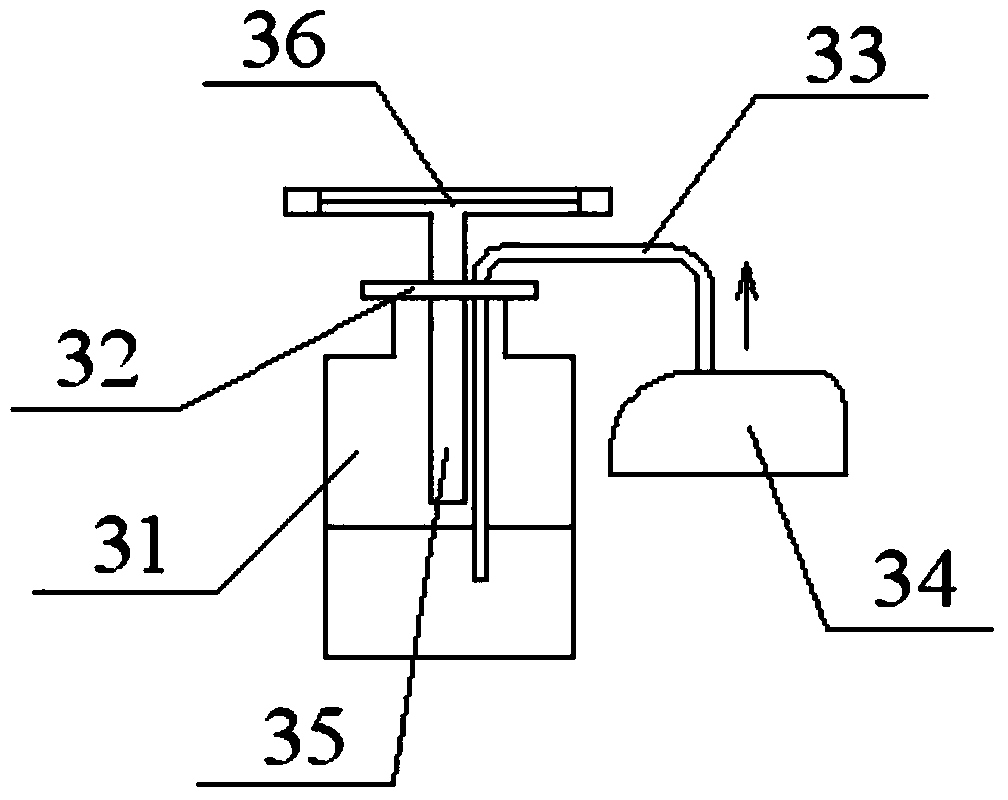

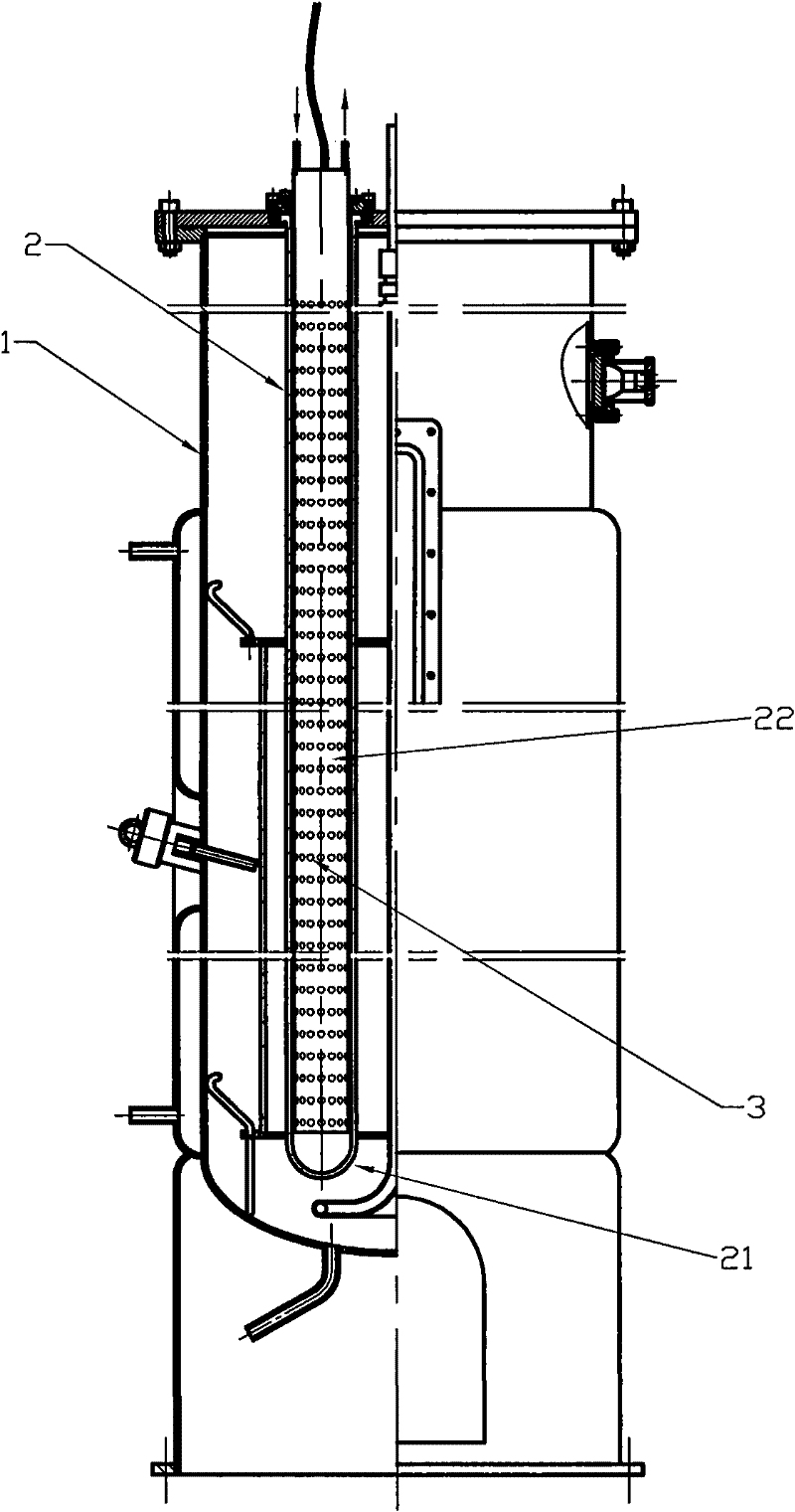

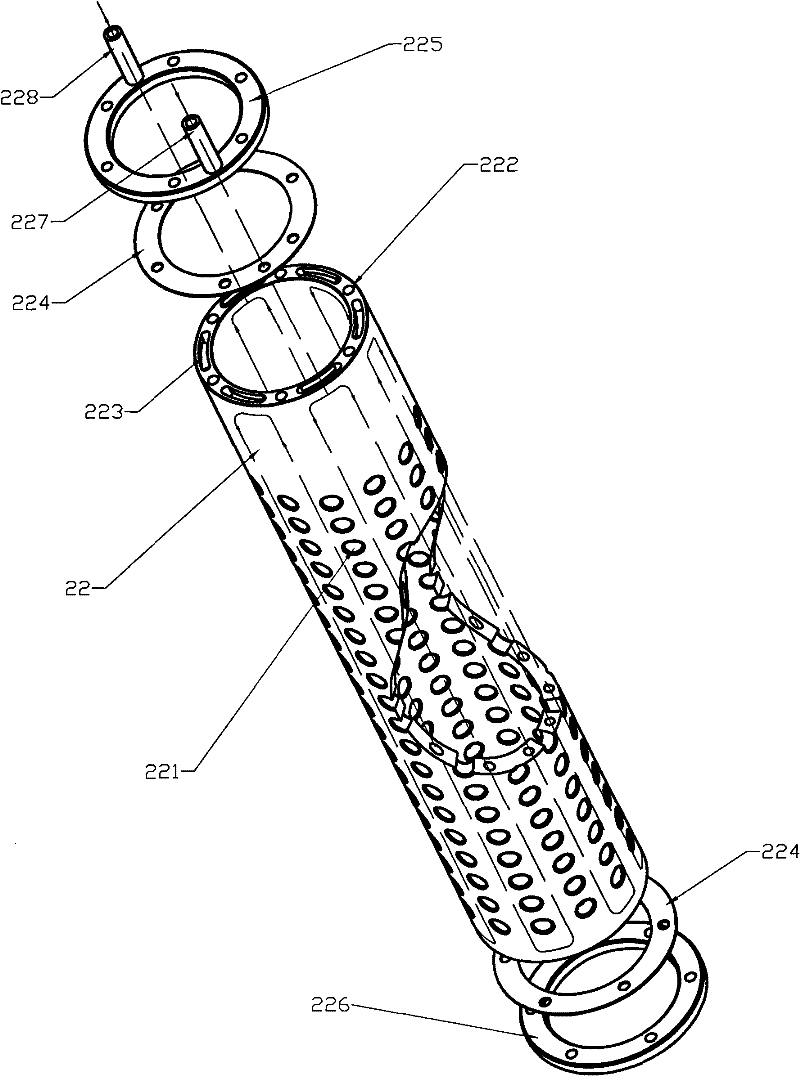

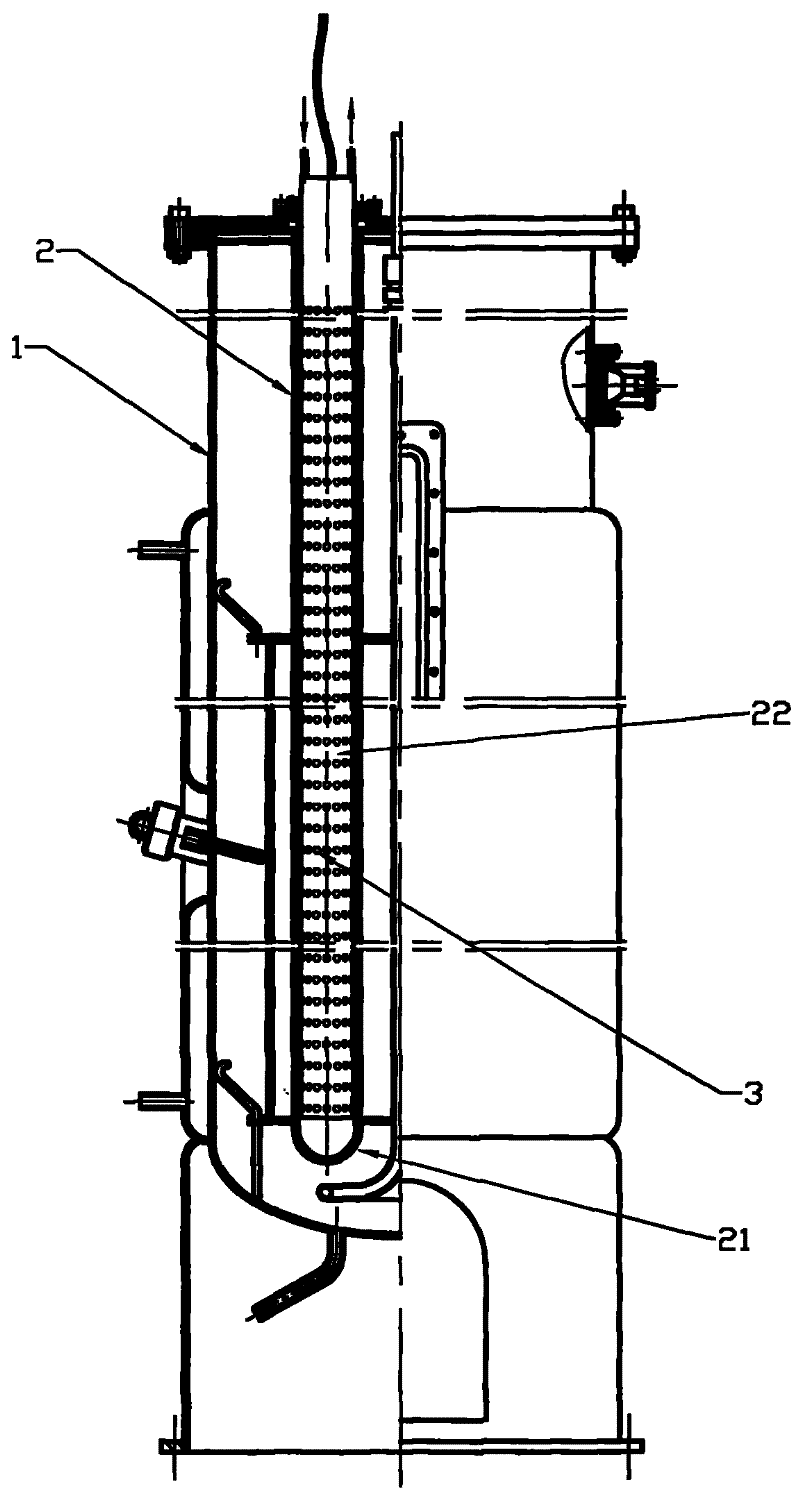

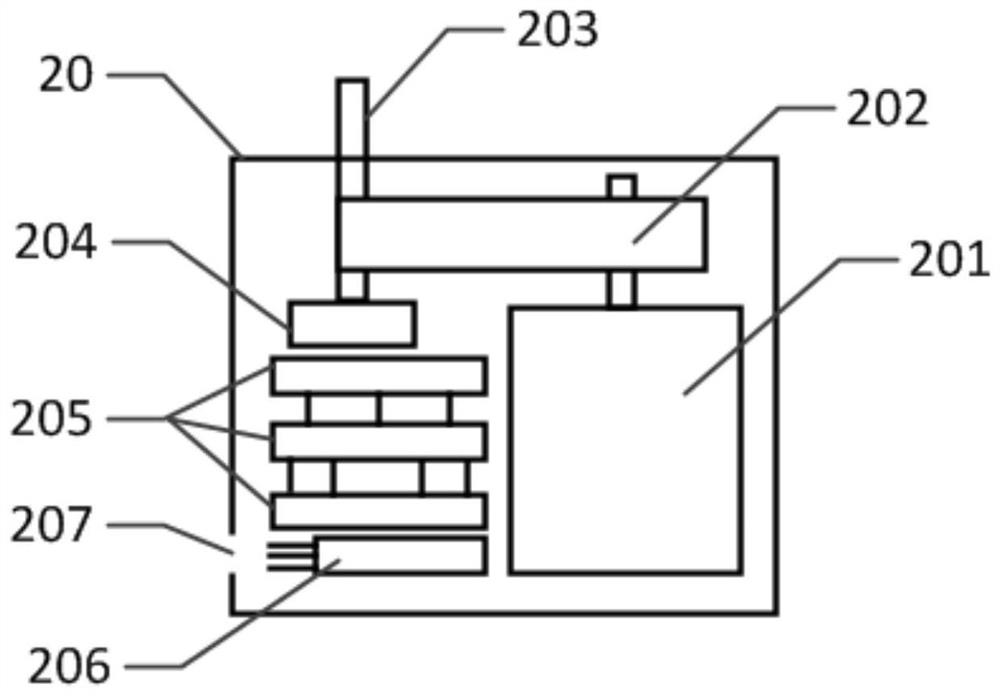

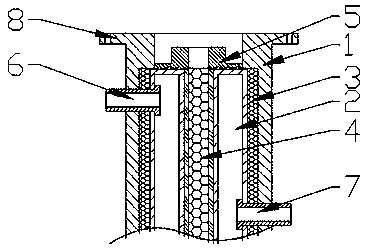

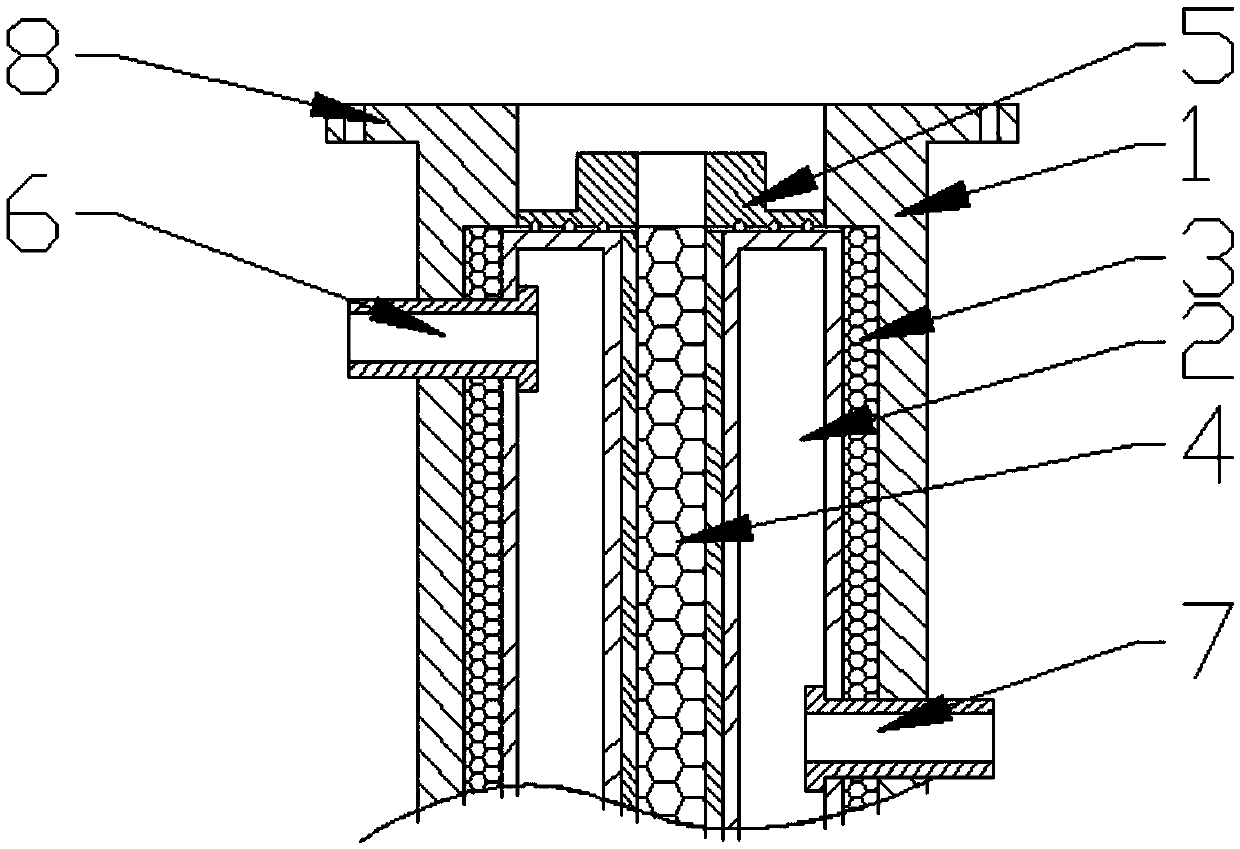

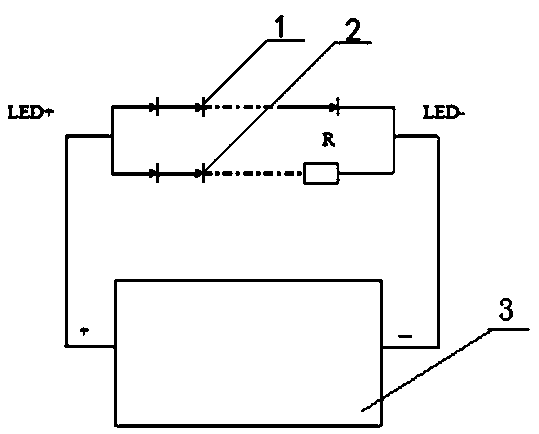

LED light source bioreactor

ActiveCN101629142AReduce volumeIncrease brightnessPhotobioreactorsTissue/virus culture apparatusPhotobioreactorEngineering

The invention relates to microorganism production equipment which is photosynthetic reaction equipment for photosynthetic bacteria and plant cell culture, in particular to an LED light source bioreactor. The bioreactor comprises a pot body and a luminous tube inserted in the pot body, wherein the luminous tube comprises a transparent glass tube case with a closed lower end and a tubular LED bracket inserted in the transparent glass tube case. The upper end of the transparent glass tube case is fixed on a top cover of the pot body; a plurality of LED mounting holes are distributed on the tube wall of the LED bracket; and LEDs are arranged in the LED mounting holes. The invention has the advantages of small size of a light source arranged in a culture pot, easy regulation, little heat radiation in work, strong radiating ability, high utility ratio of the light source, low energy consumption and long service life.

Owner:王科

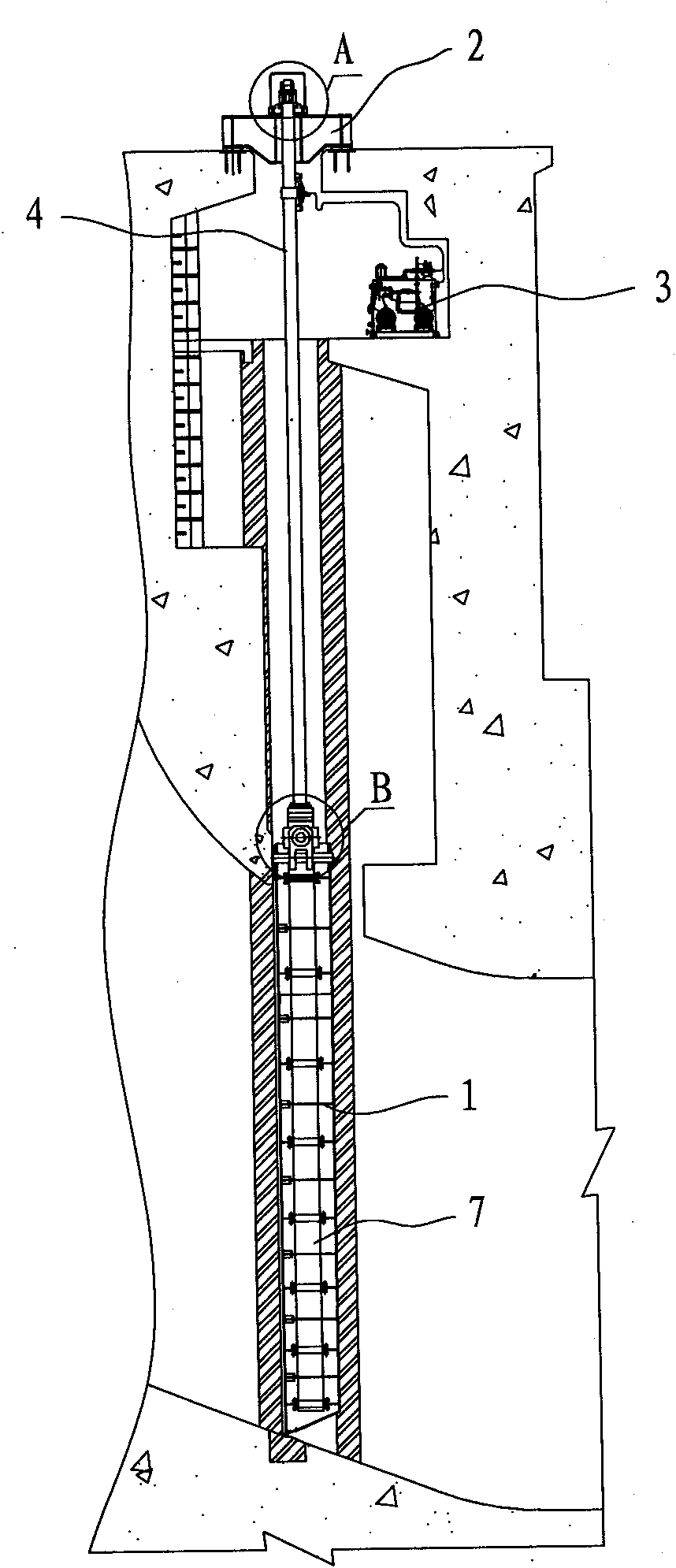

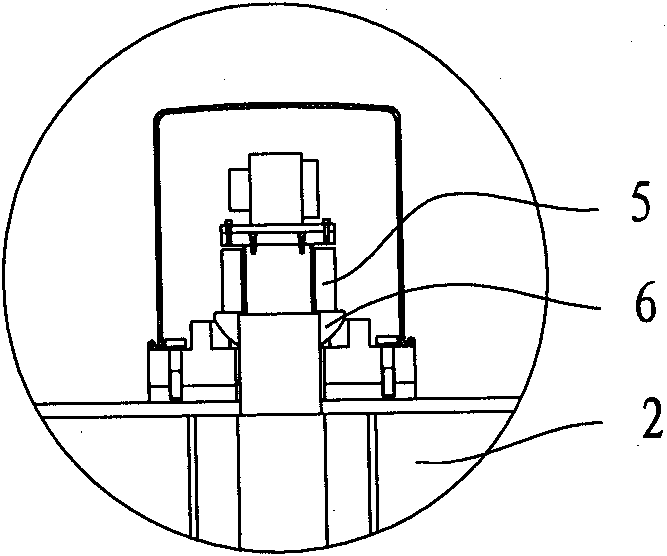

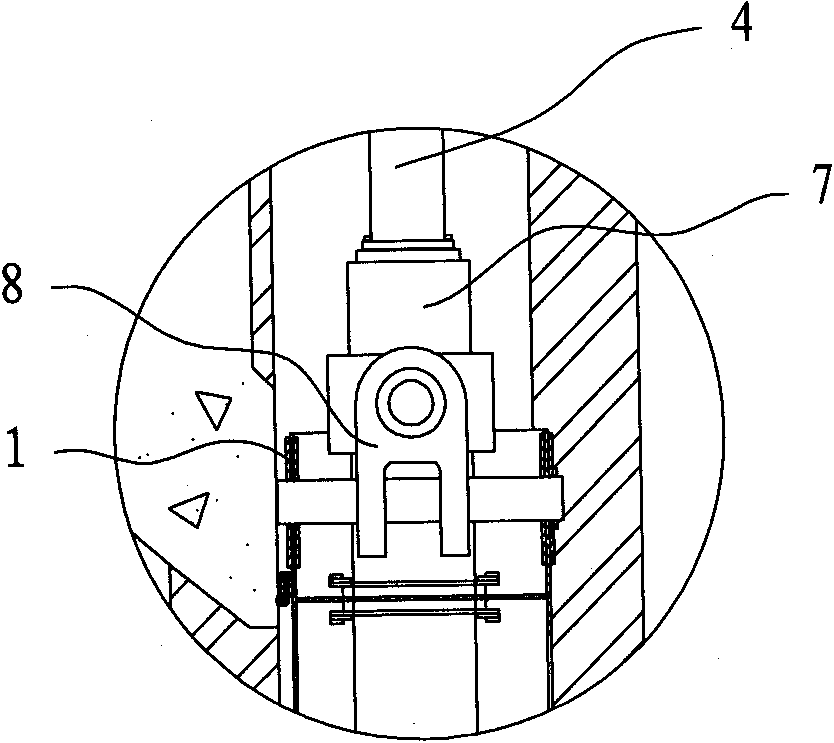

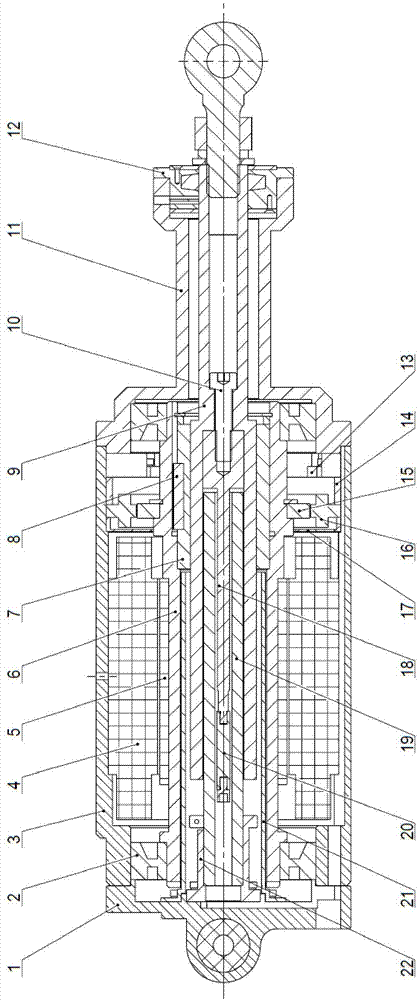

Power station emergency gate using inverted hydraulic hoist

ActiveCN101851907AEasy to processRealize underwater sportsBarrages/weirsWater-power plantsThermal sprayingPower station

The invention discloses a power station emergency gate using an inverted hydraulic hoist, comprising a hydraulic hoist. and a gate body arranged below a dam, wherein the hydraulic hoist comprises an oil cylinder, an open-close bracket, a hydraulic pump station and a control apparatus, wherein the open-close bracket is arranged at the top of the dam, the hydraulic pump station is arranged on a gate maintenance platform, the end part of a piston rod of the oil cylinder is pivoted with the open-close bracket; the oil cylinder body is arranged in the gate body and pivoted with the top of the gate body through two connecting rods with the same structure symmetrically arranged at two sides of the upper end of the cylinder body, a built-in displacement sensor is arranged at the end part of the piston rod, waterproof proximity switches are arranged at two sides of the gate body, and the external surface of the cylinder body is provided with a metal thermal spraying anticorrosive coating. The invention reduces the mounting height of a dam crest, realizes the built-in oil pipe of the oil cylinder without affecting dam surface sceneries, and can slightly swing to adapt the gate displacement because the cylinder body, the gate body and the two connecting rods with the same structure are pivoted with each other to form a four-bar structure.

Owner:YELLOW RIVER ENG CONSULTING

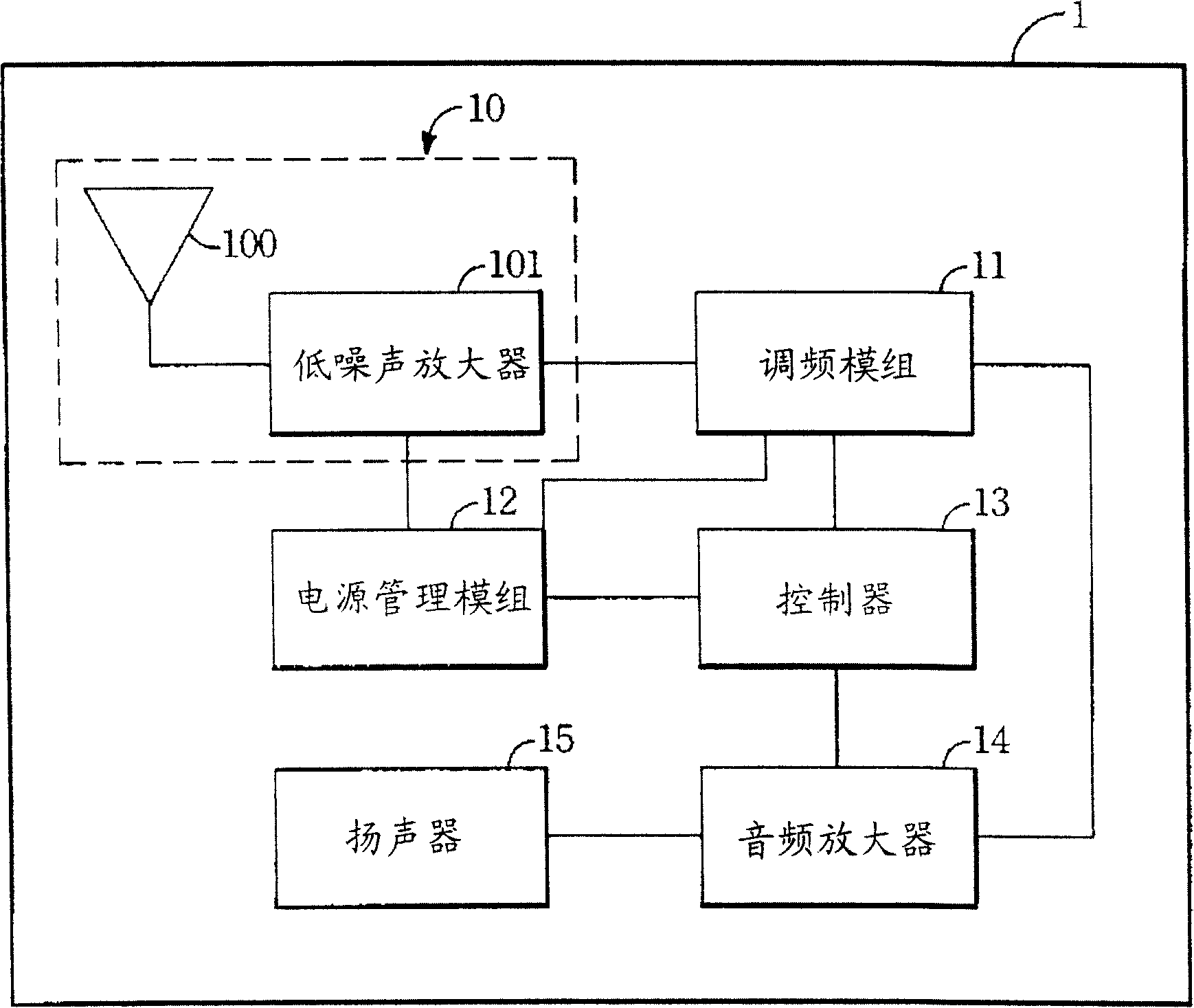

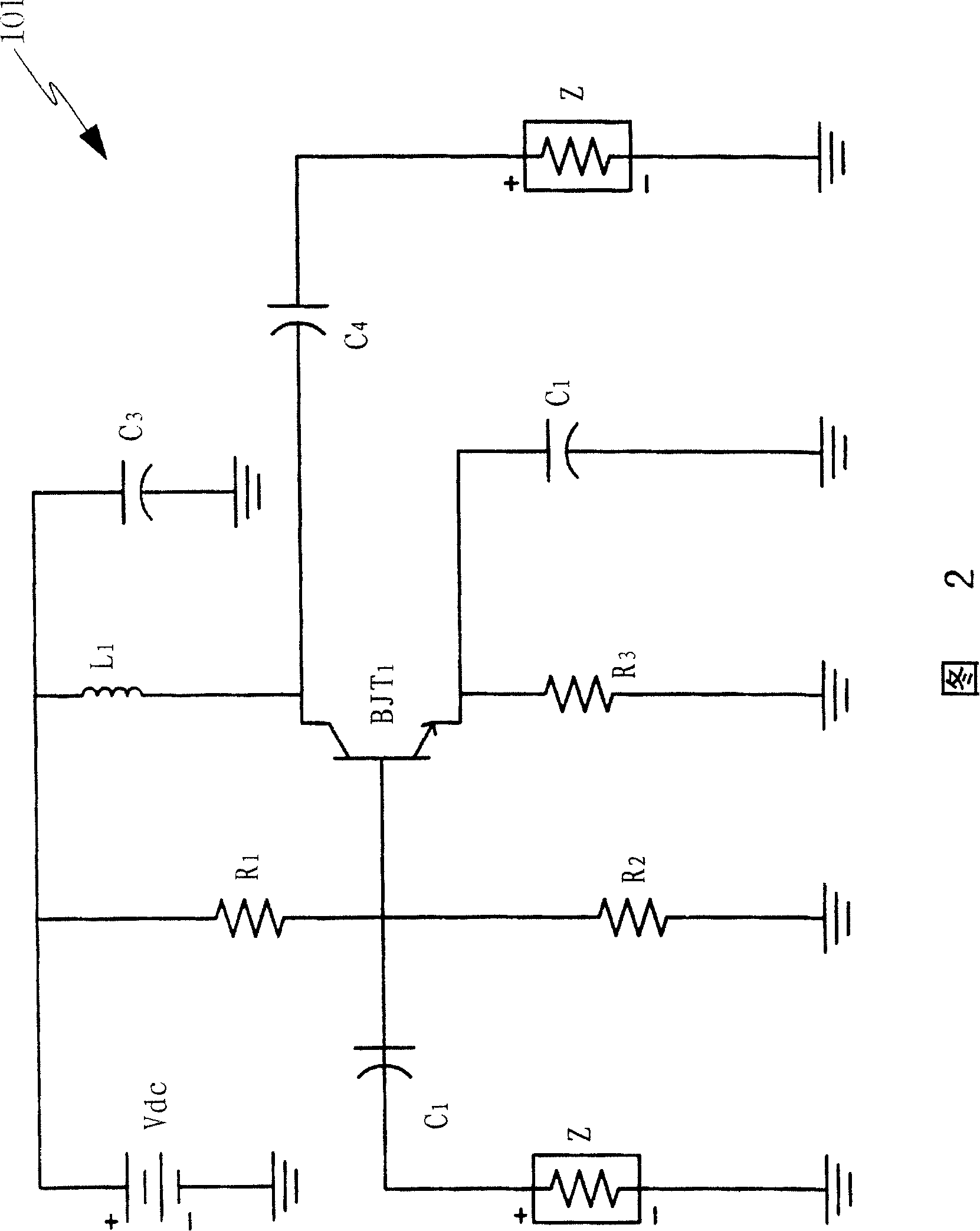

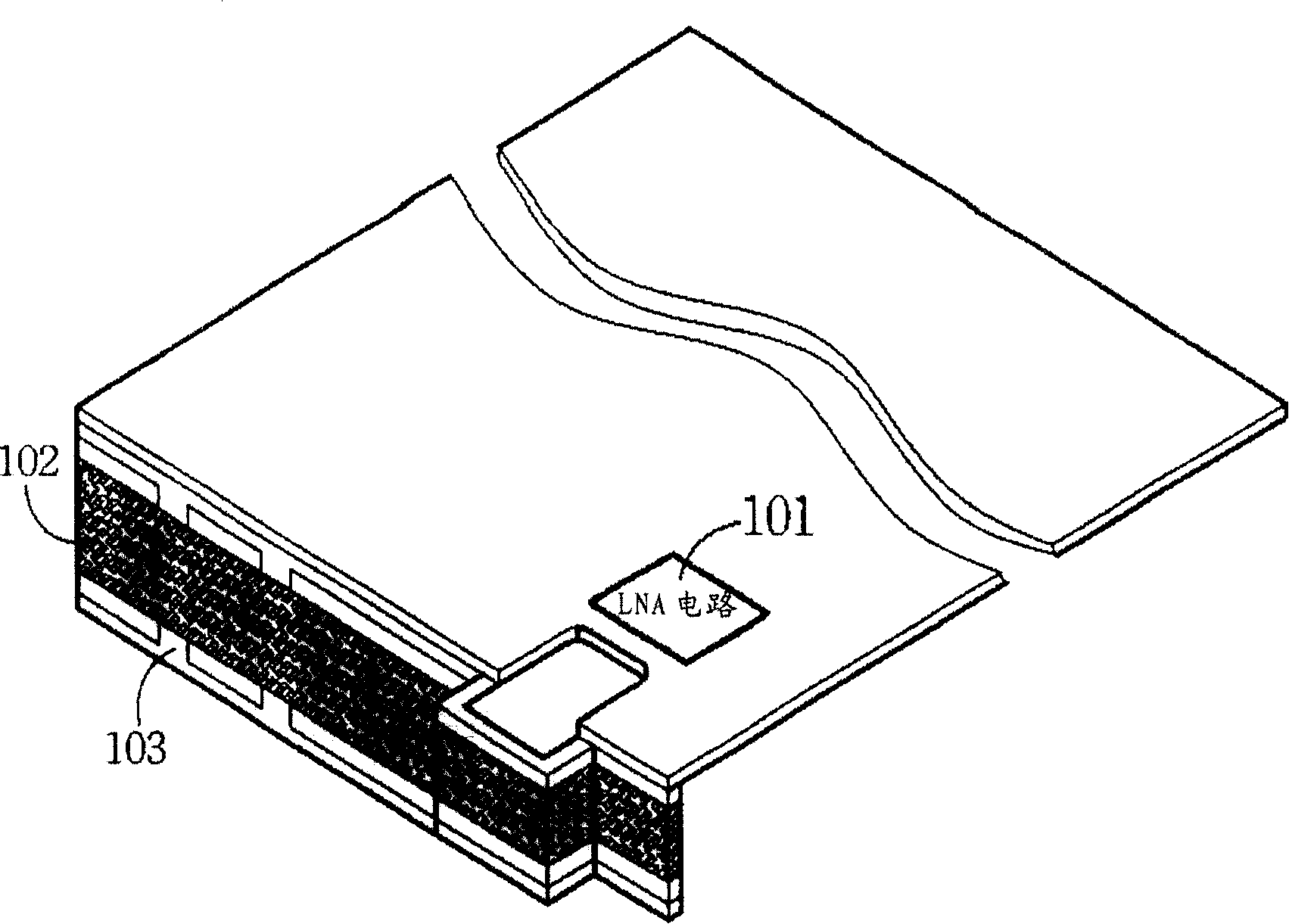

Frequency modulation system circuit

InactiveCN101166032AImprove receiver sensitivityCompensation lossTransmissionAudio power amplifierEngineering

This invention discloses an FM system circuit including: an antenna circuit with an antenna, a low noise amplifier and a matching circuit, a support structure and a feed line for receiving signals, an FM module connecting to the antenna circuit for processing the FM signals and converting them to audio signals and a controller connected to the FM module for configuring and outputting audio signals, in which, the size of the antenna circuit can be reduced for being placed in an electronic device since the low noise amplifier and the matching circuit improve receiving of the antenna circuit.

Owner:INVENTEC(NANJING) TECH CO LTD

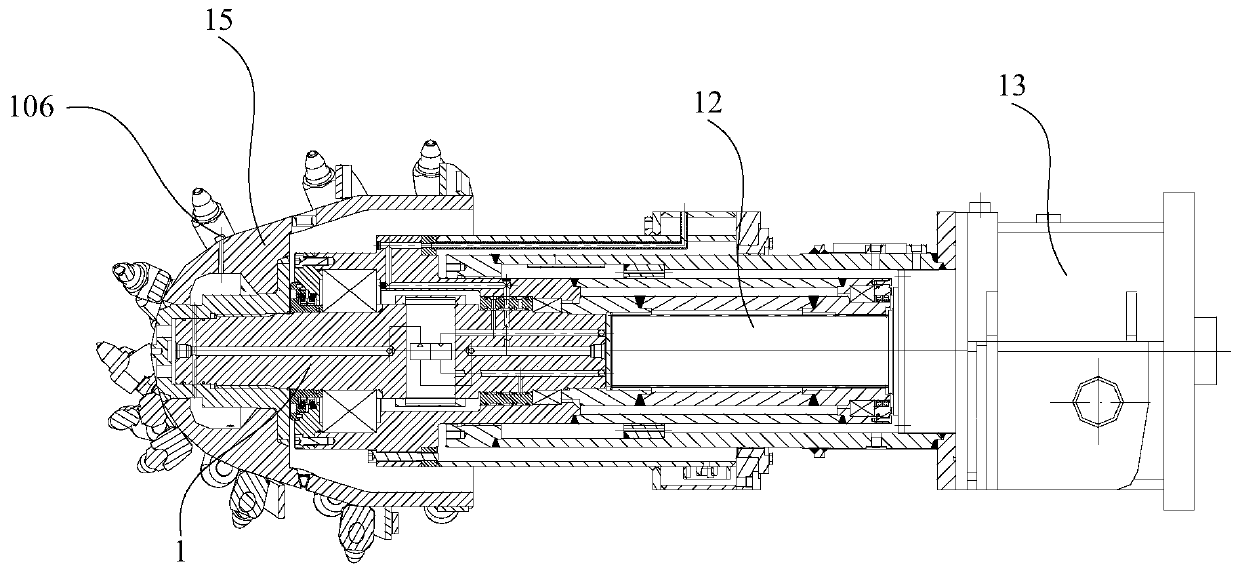

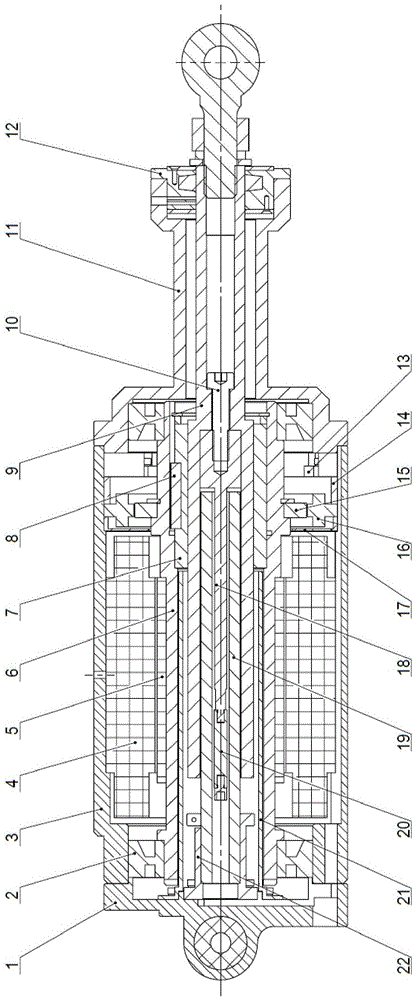

Highly integrated electromechanical actuator

ActiveCN103545977AAchieve direct connectionGuaranteed accuracyMechanical energy handlingLinear variable differential transformerAnti jamming

Owner:SHANGHAI JIAO TONG UNIV

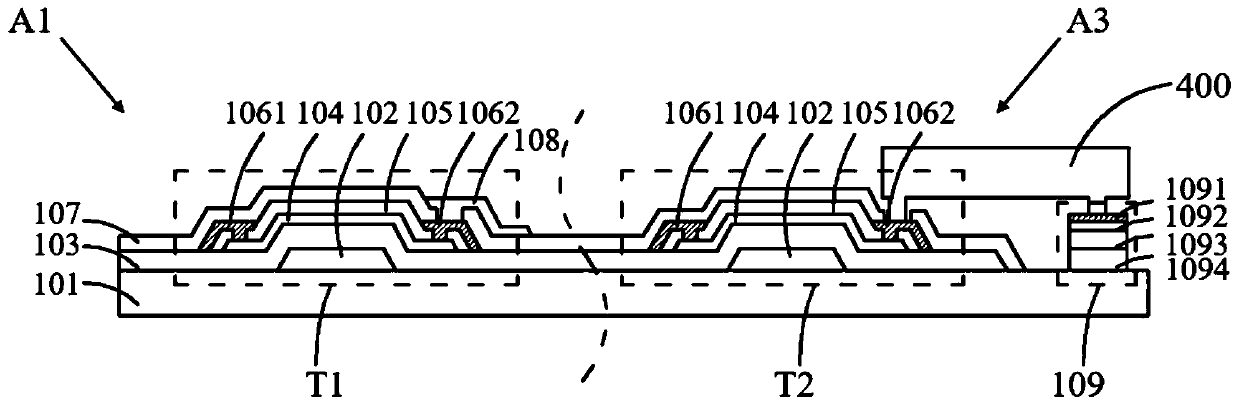

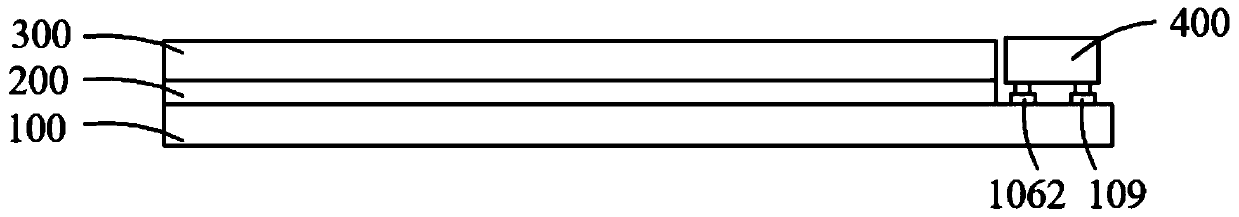

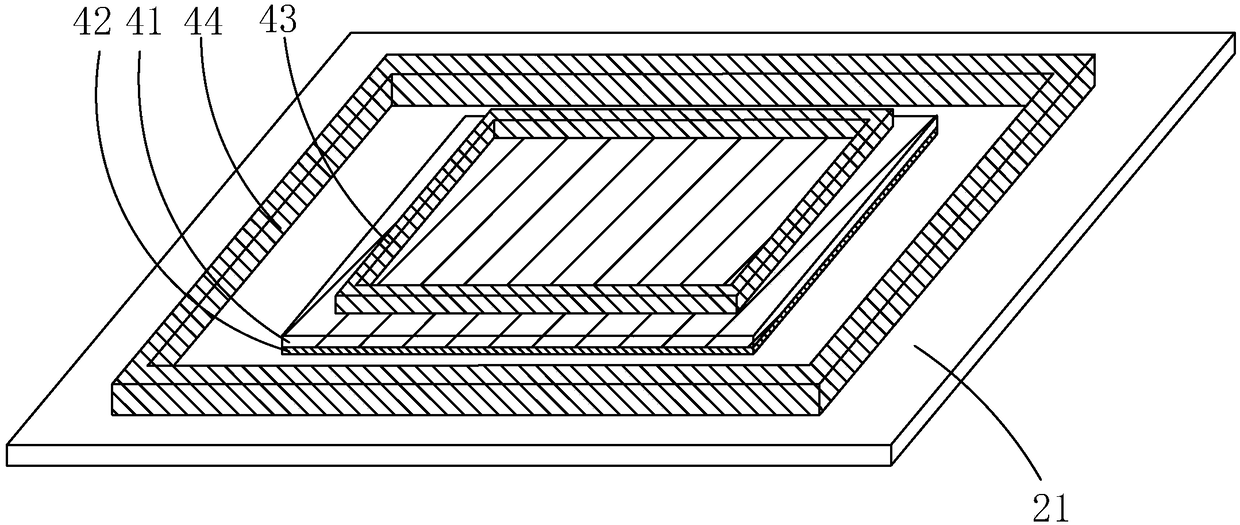

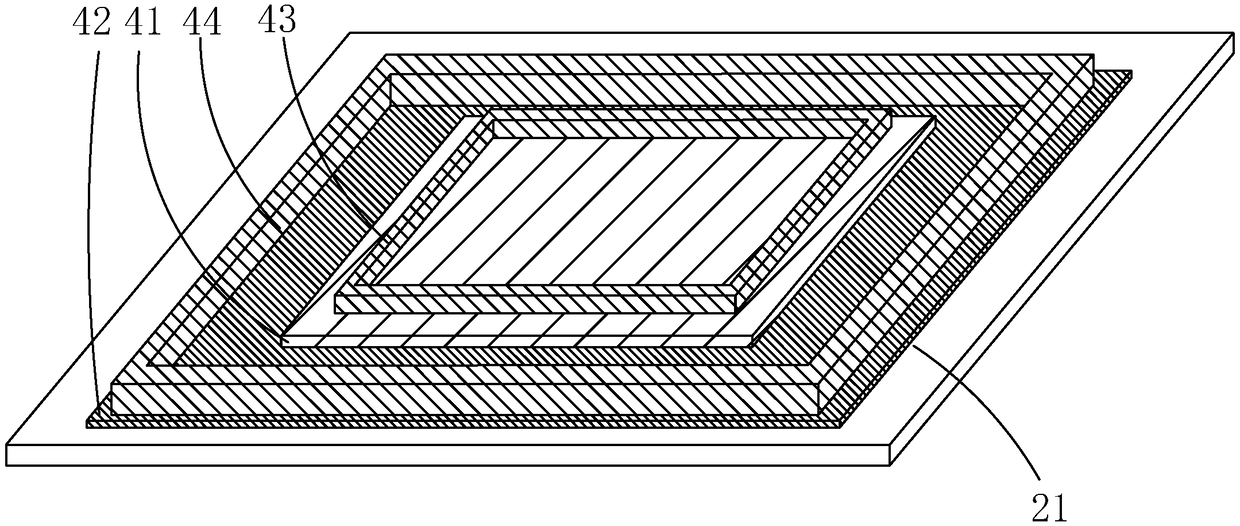

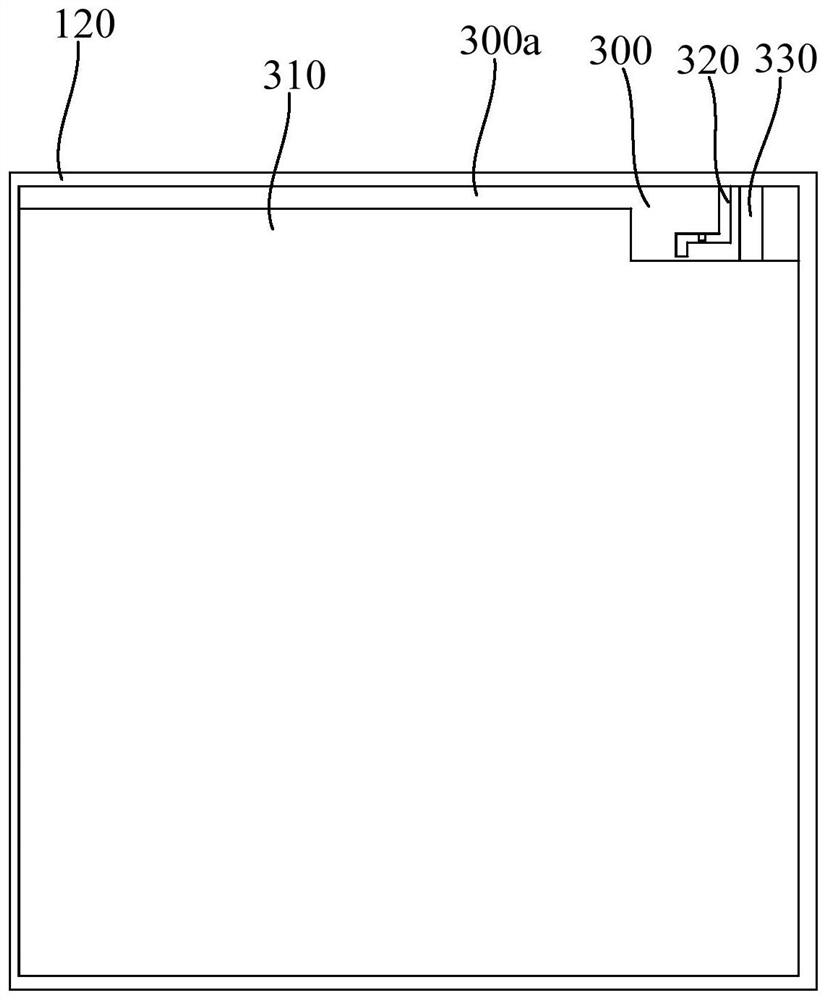

Display panel and preparation method thereof

ActiveCN111223905AAchieve controllabilityReduce light intensitySolid-state devicesSemiconductor/solid-state device manufacturingFlash-lampMaterials science

The invention discloses a display panel and a preparation method thereof. The display panel comprises an array substrate, and the array substrate comprises a display area and a non-display area; a plurality of display area thin film transistors arranged in an array are configured on the array substrate; and the non-display area is arranged it the periphery of the display area, and comprises a flash lamp area; and the flash lamp area is configured with at least one flash lamp area thin film transistor, at least one external electrode corresponding to the at least one flash lamp area thin film transistor, and at least one light emitting diode electrically connected with the at least one flash lamp area thin film transistor and the at least one external electrode. According to the display panel, the flash lamp can be arranged in the display panel, so that the display panel has richer functions and market competitiveness.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

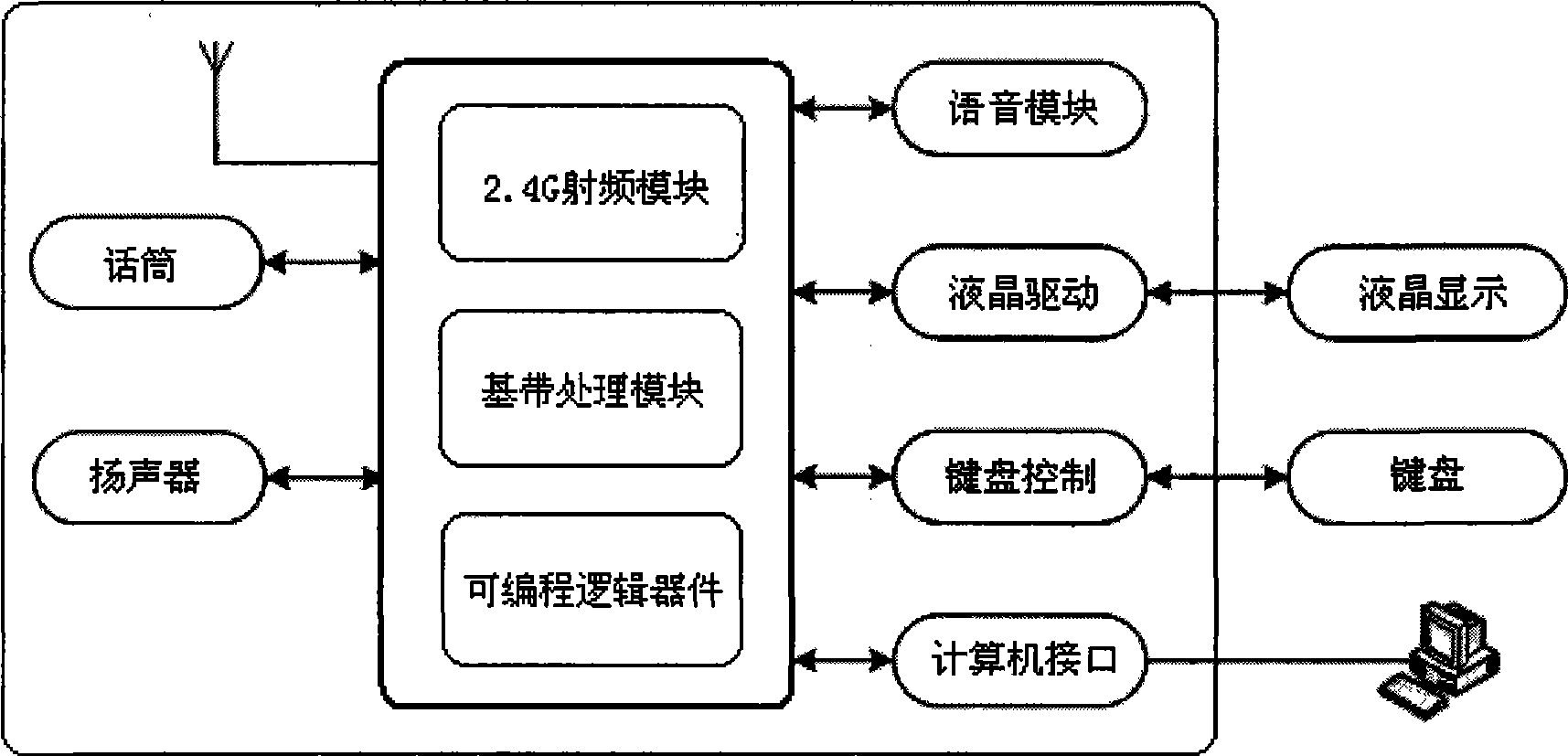

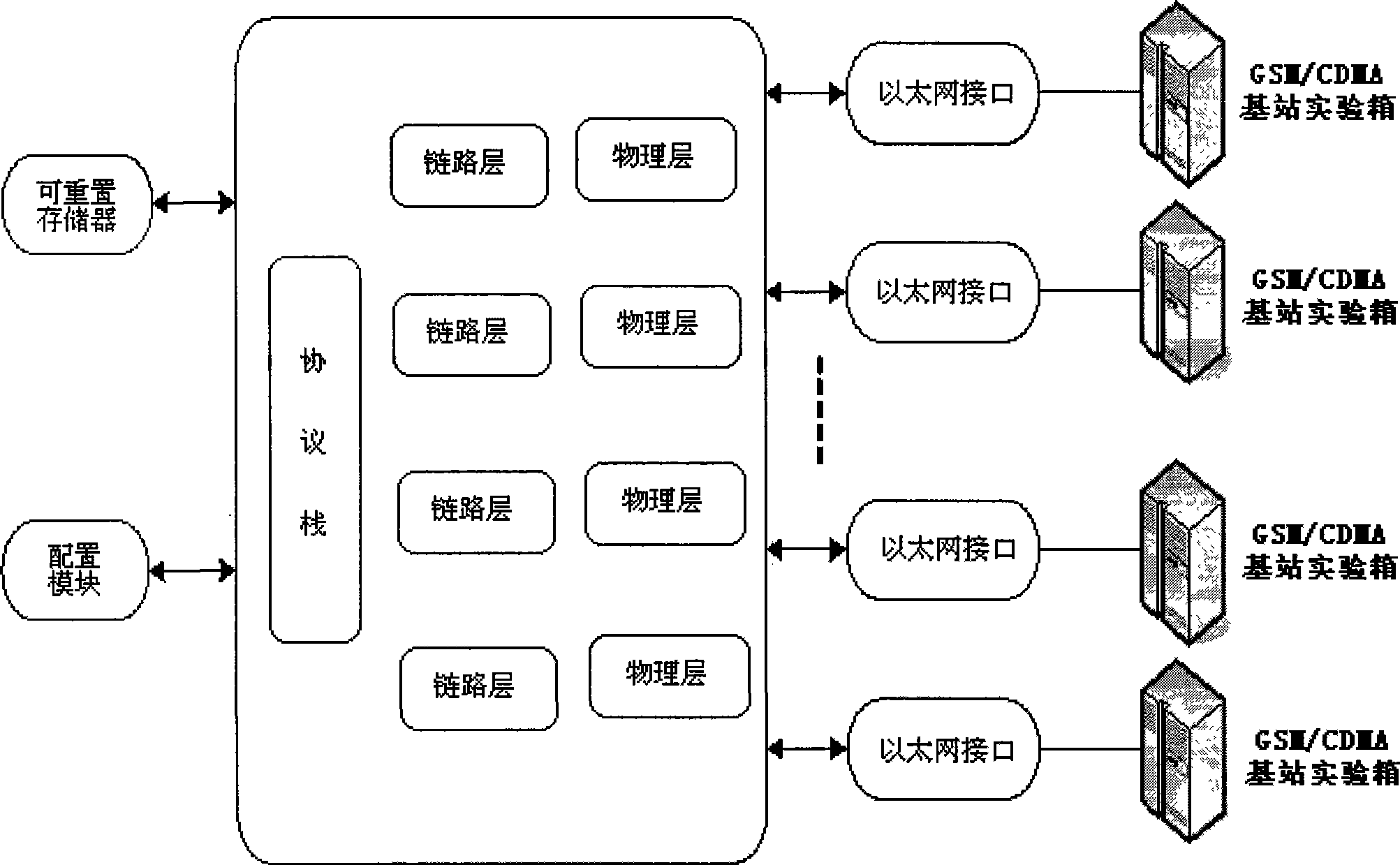

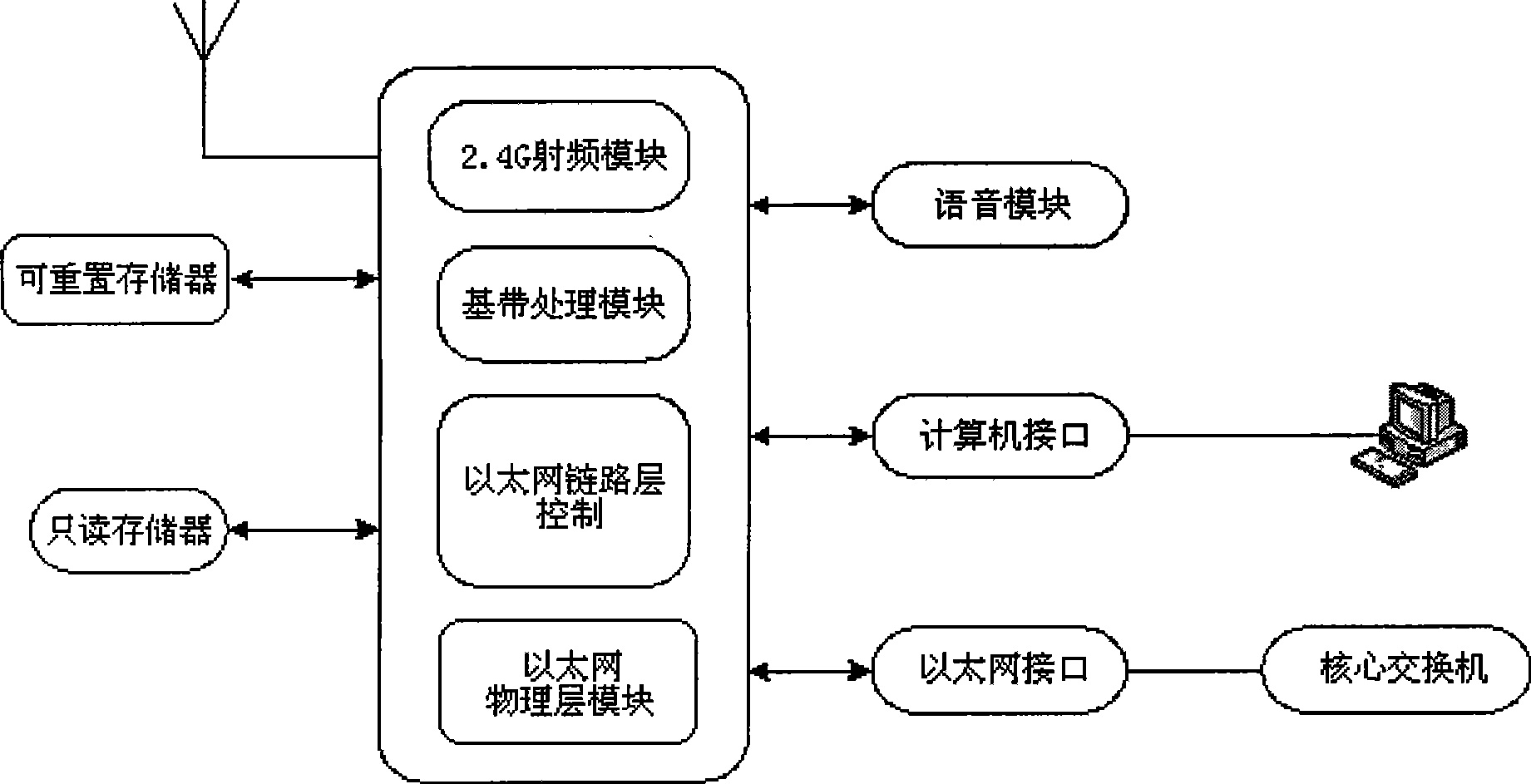

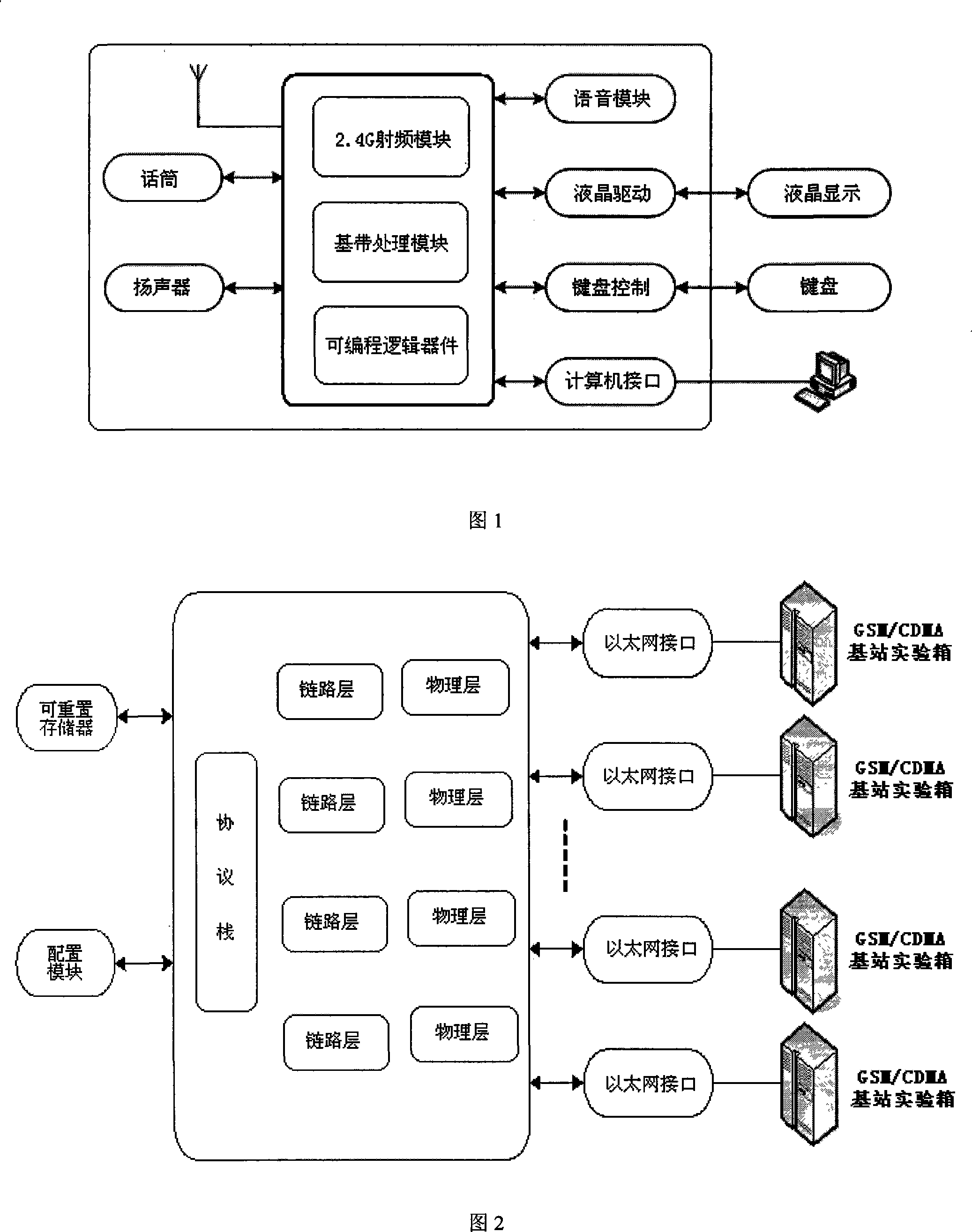

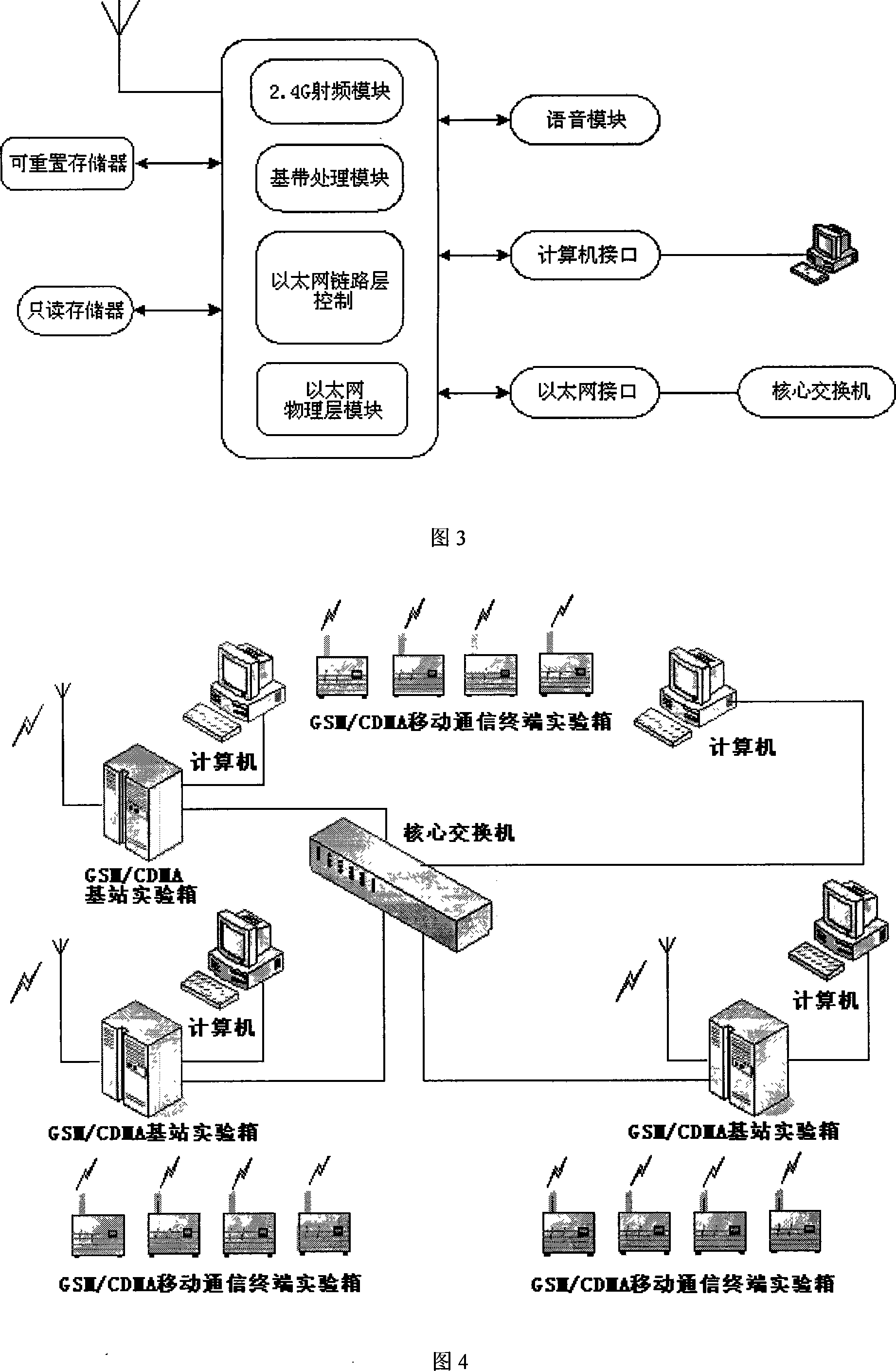

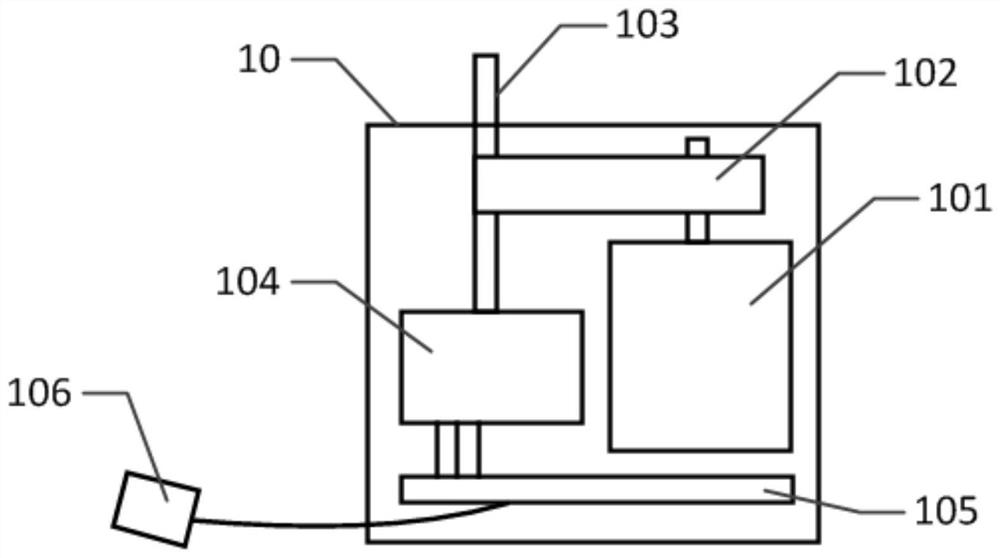

Wireless communication and group net experiment system thereof

ActiveCN101136147BFlexible and easier to operateSmall sizeEducational modelsApplication softwareComputer science

The teaching apparatus is a wire-less communication network experiment system, which comprises a GSM / CDMA mobile communication terminal experiment box, a GSM / CDMA base-station experiment box, a computer connected with the GSM / CDMA base-station experiment box and fitted with application software, a kernel exchanger star-shape topologically connected with GSM / CDMA base-station experiment box and a computer connected with the kernel exchanger and fitted with management system software. The experiment system adopts software and hardware to cooperate, experiment course is very visual, and operation is flexible and simple, which can be used for experiments relative to courses such as mobile communication, computer network or Ethernet.

Owner:ZHEJIANG TIANHUANG TECH INDAL

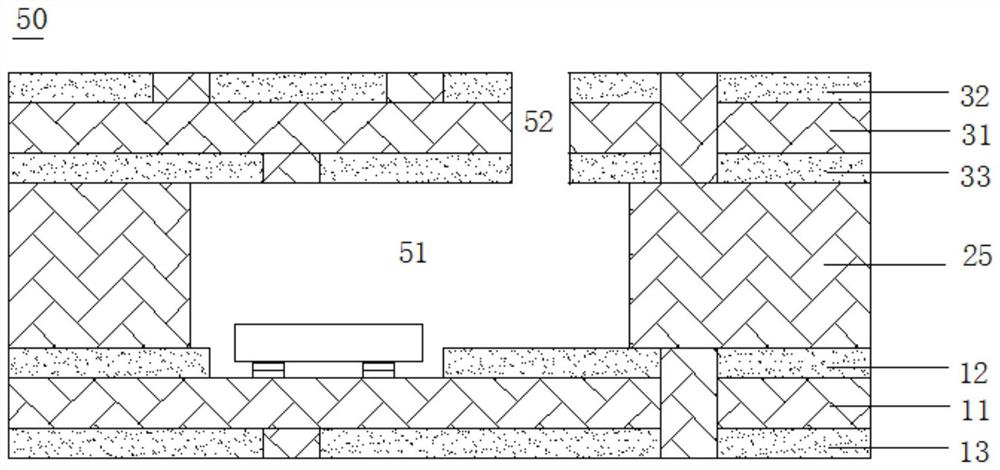

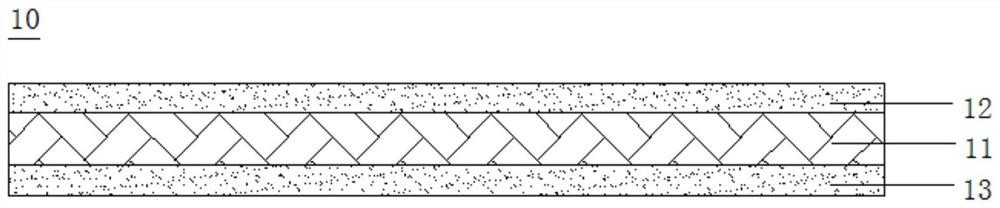

MEMS built-in chip packaging carrier and manufacturing process thereof

PendingCN114368726AImprove alignmentReduce distractionsTelevision system detailsImpedence networksSurface mountingEngineering physics

The invention relates to an MEMS built-in chip packaging carrier plate and a manufacturing process thereof, and the process comprises the following steps: preparing three core plates, namely a first core plate, a second core plate and a third core plate, and drilling and filling holes in the first core plate; an inner layer circuit of the first core board; sMT surface mounting is carried out; etching a second core plate and pressing a film; grooving the film plate; drilling and hole filling of the third core board; an inner layer circuit of the third core board; pressing: pressing the first core plate, the film plate and the third core plate together; and opening the cover. According to the packaging substrate, the function of a built-in chip is achieved, the size of the back cavity is increased under the condition that the size of a device is not increased, the sensitivity and the signal-to-noise ratio of a product are improved, and the packaging substrate conforms to the development trend of device miniaturization.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

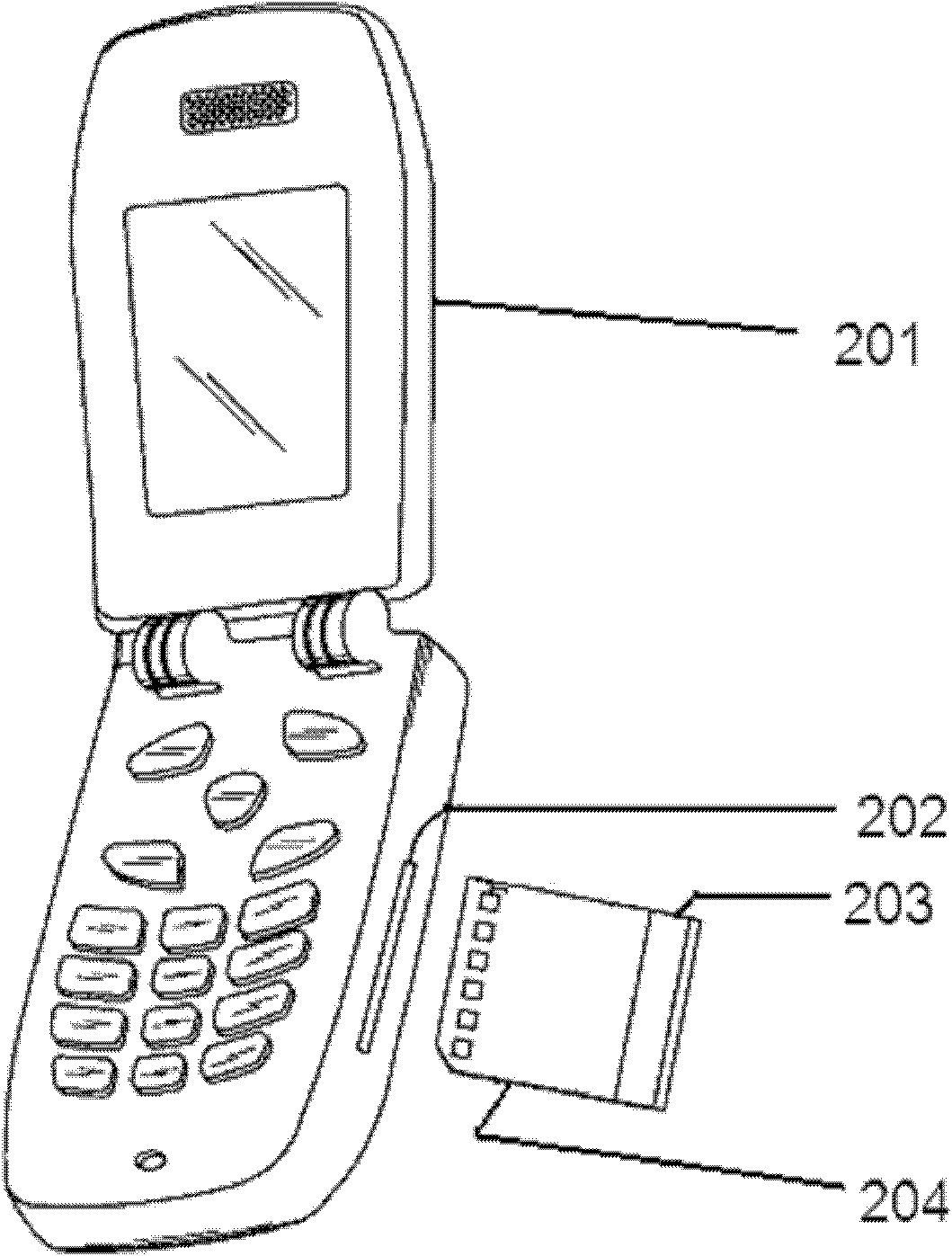

Wireless communication and group net experiment system thereof

ActiveCN101136147AFlexible and easier to operateSmall sizeEducational modelsApplication softwareManagement system

The teaching apparatus is a wire-less communication network experiment system, which comprises a GSM / CDMA mobile communication terminal experiment box, a GSM / CDMA base-station experiment box, a computer connected with the GSM / CDMA base-station experiment box and fitted with application software, a kernel exchanger star-shape topologically connected with GSM / CDMA base-station experiment box and a computer connected with the kernel exchanger and fitted with management system software. The experiment system adopts software and hardware to cooperate, experiment course is very visual, and operation is flexible and simple, which can be used for experiments relative to courses such as mobile communication, computer network or Ethernet.

Owner:ZHEJIANG TIANHUANG TECH INDAL

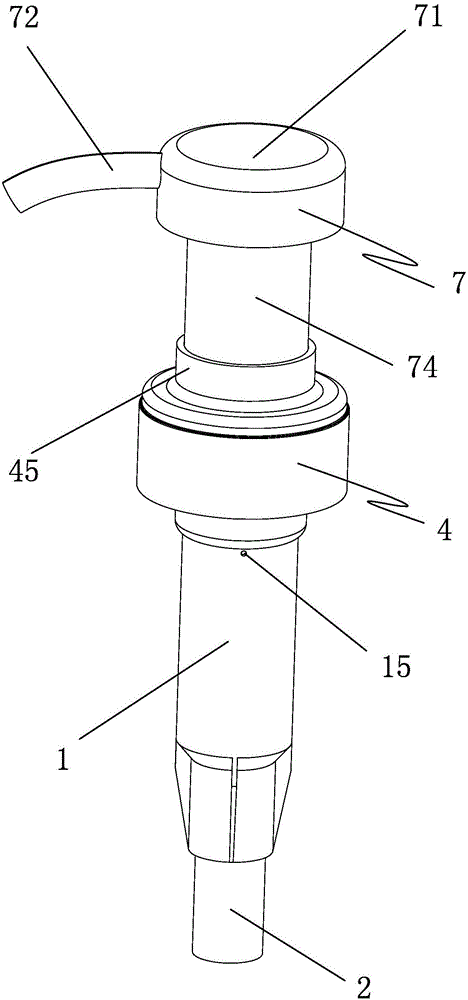

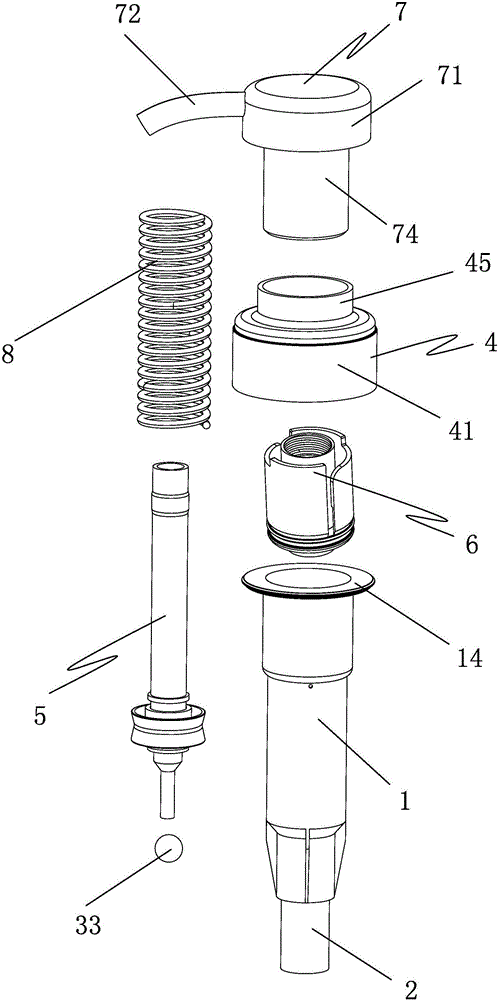

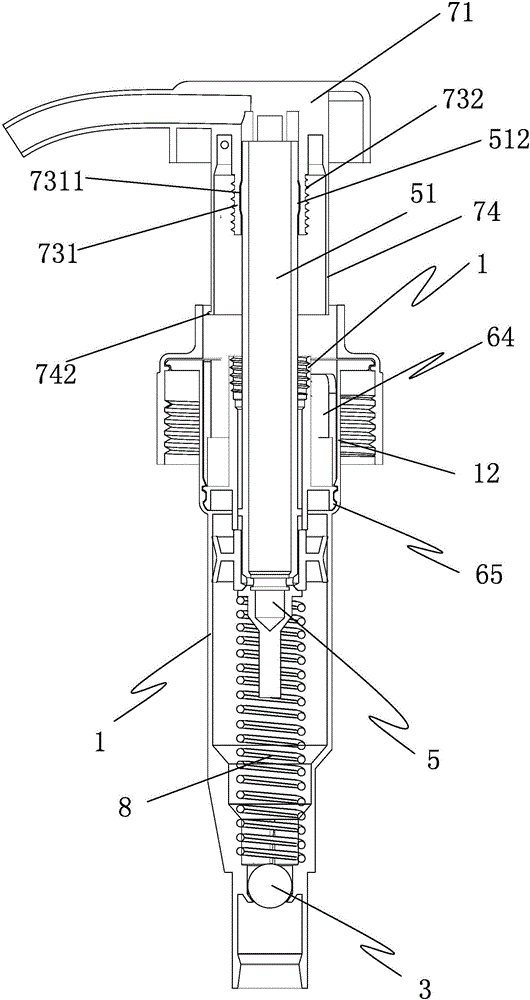

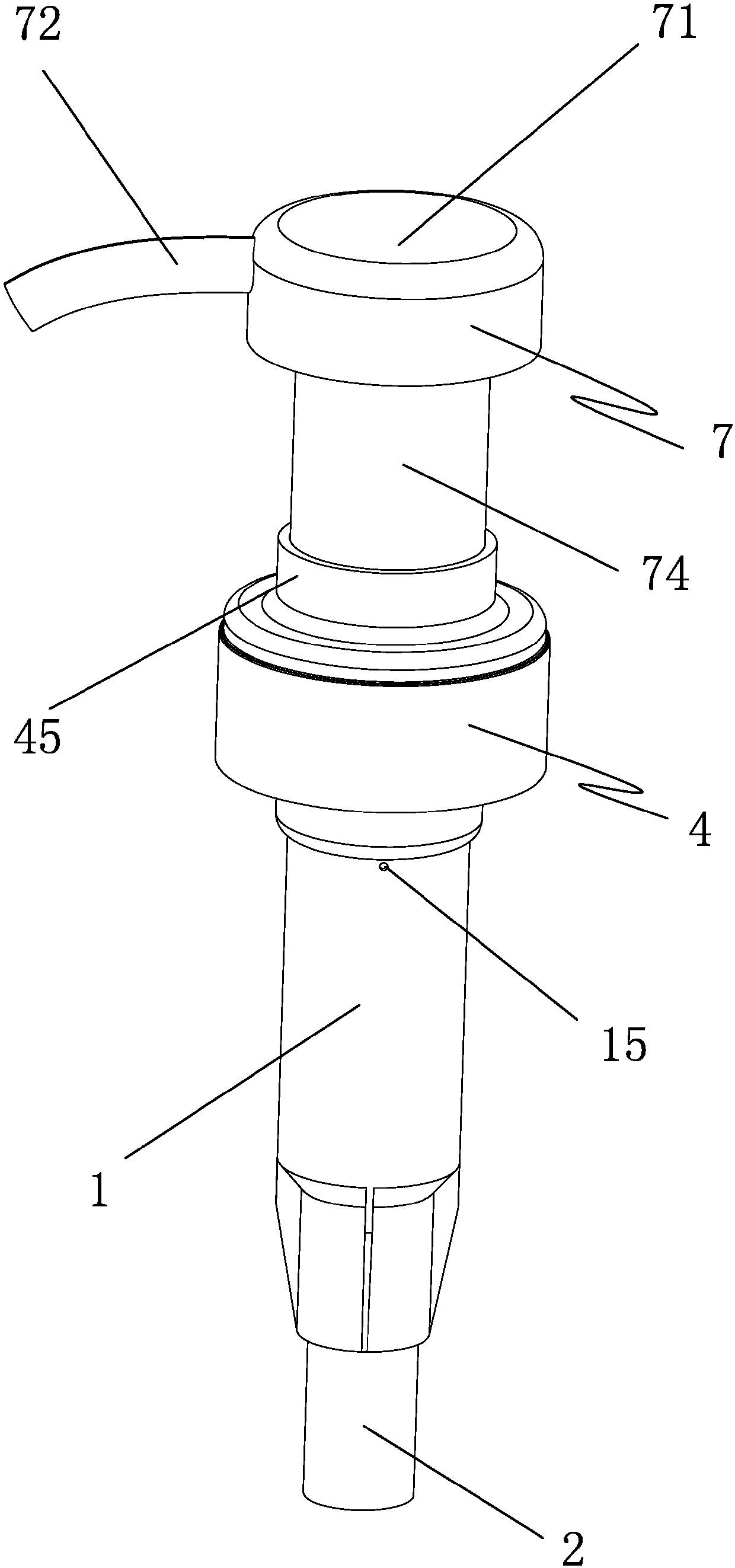

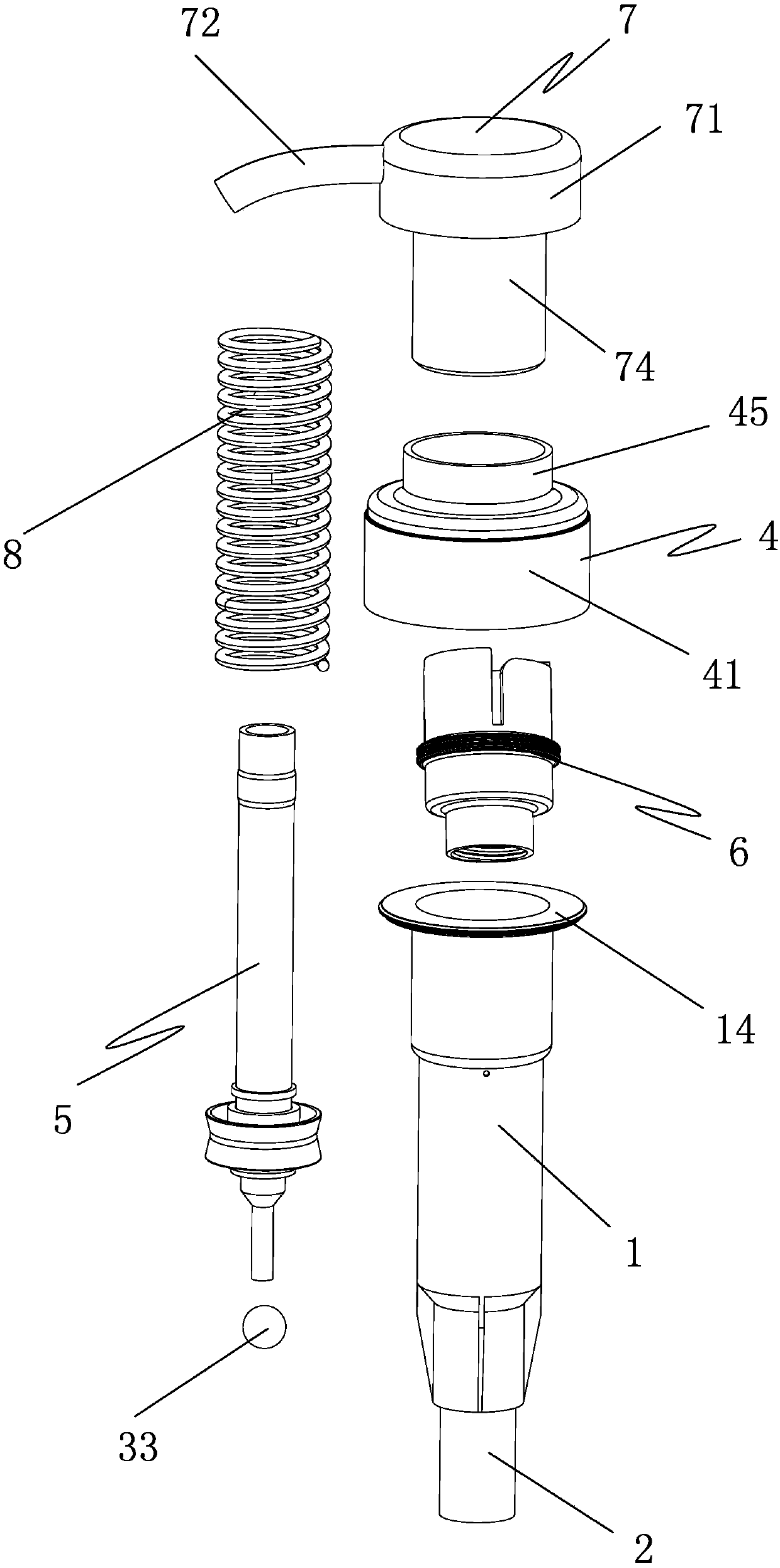

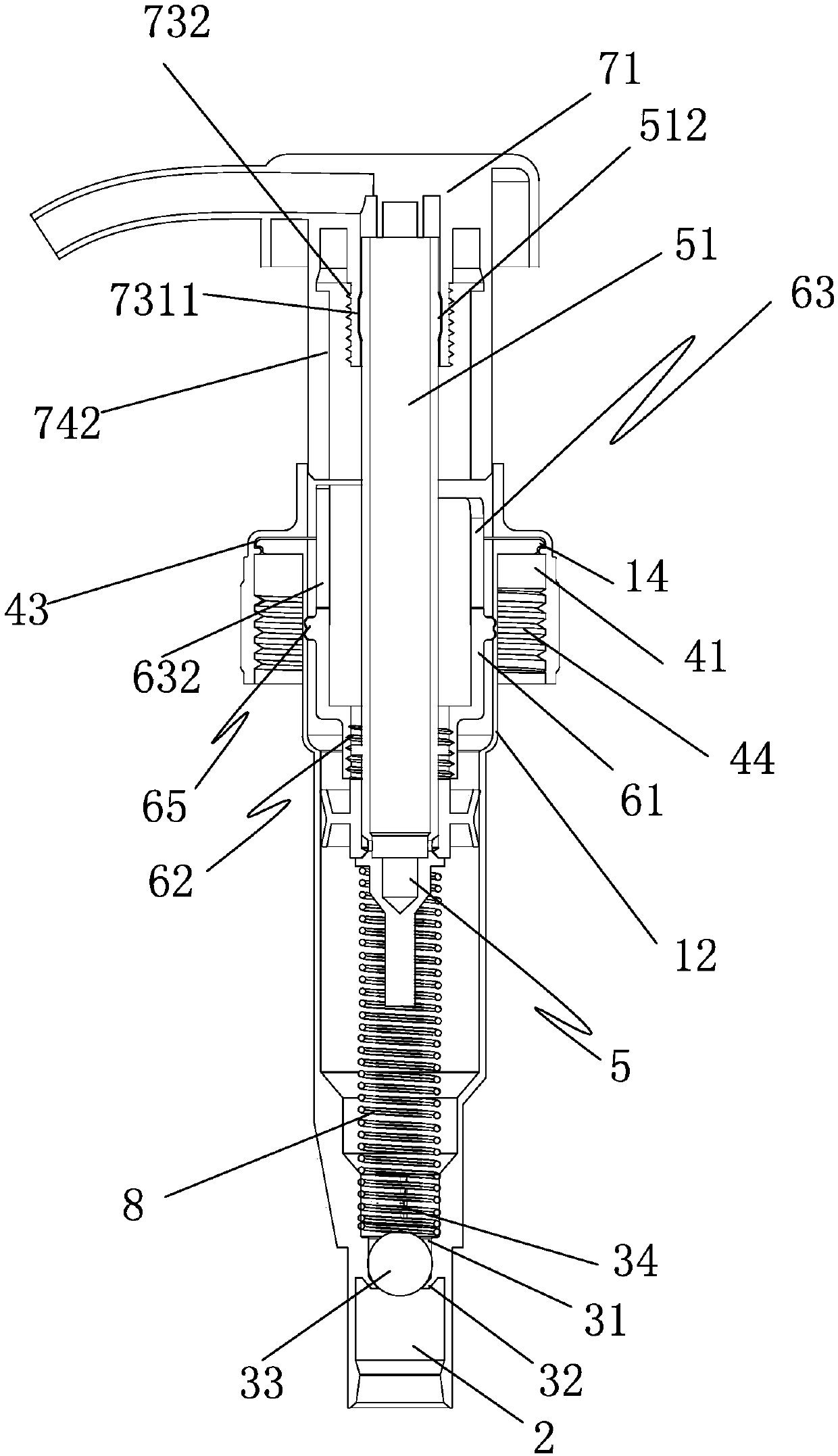

Spring-builtin standard self-locking and thread lock liquid distribution pump

ActiveCN105947389ARealize standardized productionEasy to produceClosuresLiquid spraying apparatusPump chamberEngineering

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

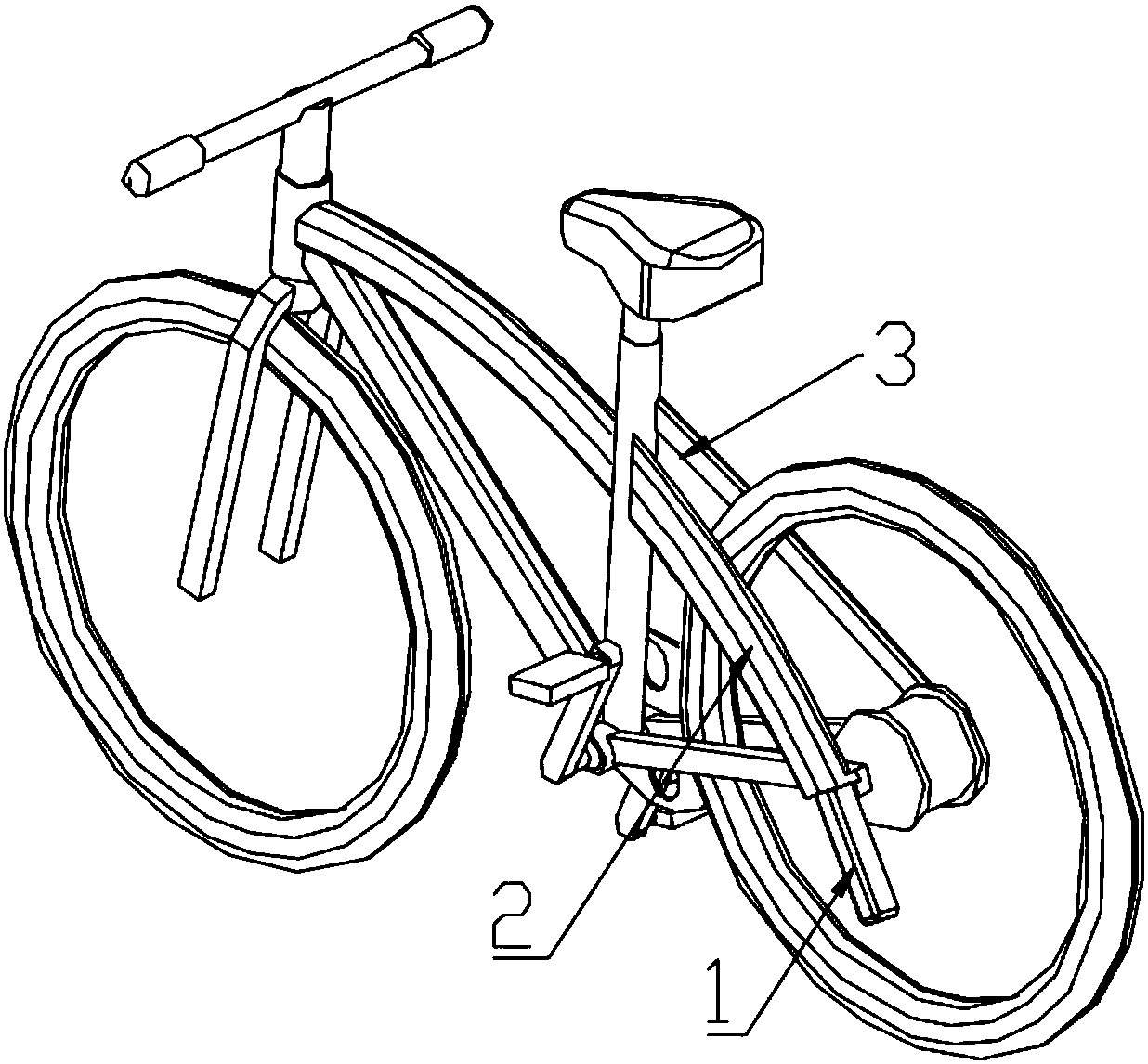

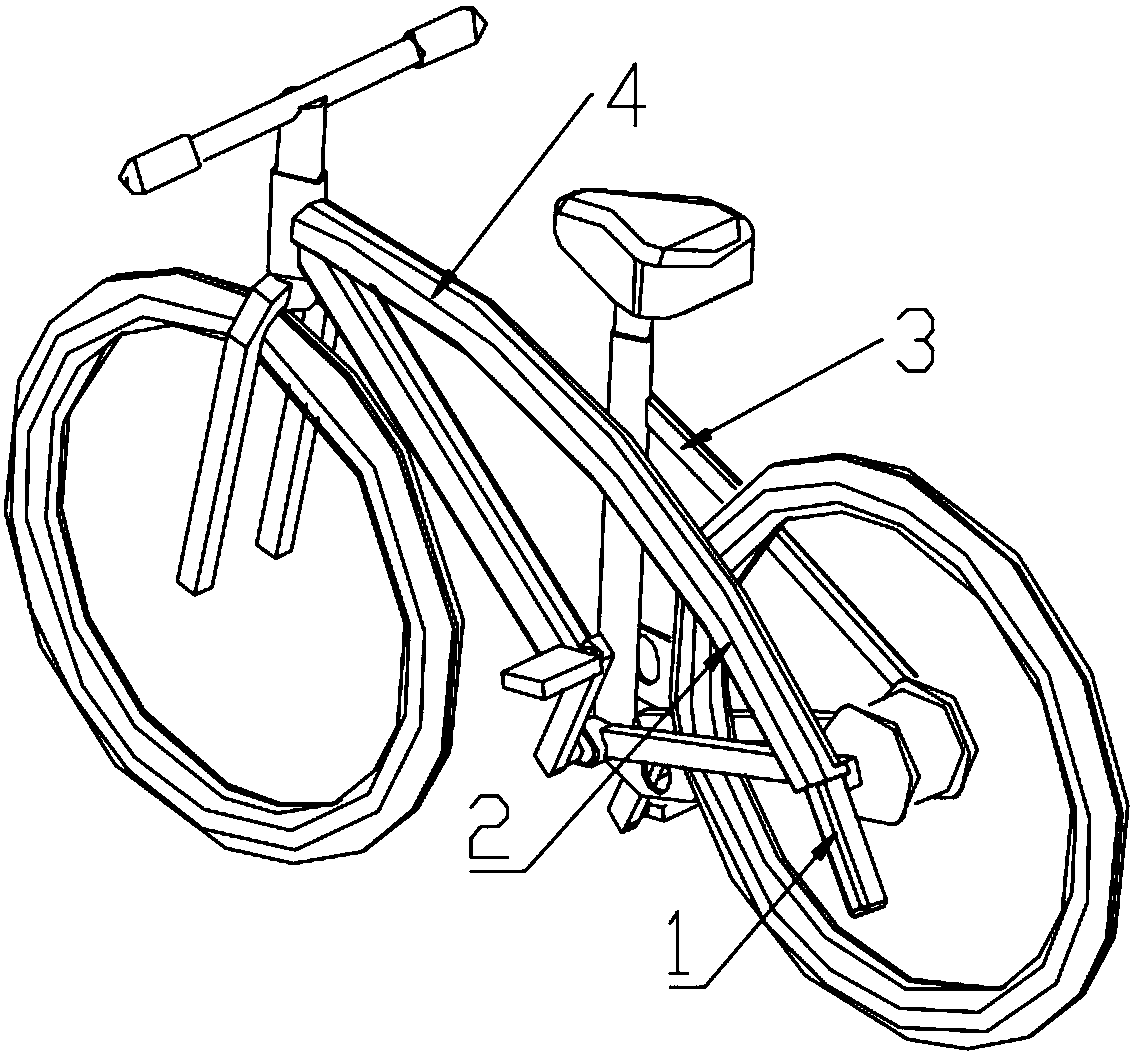

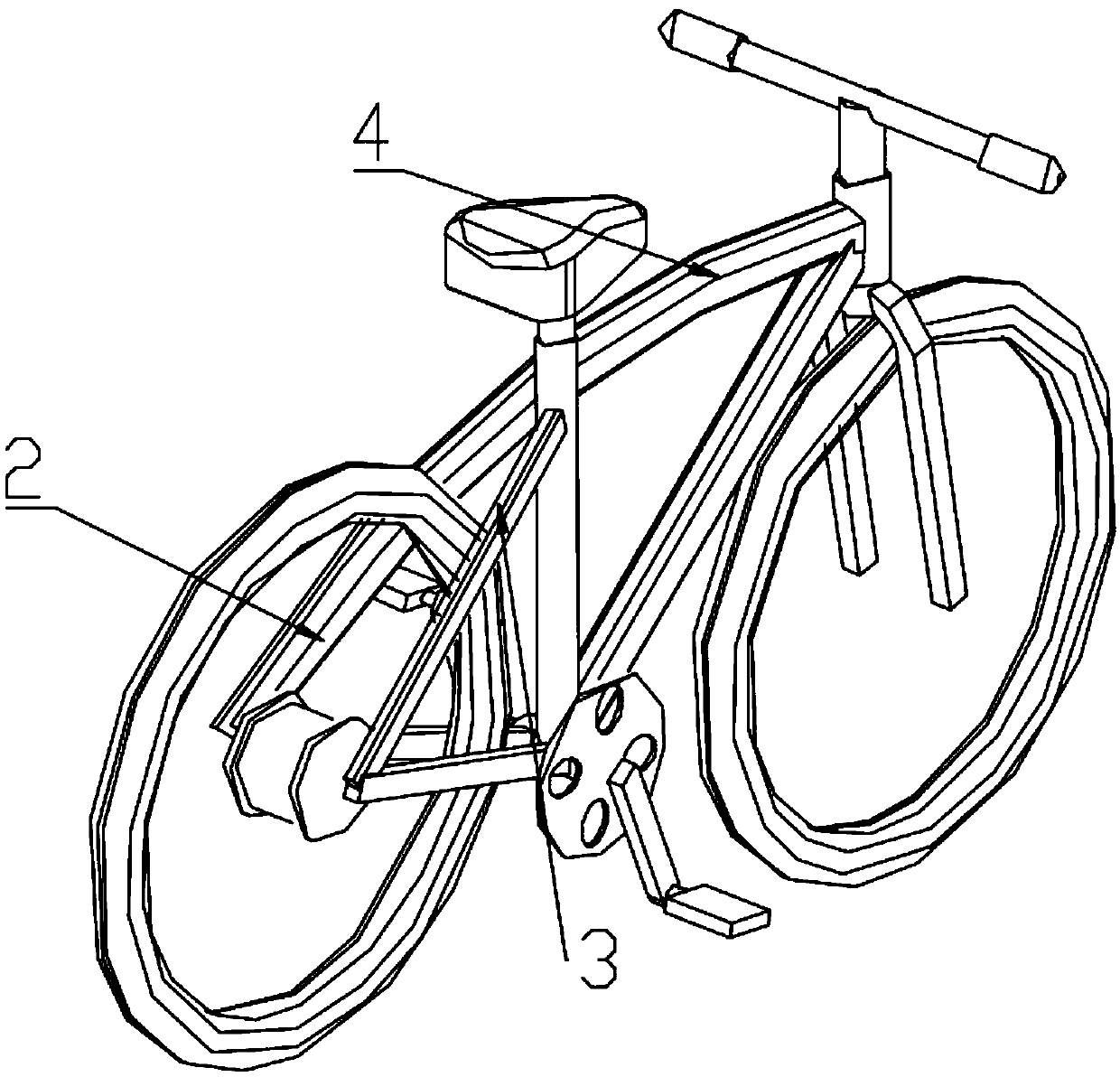

Electric bicycle with internal batteries

InactiveCN107672719AImplement built-inIncrease storage spaceMotorcyclesRider propulsionElectrical batteryEmbedded system

The invention discloses an electric bicycle with internal batteries. The electric bicycle includes the batteries, a left back fork and a right back fork. The electric bicycle is characterized in thatat least one hollow cavity is installed in the left back fork or the right back fork; the batteries are one or two and are installed in the hollow cavities; in addition, the electric bicycle also includes an upper pipe; and the upper pipe, the left back fork or the right back fork are in an integrated hollow structure. According to the electric bicycle with the internal batteries, by installing the hollow cavities in the left back fork and the right back fork, the batteries are internally installed. The protection of the batteries is achieved and the accident that battery electrodes are accidentally touched when riding is prevented. Meanwhile, transmitting of battery heat is achieved; heat dissipation of the battery is achieved; in addition, through the installation of the integrated hollow structure of the upper pipe, the left back fork or the right back fork, the accommodation space of the batteries is increased, that is, the capacity of the batteries is increased and the cruising ability of the electric bicycle is improved.

Owner:TAICANG ZHETAITIAN PROD DESIGN

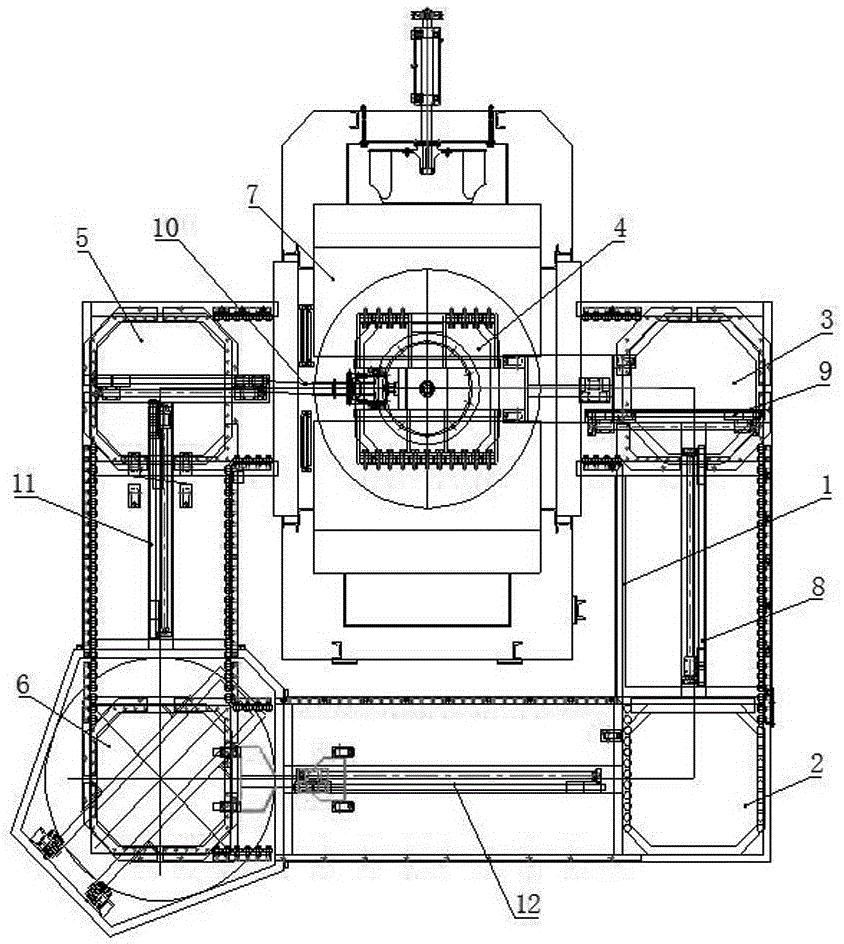

Compact type rotation molding production line

The invention relates to a compact type rotation molding production line. The compact type rotation molding production line comprises a machine frame and a rotation molding mold, and is characterized in that a manual operation station, a waiting station, a rotation molding station, a discharging and reversing station, and a cooling station are arranged on the machine frame in rectangular layout; the manual operation station, the waiting station, the discharging and reversing station, and the cooling station are sequentially distributed at four corners of the rectangle; the rotation molding station is arranged between the waiting station and the discharging and reversing station; and a rotation molding machine is mounted at the rotation molding station. The compact type rotation molding production line disclosed by the invention has the advantages that the rectangular layout is adopted; the arrangement of the stations is reasonable; the rotation molding process route is realized; and besides, the structure is compact, and the process route is reasonable, so that the shortening of a production cycle is facilitated.

Owner:南通智晶塑料制品有限公司

Point type optical fiber smoke-sensing fire detector with built-in spectroscopic optical fiber as signal indication

PendingCN110068532AShorten the lengthImplement detectionScattering properties measurementsFiberFire detector

The invention discloses a point type optical fiber smoke-sensing fire detector with a built-in spectroscopic optical fiber as signal indication. The point type optical fiber smoke-sensing fire detector with a built-in spectroscopic optical fiber as the signal indication comprises a base shell, a bottom shell and a sensing box; wherein in the sensing box, one end of the box side body is connected to the box top plate, and the other end of the box side body is connected to the base bottom plate in the base shell; a smoke guiding port is opened in the middle of the base bottom plate; in the innercavity of the box, a clamping spacer region between an incident fiber clamping portion and a receiving fiber clamping portion is connected with a smoke inlet in the bottom shell through the smoke guiding port and a bottom shell cavity; an incident / receiving fiber clamping groove is separately formed in the inside of the incident / receiving fiber clamping portion; the depth of the incident fiber clamping groove is smaller than the depth of the receiving fiber clamping groove; the receiving fiber clamping groove includes a receiving fiber clamping cavity and a signal indicating fiber clamping cavity which are communicated; and a base shell signal hole communicated with the signal indicating fiber clamping cavity is formed on the base bottom plate. The design can not only realize the smoke sensing of the optical fiber, but also realize the built-in effect of the signal indicating fiber and reduce the application cost.

Owner:深圳晶点光科有限公司

Weaving machine and preparation method for conductive fabric

ActiveCN104264346ASimple structureReduce consumptionFibre typesAuxillary apparatusFiberIn situ polymerization

The invention discloses a weaving machine and a preparation method for conductive fabric. An aniline gas generator and a plasma polymerization reactor are arranged between a weft accumulator and a weft guide device of the weaving machine in sequence, and fiber to be weaved passes through the aniline gas generator and the plasma polymerization reactor in sequence from the weft accumulator and is led out from the weft guide device. The preparation method for the conductive fabric includes that the fiber to be weaved is performed with polymerization reaction under a plasma condition after absorbing aniline gas, and the conductive fiber is weaved with warps to obtain the conductive fabric. According to the weaving machine, the aniline gas generator and the plasma polymerization reactor are arranged between the weft accumulator and weft guide device, the fiber to be weaved firstly adsorbs aniline through the aniline gas generator, and then the aniline is performed with in situ polymerization in the plasma polymerization reactor to form a poly-aniline conductive coat on the surface of the fiber to be weaved to obtain the conductive fiber; the conductive fiber serves as weft yarns, and the weft yarns are weaved with warps to obtain the conductive fiber. The weaving machine and the preparation method for the conductive fabric are capable of integrating the fiber modification and fabric production.

Owner:苏州高飞纺织有限公司

LED light source bioreactor

ActiveCN101629142BReduce volumeIncrease brightnessPhotobioreactorsTissue/virus culture apparatusTrombe wallPhotobioreactor

Owner:王科

Built-in thread opening processing die and manufacturing process of internal thread high-borosilicate glass cup

PendingCN109809680AEasy to take outImplement built-inGlass reforming apparatusEngineeringScrew thread

The invention relates to the field of glass cup processing, and particularly discloses a built-in thread opening processing die. The built-in thread opening processing die comprises an installation seat, a telescopic assembly, a first assembly and a second assembly; the outer side of the first assembly and the outer side of the second assembly are provided with concentric cambered surfaces, and the concentric cambered surfaces are connected in order to form a cylindrical structure; and raised lines matched with slideways are arranged on the positions, corresponding to the slideways, on the first assembly and the second assembly. A manufacturing process adopting the built-in thread opening processing die to process an internal thread high-borosilicate glass cup includes the steps that a glass pipe is selected, and the glass pipe is cut into a pipe blank with the required length through a pipe blasting machine; openings at the two ends of the pipe blank are burnt through flames, the pipeblank is subjected to bottom sealing through a bottom sealing machine and cleaned; the cleaned pipe blank is subjected to in-opening thread processing; and then the pipe blank is put into an annealing furnace to be annealed. According to the high-borosilicate glass cup with an internal thread, the cold and hot temperature difference reaches 150 DEG C, during use by people, lips can no longer touch uneven threads, and the attractiveness, health, fashion, safety of high-borosilicate glass and the taste of water are better experienced.

Owner:HEBEI MSD GLASS TECH CO LTD

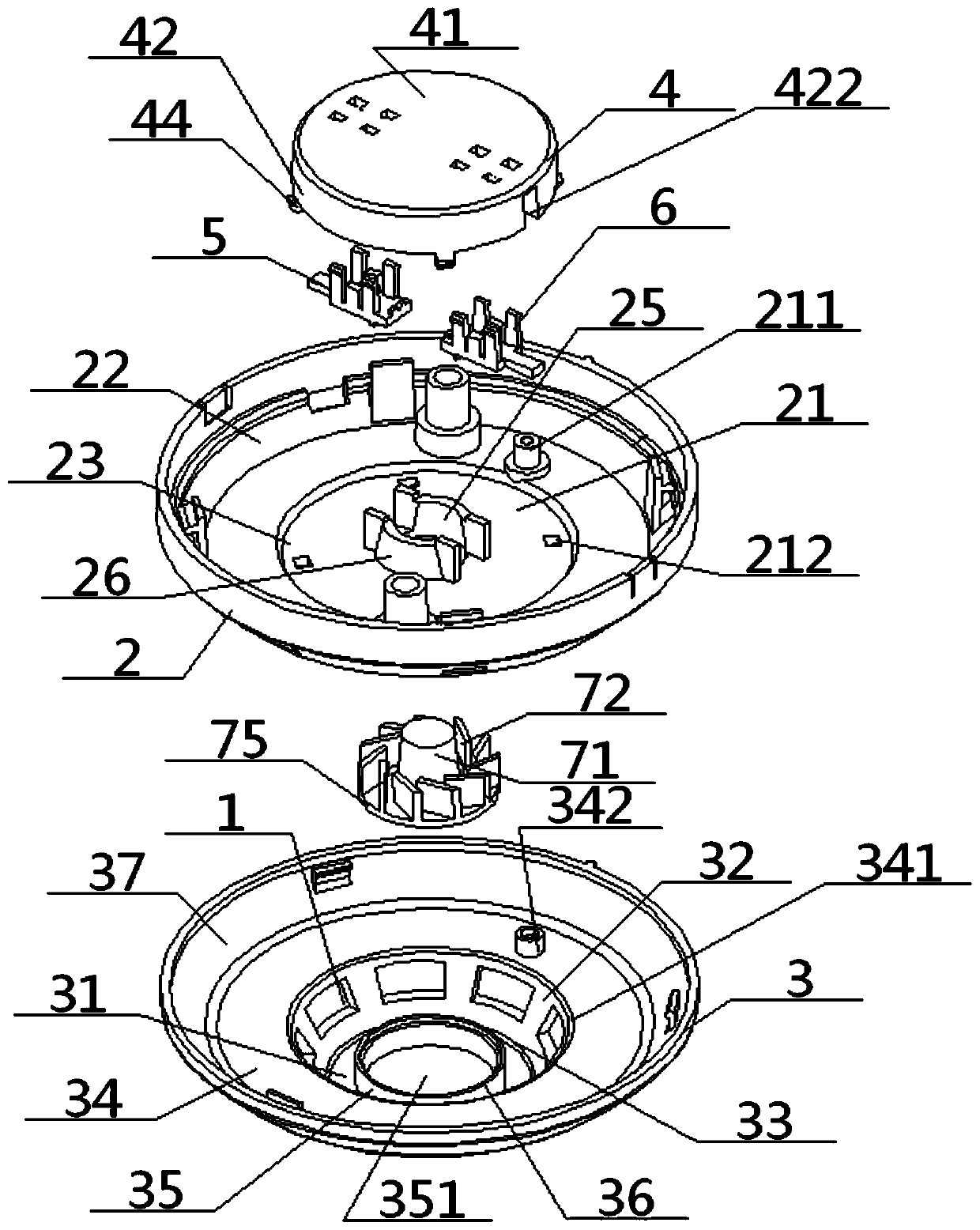

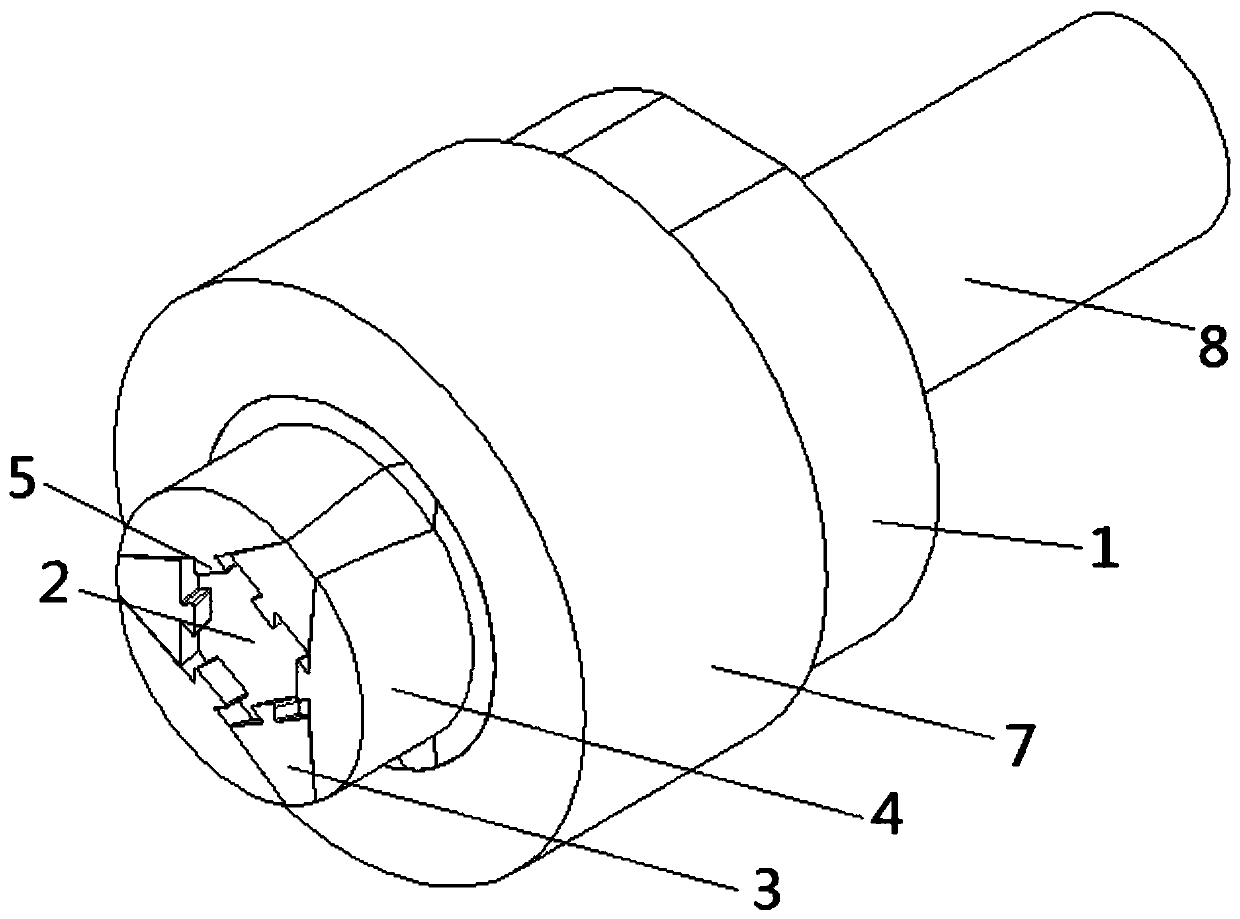

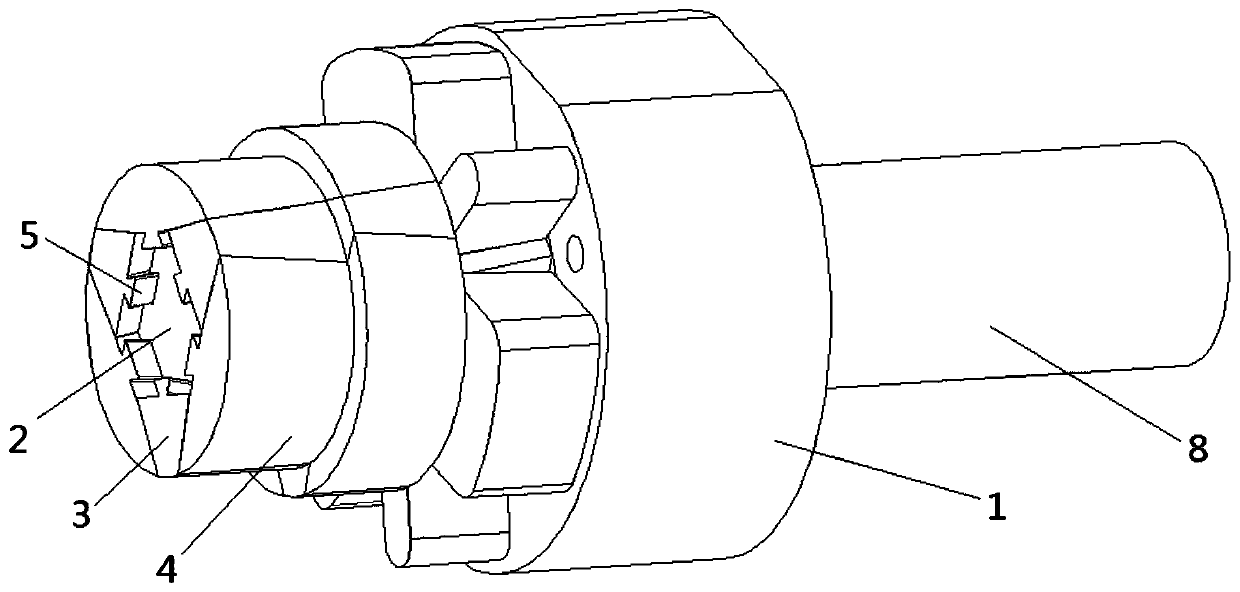

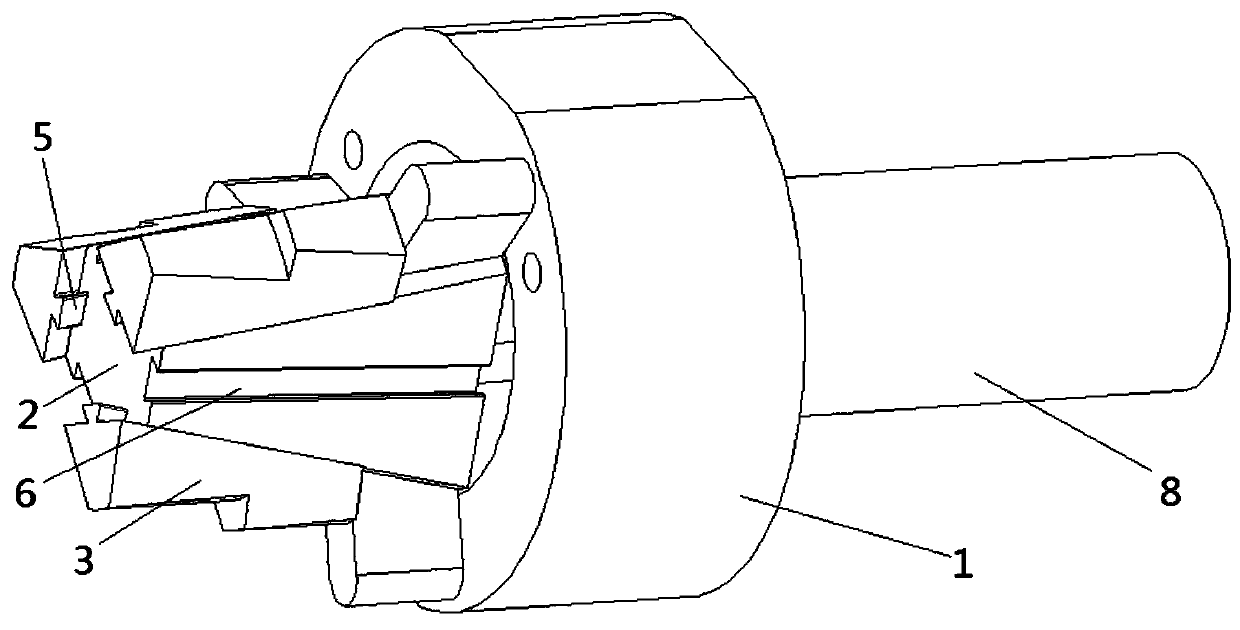

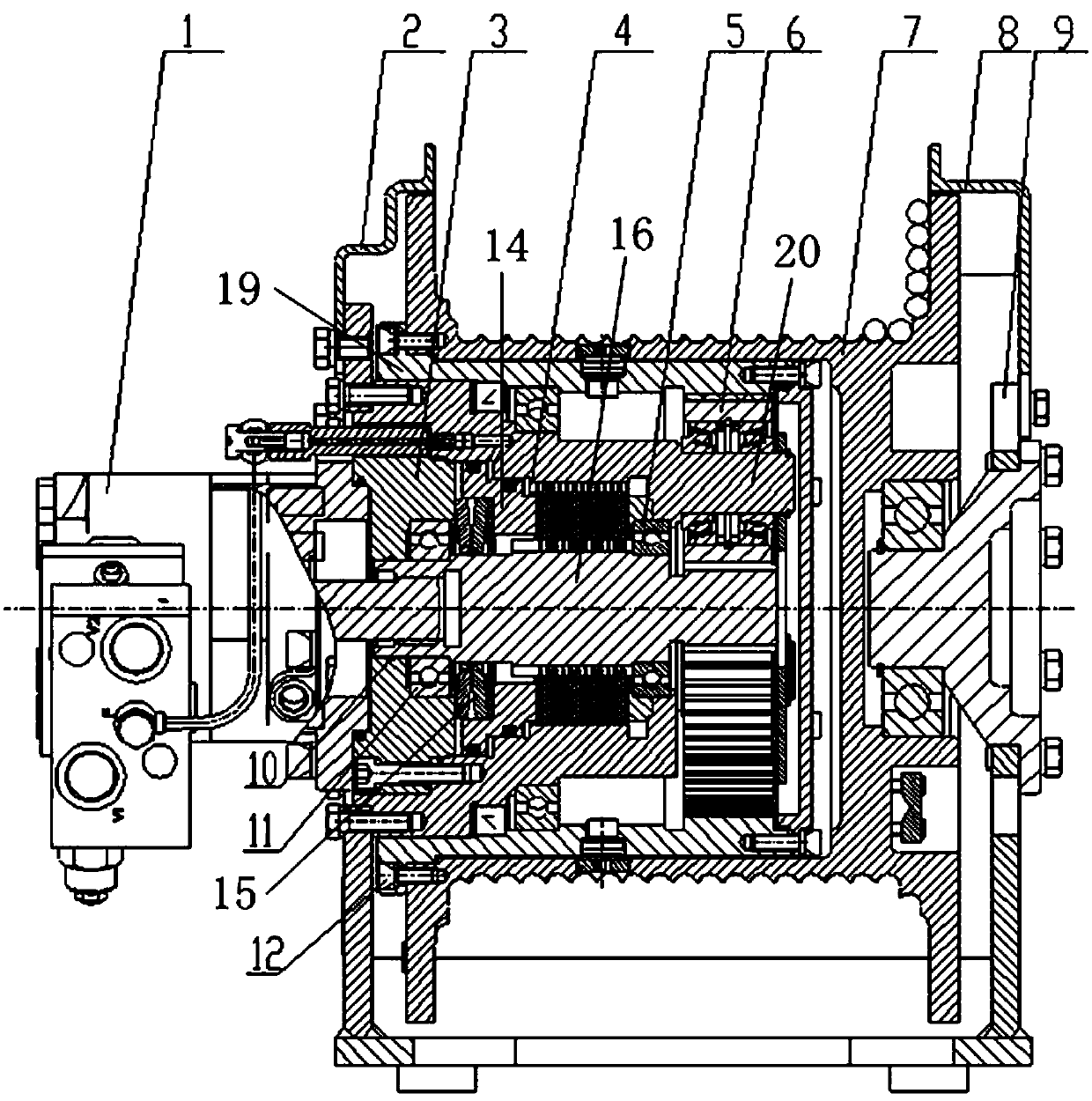

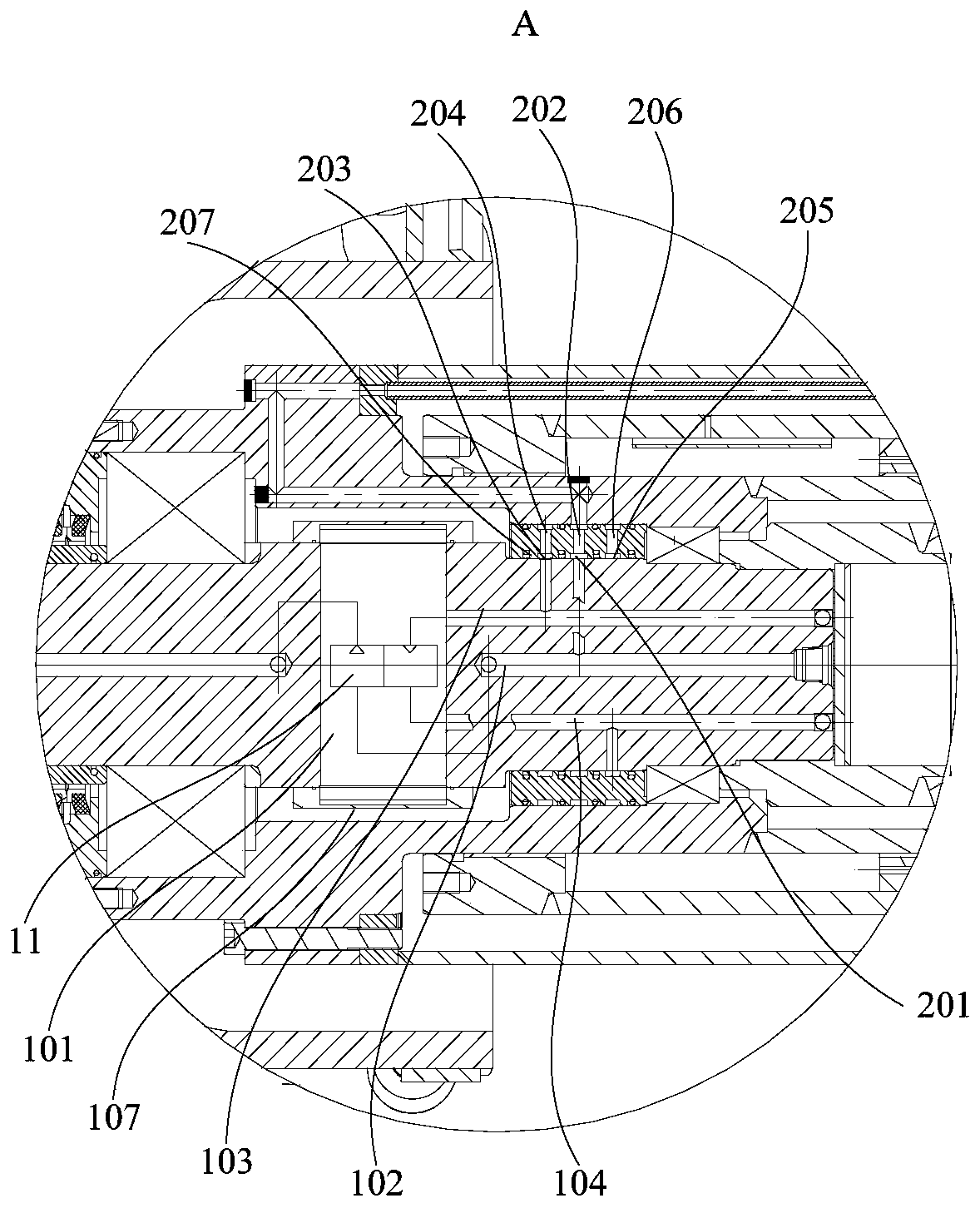

Built-in hydraulic winch

PendingCN110451413AShorten the axial structural lengthImplement built-inWinding mechanismsHydraulic motorControl engineering

The invention belongs to the technical field of hydraulic winches, and particularly relates to a built-in hydraulic winch. The built-in hydraulic winch comprises a hydraulic motor, a brake, a planet decelerating mechanism, a coiling block and a support; the hydraulic motor is fixedly connected to a motor connecting disc, the motor connecting disc is fixed into a brake core inner cavity of the brake, a brake core is fixedly connected with the support, the motor connecting disc is located on the inner side of the support, an output shaft of the hydraulic motor is in transmission connection witha wheel shaft of a sun wheel of the plane decelerating mechanism, a gear ring of the planet decelerating mechanism is fixedly connected with the coiling block, and the end, away from the hydraulic motor, of the coiling block and the support are rotatably supported. According to the technical scheme, the length of an axial structure can be shortened, the hydraulic motor can be built in the winch, meanwhile, due to reasonable arranging of a planet carrier, the gear ring and the coiling block, the inner space of the winch can be saved, meanwhile, the premise is provided for the built-in type structure of the winch, process of the manufacturing can be greatly improved, and cost is reduced.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE

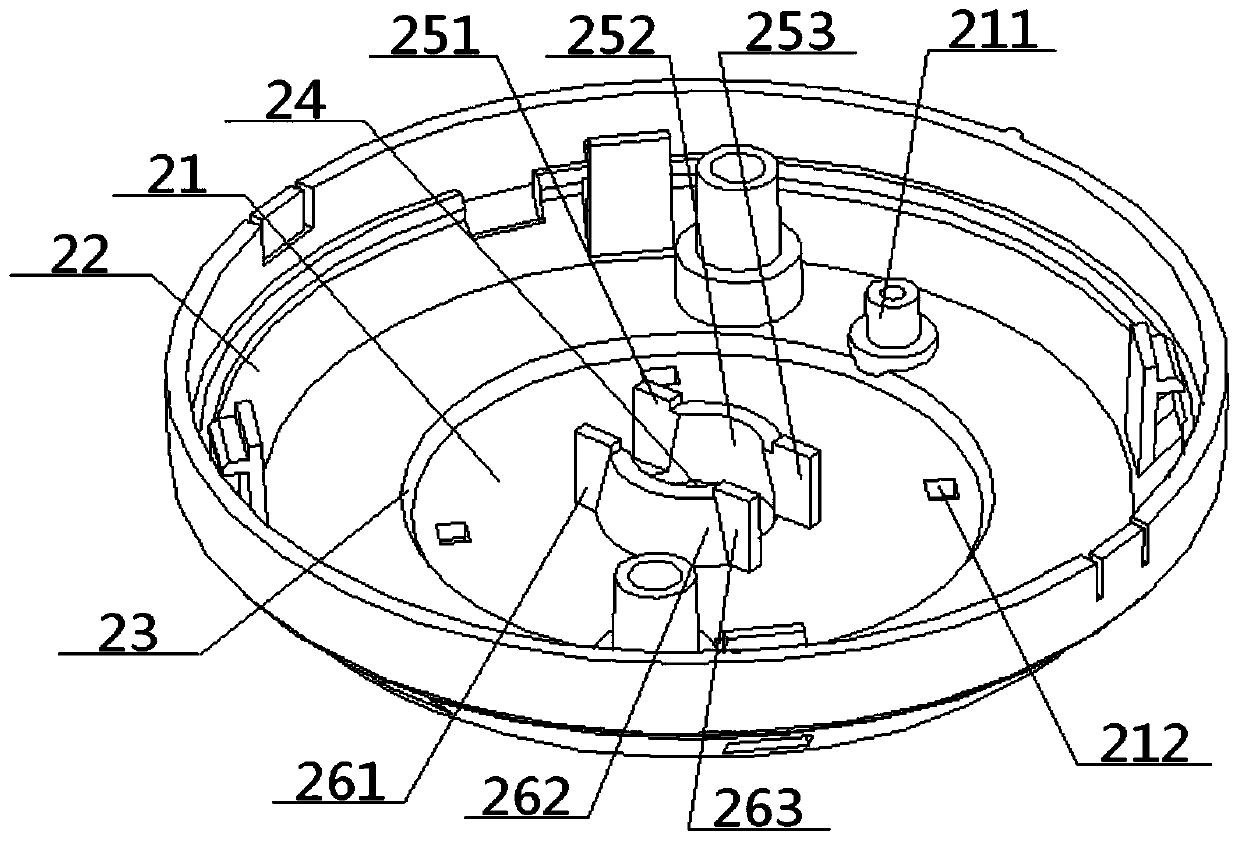

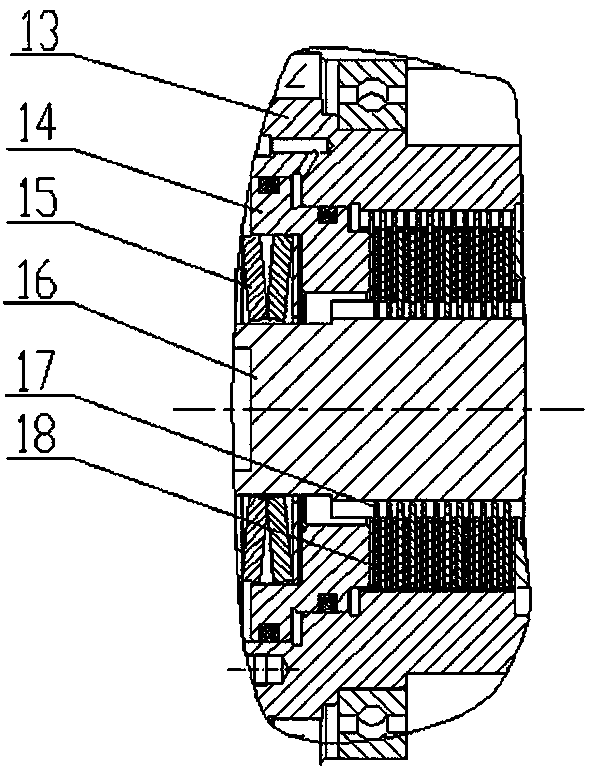

Complicated control of high-precision bus-type digital micro-servo motor and its application

ActiveCN108494177BReduce floor areaImplement built-inAssociation with control/drive circuitsMechanical energy handlingBusDirect current

The invention provides a micro servo motor and an application thereof; the micro servo motor comprises a direct current motor, a variable gear group, an output shaft, an angular sensor and a control panel; the control panel comprises a plurality of sub control panels; the sub control panels are stacked to form a multilayer structure; the sub control panels are connected through electrical connecting pieces to realize signal transmission; the micro servo motor also comprises an interface plate; the interface plate, the multilayer structure and the angular sensor are stacked in sequence; the interface plate is connected with the corresponding sub control panels through electrical connecting pieces to realize signal transmission; the angular sensor is connected with the output shaft; the direct current motor is in transmission connection with the output shaft through the variable gear group; and the interface plate and the multilayer structure are both arranged on the side surface of thedirect current motor.

Owner:谜米机器人自动化(上海)有限公司

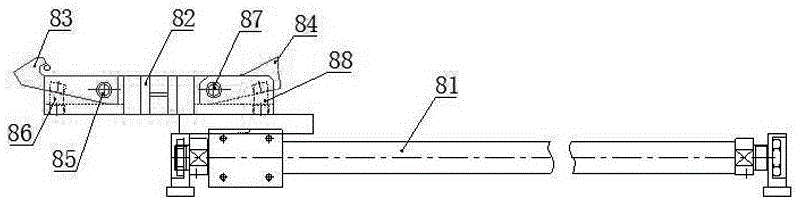

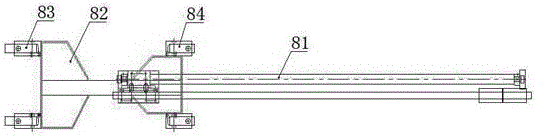

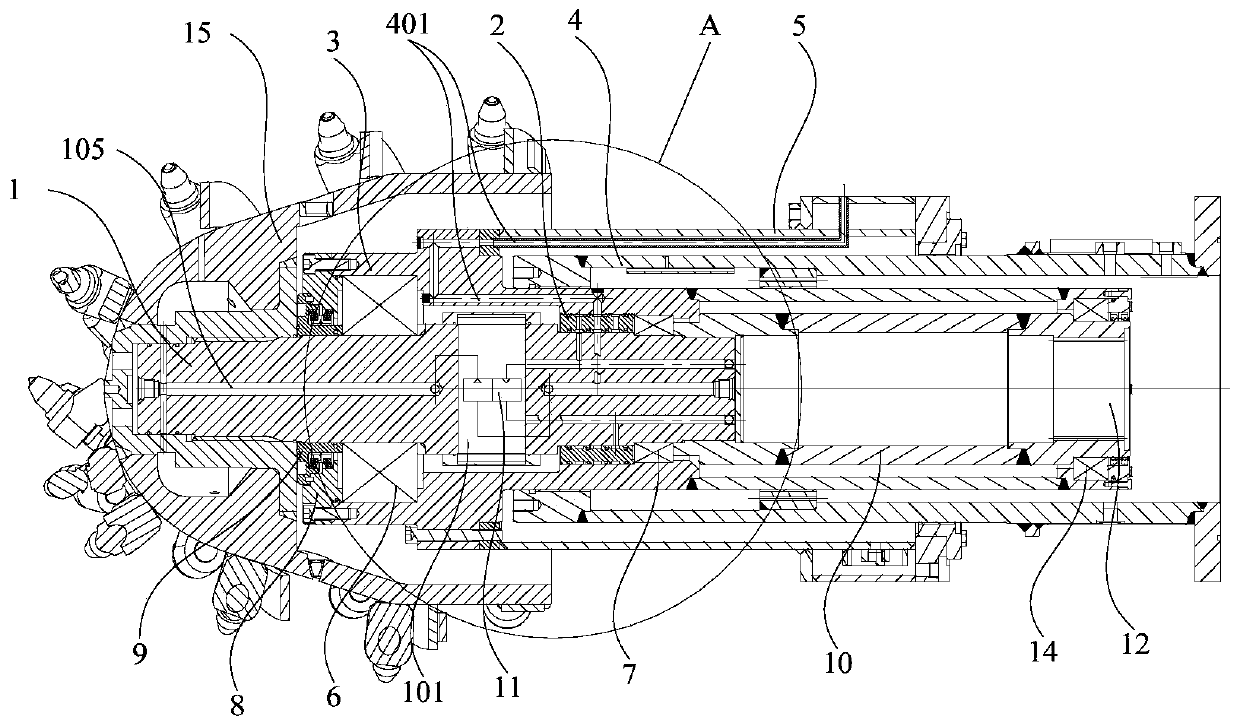

Inner atomizing type telescopic cutting mechanism and tunneling machine

PendingCN111322067AImproves sealing reliabilityExtended service lifeSlitting machinesCutting machinesEngineeringPhysics

The invention relates to the technical field of tunneling machines, in particular to an inner atomizing type telescopic cutting mechanism and a tunneling machine. According to the inner atomizing typetelescopic cutting mechanism, an installing cavity for containing a water pump is formed in a cutting head shaft, and accordingly inner arrangement of the water pump is achieved. The cutting head shaft and a seal sleeve are matched to form a water inlet channel for supplying water to the water pump, and a rotation seal for low-pressure water inflow is formed at the connected position of the cutting head shaft and the seal sleeve. A static seal is formed between the high-pressure water outlet end of the internally-arranged water pump and a pressure water way of the cutting head shaft, and therefore the seal reliability of the inner atomizing type telescopic cutting mechanism can be improved, and the service life of the inner atomizing type telescopic cutting mechanism can be prolonged. Theprovided tunneling machine comprises the inner atomizing type telescopic cutting mechanism, and therefore the cutting mechanism can achieve the telescopic function, meanwhile, the seal reliability isimproved, and the service life is prolonged.

Owner:天津市汇智尘科技有限公司

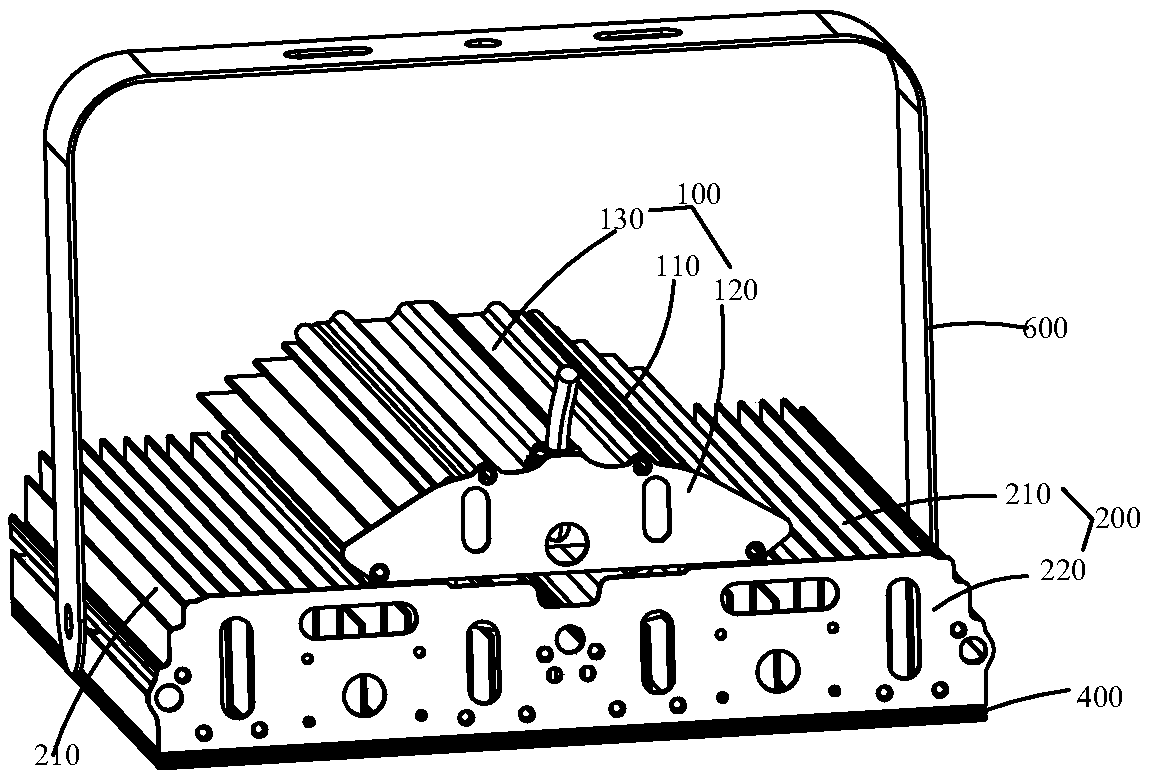

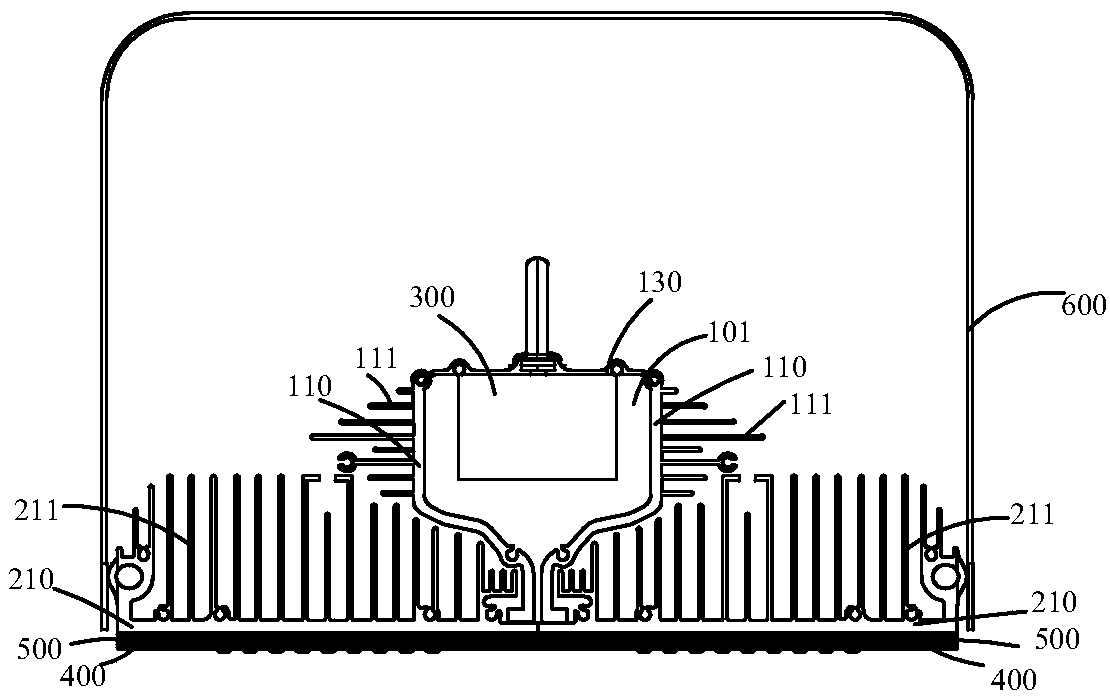

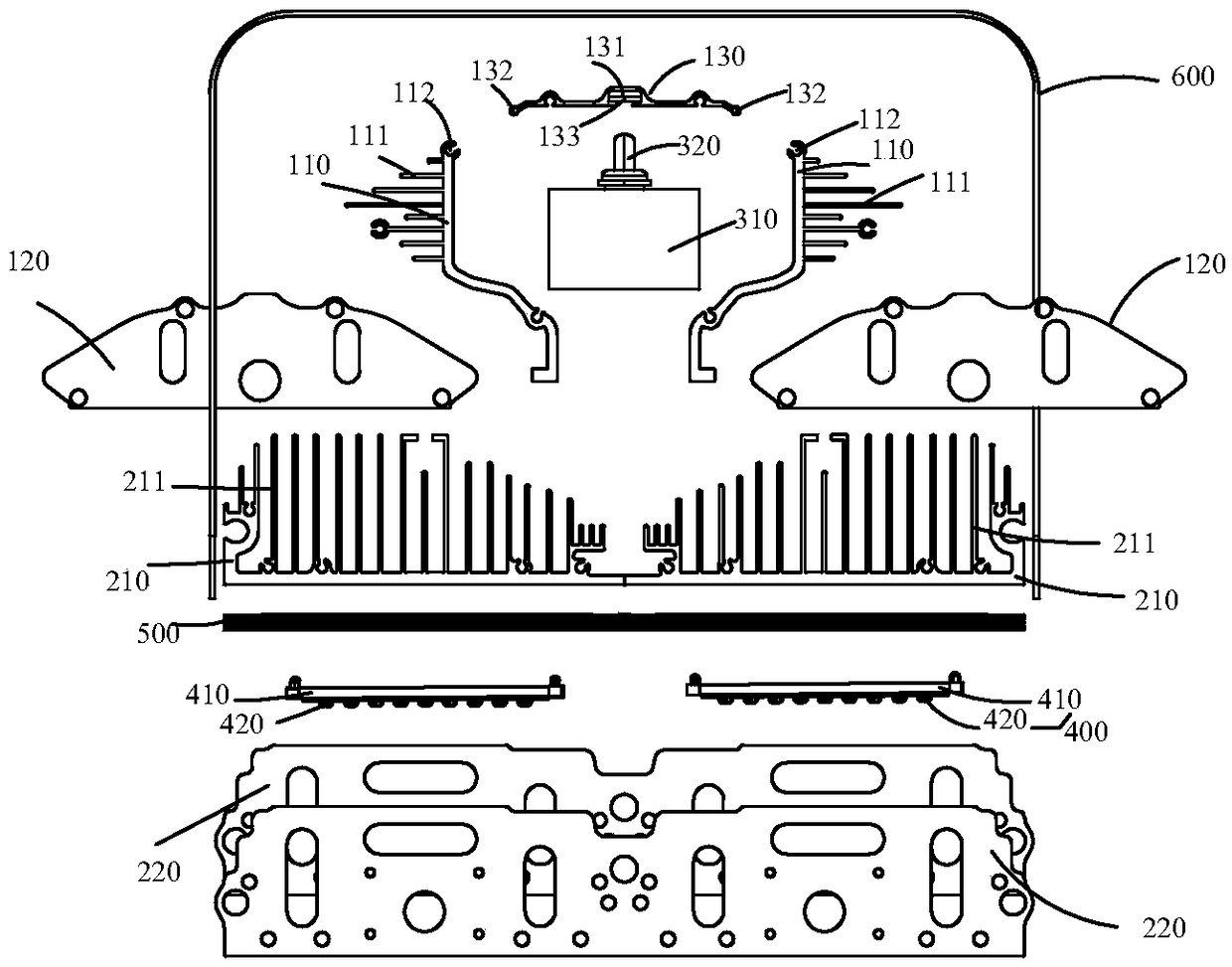

LED floodlight

PendingCN109373234ASimple structureEasy disassemblyElectric circuit arrangementsLighting heating/cooling arrangementsLight sourceWaste management

The invention relates to an LED floodlight. The LED floodlight comprises a first installation assembly and a second installation assembly. An installation cavity is defined by the first installation assembly, a power supply module is arranged in the installation cavity, the first installation assembly is connected with the second installation assembly, a light source assembly is instead on the second installation assembly, and the light source assembly is electrically connected with the power supply module. According to the LED floodlight, the power supply module is installed in the installation cavity formed by the first installation assembly, the light source assembly is installed on the second installation assembly, the first installation assembly is connected with the second installation assembly, internal installation of a power supply is achieved, and the LED floodlight is simple in structure, easy to mount and demount and high in heat dissipation efficiency.

Owner:SHENZHEN PURPLE LIGHTING TECH

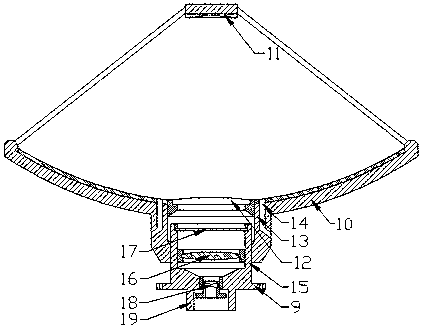

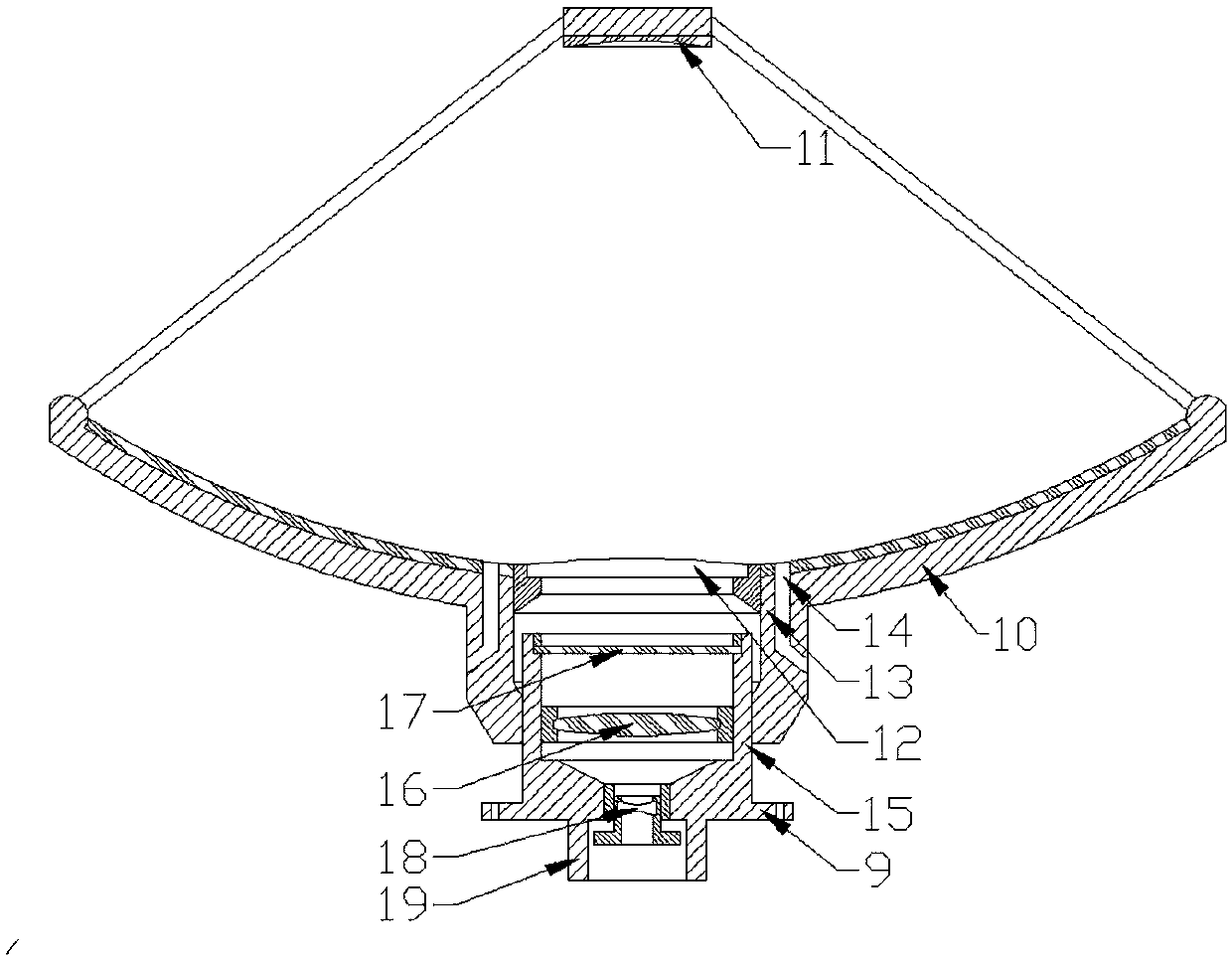

Condensation solar water heater

ActiveCN109654751AReduce weight loadRealize poolingSolar heating energyCollector thermal insulationLight guideSolar water

The invention relates to a condensation solar water heater. The water heater comprises a condensation assembly and a heating assembly, wherein the condensation assembly comprises a condensation plate,the condensation plate comprises a spherical reflecting plate, a reflecting layer is arranged on the surface of the reflecting plate, the condensation plate is connected with a retroreflector througha support, and the retroreflector is located at the sphere center position of the spherical reflecting plate; a light collecting cylinder is arranged at the center of the spherical surface of the condensation plate, a light collecting lens is arranged at one end of the light collecting cylinder, the light collecting lens is located on one face, provided with a reflecting layer, of the light collecting plate, a condensation assembly is arranged at the other end of a reflecting cylinder, the condensation assembly further comprises a light guide cylinder installed in the reflecting cylinder, a condensation lens is arranged in the light guide cylinder, and an enoscope is further arranged in the light guide cylinder; and the heating assembly comprises a connecting cylinder which is fixedly connected with the light guide cylinder, a heat collecting cylinder with an annular section is arranged in the connecting cylinder, an annular heat collecting cavity is formed in the heat collecting cylinder, and a light-transmitting hole is formed in the annular middle of the heat collecting cylinder.

Owner:JIANGSU SUNNIC SOLAR ENERGY INDAL

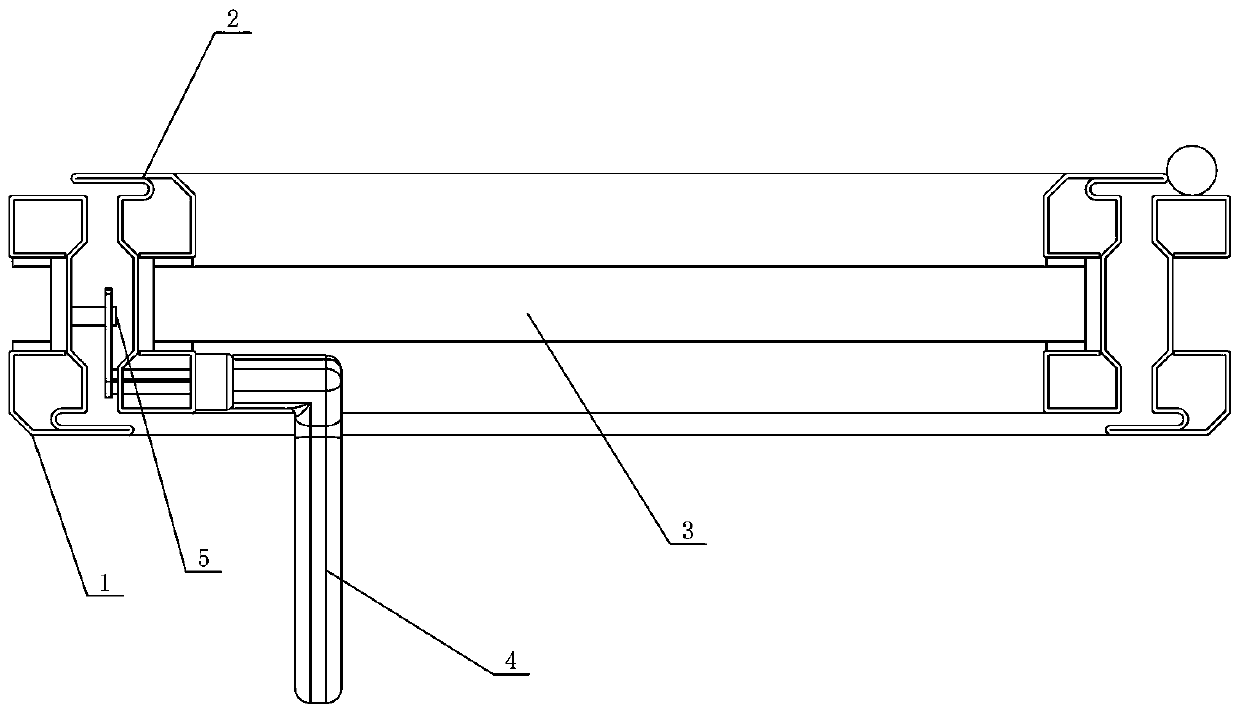

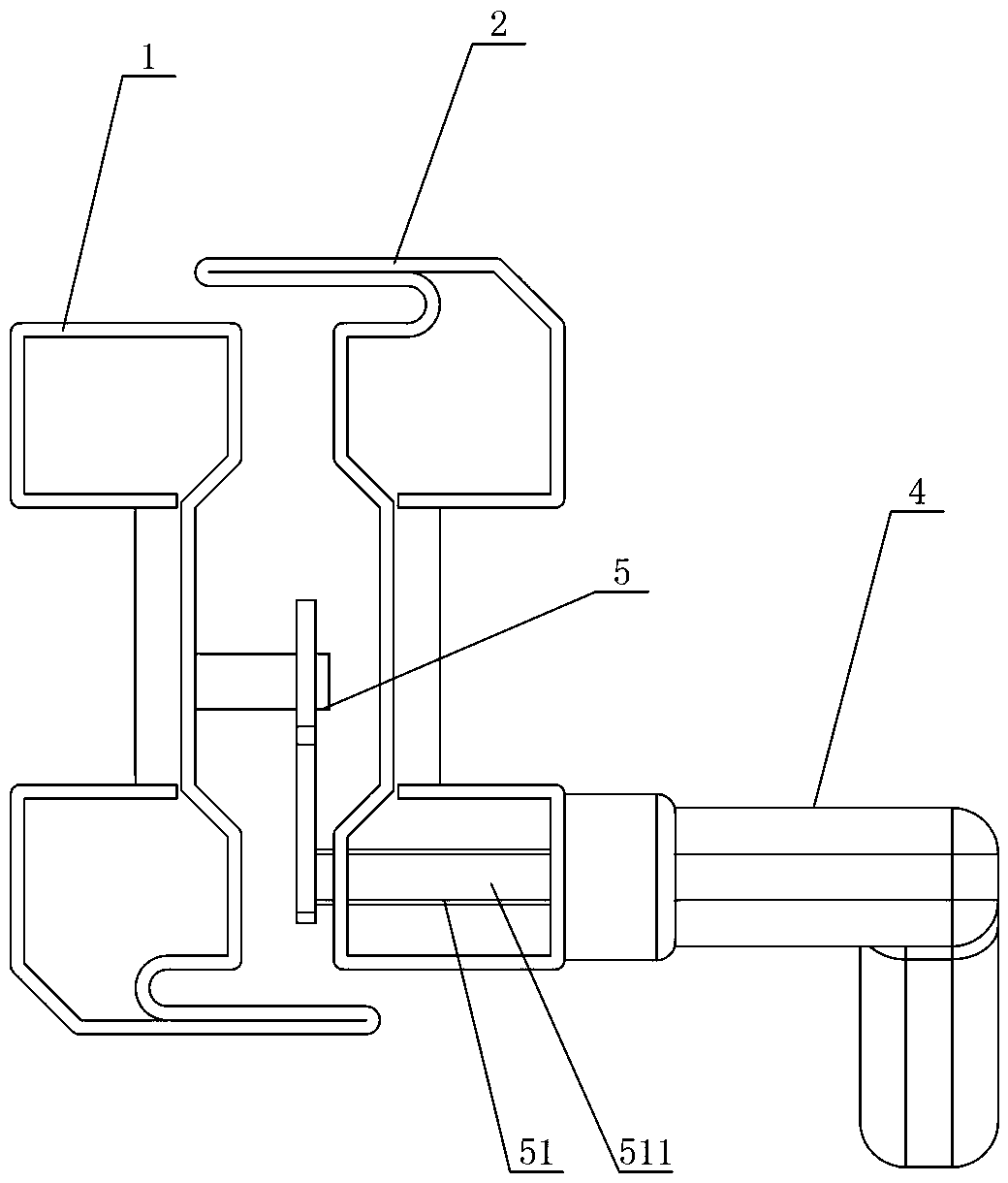

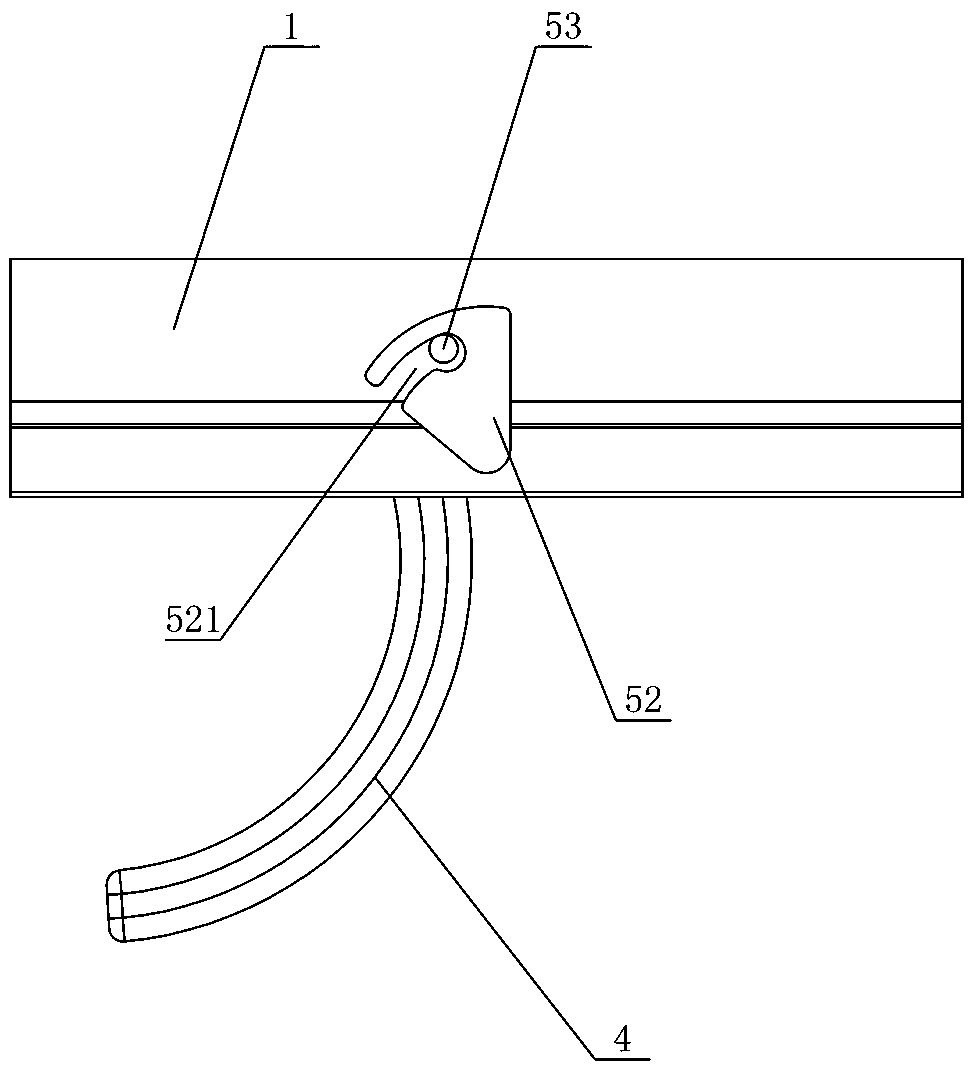

Door and window system

PendingCN109538065AImplement built-inAchieve thinningWing arrangementsHandle fastenersFixed frameEngineering

The invention discloses a door and window system. The door and window system comprises a fixing frame, a sash frame and a sash body. The sash body is fixedly arranged in the sash frame, one side of the sash frame and the fixing frame are movably hinged, the other side of the sash frame is an opening and closing side, a lock handle is arranged on the inner side edge of the opening and closing sideof the sash frame, a locking mechanism is arranged between the sash frame and the fixing frame, the locking mechanism is connected with the lock handle, when the lock handle is operated to be pulled inwards, the sash frame is closed, after the sash frame is closed and when the lock handle is operated to be lifted upwards, the locking mechanism carries out locking, after the locking mechanism carries out locking and the lock handle is operated to be pressed downwards, the locking mechanism is unlocked, and after the locking mechanism is unlocked and the lock handle is operated to be pushed outwards, the sash frame is opened. The door and window system has the advantages that the operation is easy and convenient, misoperation can be reduced, and the fineness of products can be achieved.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

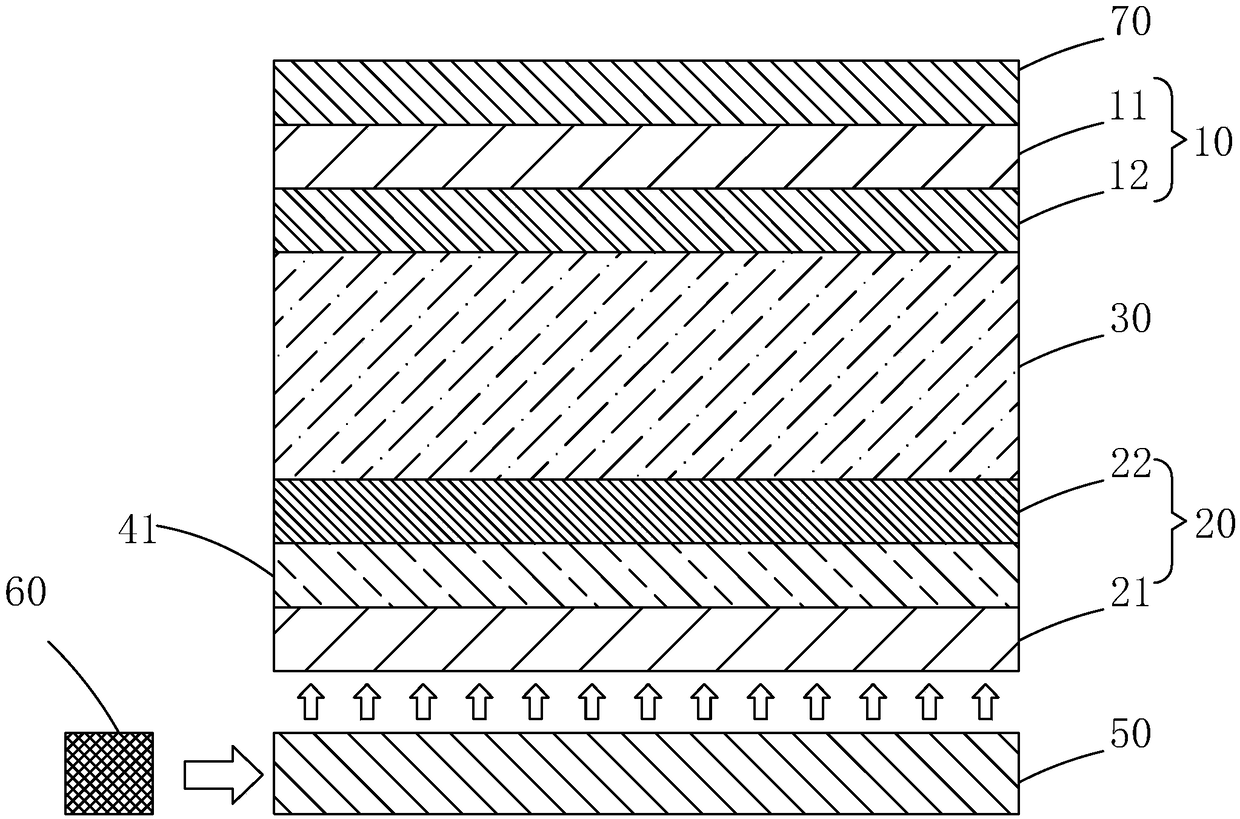

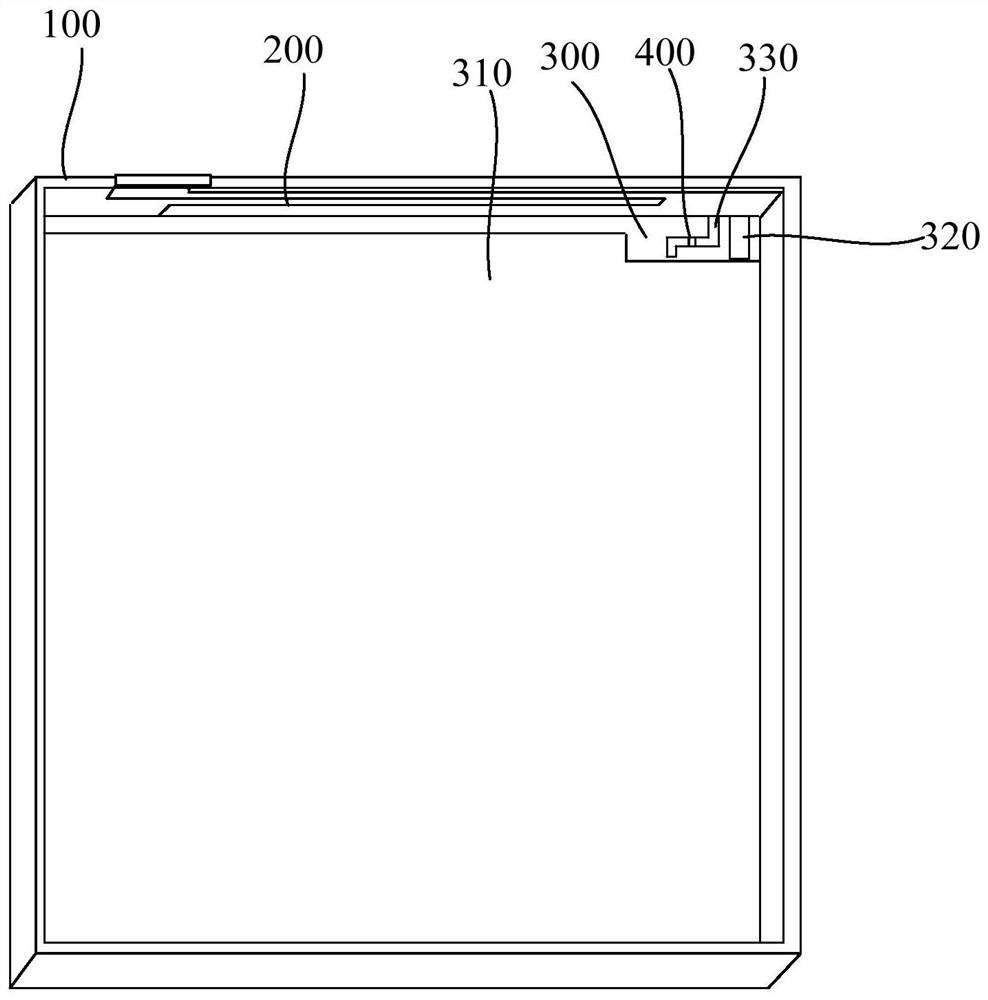

Liquid crystal display device

ActiveCN106353917BReduce thicknessImplement built-inNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display device. A dyestuff polarizing film is arranged between a TFT (thin film transistor) substrate and a TFT array layer of a TFT base plate, and is pasted on the TFT substrate through an adhesion glue layer to realize the build-in effect of the dyestuff polarizing film; the surface, leaving far away from the TFT substrate, of the dyestuff polarizing film is provided with closed first frame glue in a position near the peripheral edge position; the mutual pollution of inside materials of the liquid crystal display device and the cross section of the periphery of dyestuff polarizing film can be prevented; in addition, closed second frame glue is arranged around the peripheral edge of the dyestuff the dyestuff polarizing film; the polarizing effect influence of the cross section on the periphery of the dyestuff polarizing film due to external damp and hot environment is prevented; meanwhile, the box thickness can be effectively supported. Compared with the prior art, the liquid crystal display device has the advantages that the arrangement of a support protection film is not needed; the thickness of a liquid crystal display device is greatly reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

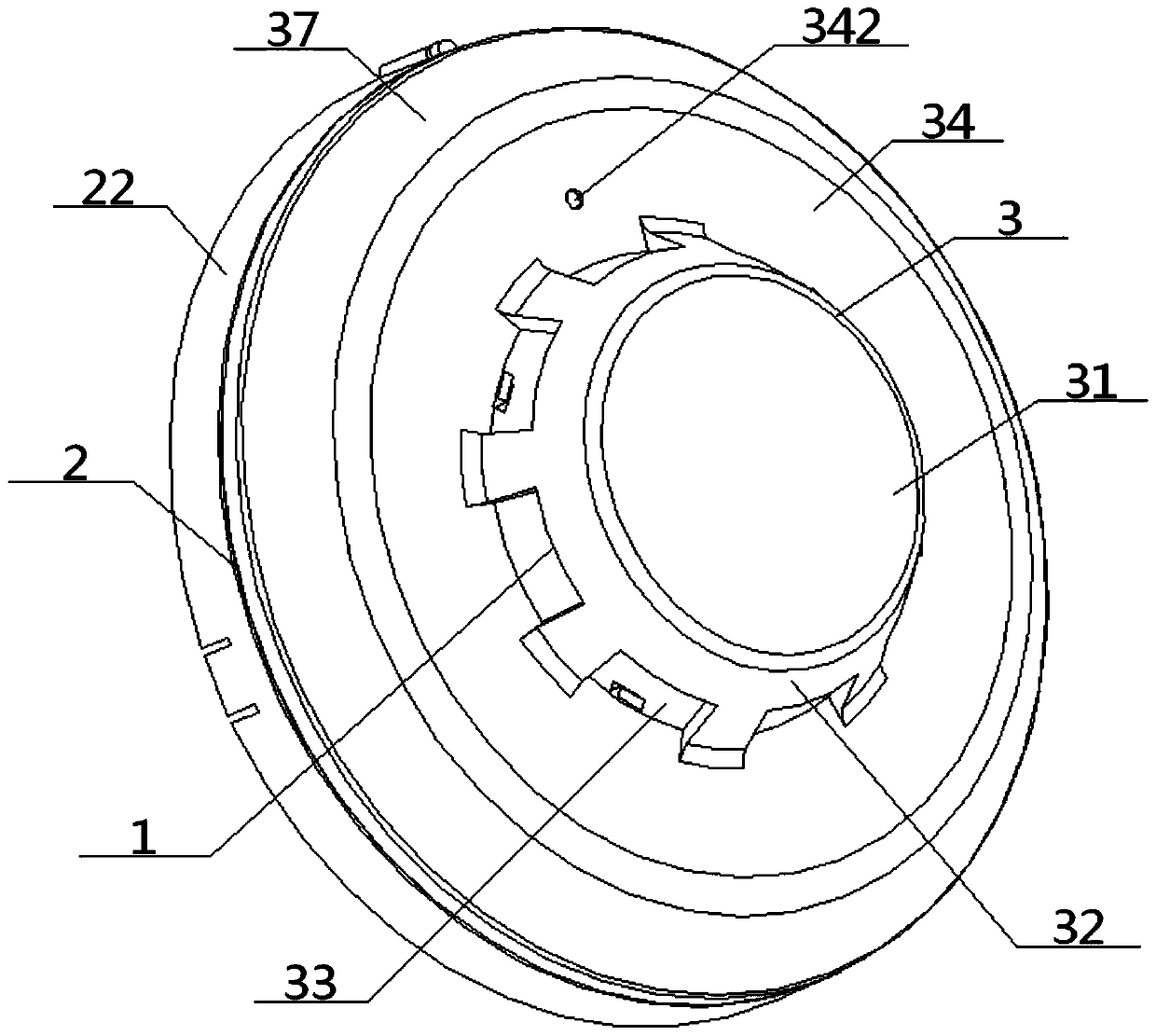

Antenna structure of intelligent wearable device and intelligent wearable device

PendingCN114094314ARealize the antenna functionAchieve ultra-thinAntenna adaptation in movable bodiesAntenna earthingsDielectric substrateMiniaturization

The invention discloses an antenna structure of intelligent wearable device and an intelligent wearable device. The intelligent wearable device antenna structure comprises an annular dielectric frame, an antenna unit arranged on the annular dielectric frame, and a dielectric substrate provided with a grounding part, a ground feeding point and a feeding point; the feeding point is connected with the feeding port of the antenna unit, and the ground feeding point is connected with the ground feeding port of the antenna unit and the grounding part. According to the invention, the antenna unit is designed on the annular dielectric frame, and the frame of the intelligent wearable device is used as an antenna dielectric carrier, so that the built-in structure of the antenna structure of the intelligent wearable device and the ultrathin and miniaturized intelligent wearable device are realized.

Owner:GEER TECH CO LTD

Concentrating solar water heater

ActiveCN106568208BReduce weight loadRealize poolingSolar heating energyCollector thermal insulationLight guideSolar water

The invention relates to a concentrating solar water heater. The concentrating solar water heater comprises a concentrating assembly and a heating assembly. The concentrating assembly comprises a concentrating panel. The concentrating panel comprises a spherical reflection plate. A light reflection layer is arranged on the surface of the reflection plate. A retrorefelctor is connected with the reflection plate through supports and located in the spherical center of the spherical reflection plate. A light collecting barrel is arranged in the spherical center of the concentrating panel. A light collecting lens is arranged at one end of the light collecting barrel and located on the face, provided with the reflection layer, of the concentrating panel. A concentrating assembly body is arranged on the other end of the light collecting barrel. The concentrating assembly further comprises a light guide barrel installed in the light collecting barrel. A concentrating lens is installed in the light guide barrel. A refractor is further arranged in the light guide barrel. The heating assembly comprises a connecting barrel fixedly connected with the light guide barrel. A heat collecting barrel with the annular section is arranged in the connecting barrel. An annular heat collecting cavity is formed in the heat collecting barrel. Light holes are formed in the annular middle portion of the heat collecting barrel.

Owner:JIANGSU SUNNIC SOLAR ENERGY INDAL

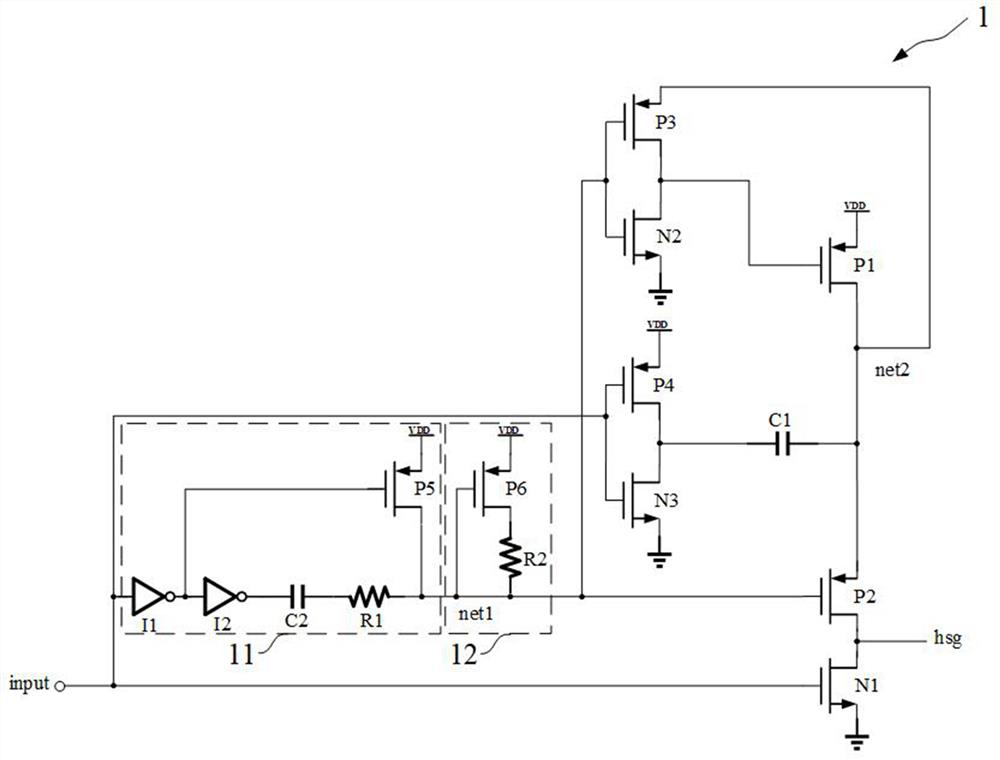

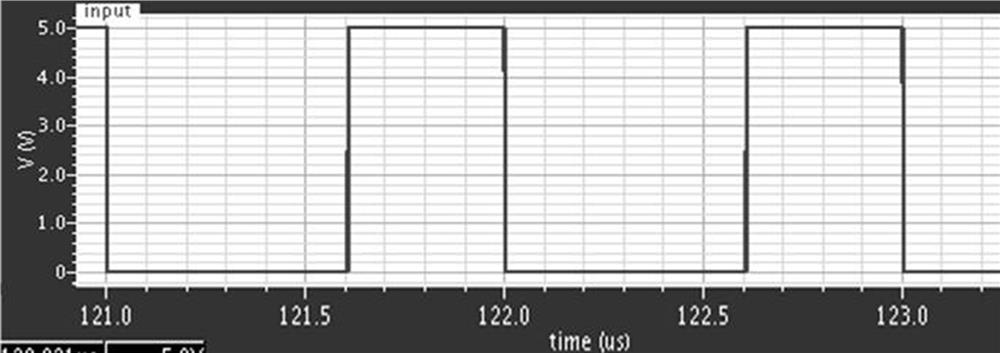

Light adjusting and color adjusting circuit of LED lamp

PendingCN109526104AAchieve dimmingImplement built-inElectrical apparatusElectroluminescent light sourcesPower flowLED lamp

The invention discloses a light adjusting and color adjusting circuit of an LED lamp, and relates to the technical field of LED lamps, wherein the circuit comprises an LED cold light string and an LEDwarm light string connected in parallel with the LED cold light string. The number of LED lamp beads contained in the LED cold light string is N1, and the number of LED lamp beads contained the LED warm light string is N2, wherein N1 and N2 satisfy the relation ofN1*V1>N2*V2, V1 is the turn-on voltage of the LED lamp beads, V2 is the normal working voltage of the LED lamp beads. The initial current when the LED cold light string is not dimmed is I1, and the initial current when the LED warm light string is not dimmed is I2 , and the I1 and I2 satisfy the relation of I1>4*I2. The light adjusting and color adjusting circuit includes a resistor R, and the resistor R is connected in series with the LED warm light string. Two LED light strings of different color temperature, including the LEDcold light string and LED warm light string, are designed, two light strings can be driven with a single driving module to realize dimming, thereby realizing built-in mode when the internal space of MR16 / GU10 is limited and achieving color temperature dimming.

Owner:GUANGDONG NRE TECH

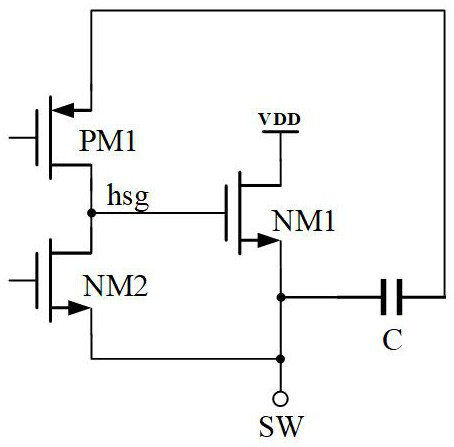

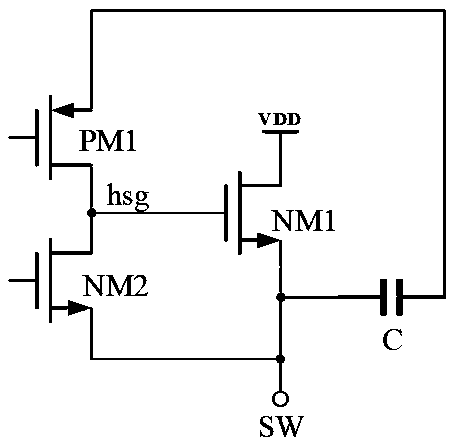

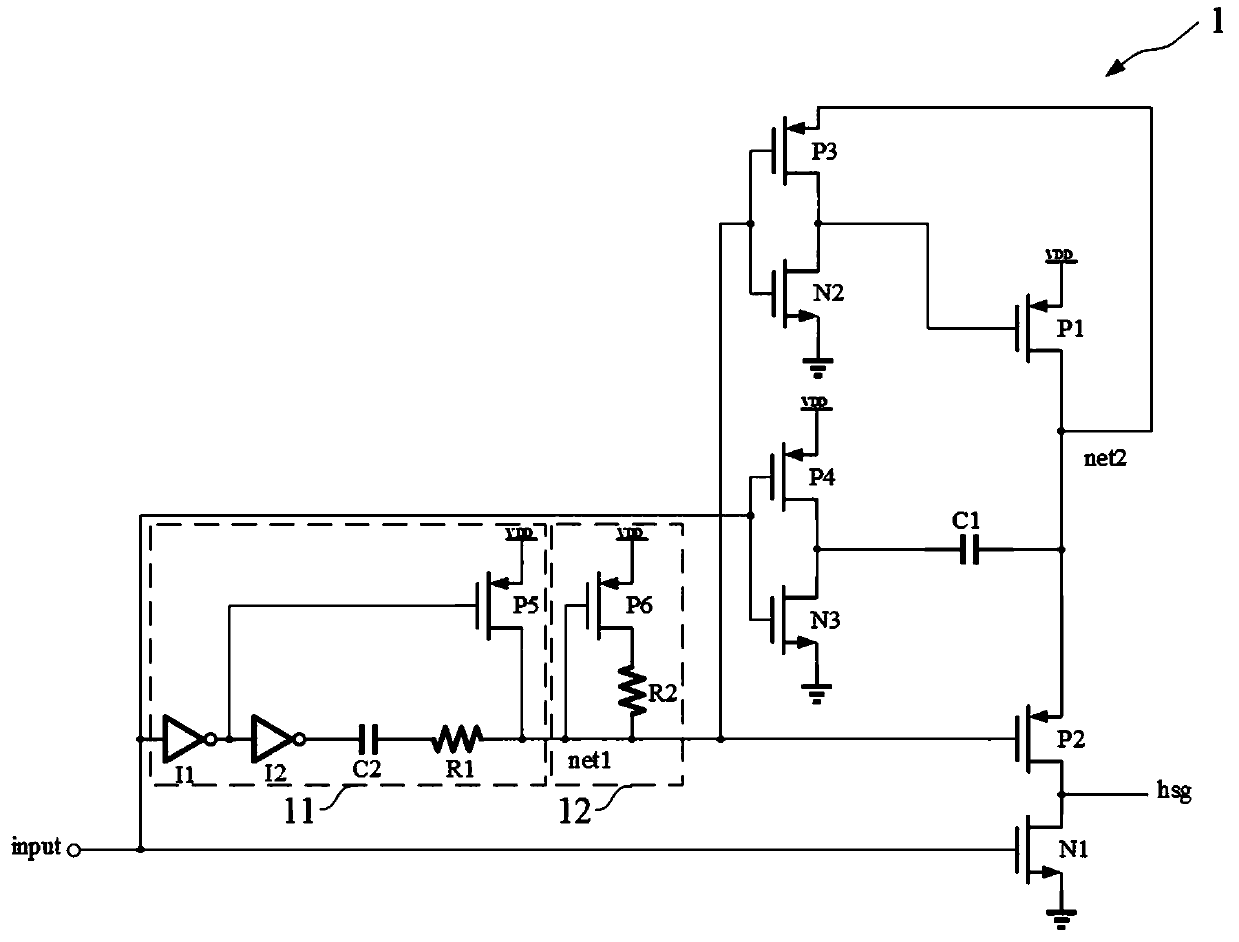

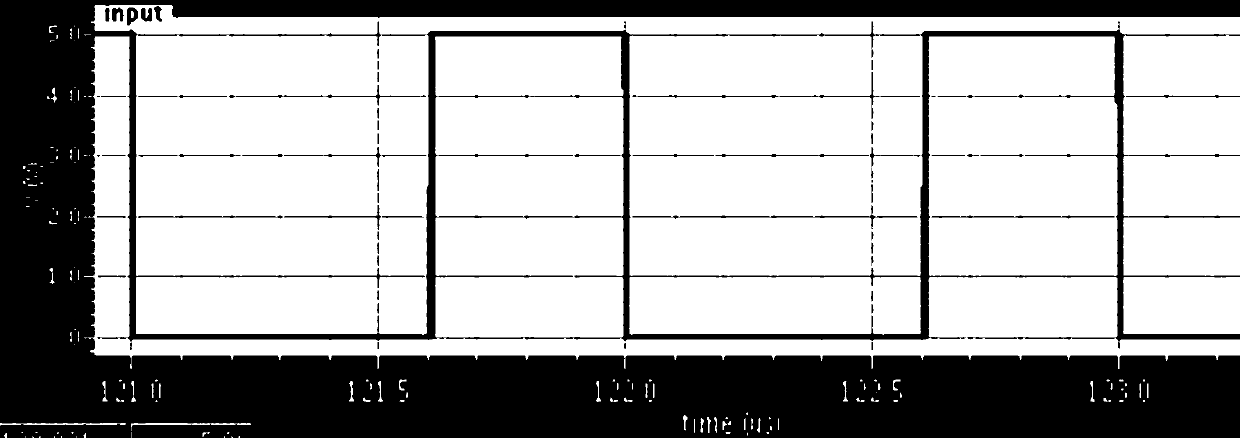

Switch driving circuit of dcdc converter

ActiveCN111600483BReduce capacitanceReduce areaDc-dc conversionElectric variable regulationDriver circuitCapacitance

The invention provides a switch drive circuit of a DCDC converter, comprising a control signal generation module for generating a control signal which is logically consistent with an input signal; wherein the first PMOS tube, the second PMOS tube and the first NMOS tube are connected in series between a power supply and the ground, grid electrodes of the first NMOS tube and the second PMOS tube are respectively connected with an input signal and a control signal, and drain electrodes of the first NMOS tube and the second PMOS tube output driving control signals; the third PMOS transistor and the second NMOS transistor are connected in series between the drain electrode of the first PMOS transistor and the ground, the grid electrodes of the third PMOS transistor and the second NMOS transistor are connected with a control signal, and the drain electrodes of the third PMOS transistor and the second NMOS transistor are connected with the grid electrode of the first PMOS transistor; the fourth PMOS transistor and the third NMOS transistor are connected in series between a power supply and the ground, the grid electrodes of the fourth PMOS transistor and the third NMOS transistor are connected with an input signal, and the drain electrodes of the fourth PMOS transistor and the third NMOS transistor are connected with the drain electrode of the first PMOS transistor through the firstcapacitor. The bootstrap capacitor and the drive circuit are combined, the capacitance value and the area of the bootstrap capacitor can be reduced to one thousandth to one thousandth of the traditional numerical value, the built-in bootstrap capacitor is realized, and the application scheme is simplified.

Owner:SHANGHAI NATLINEAR ELECTRONICS CO LTD

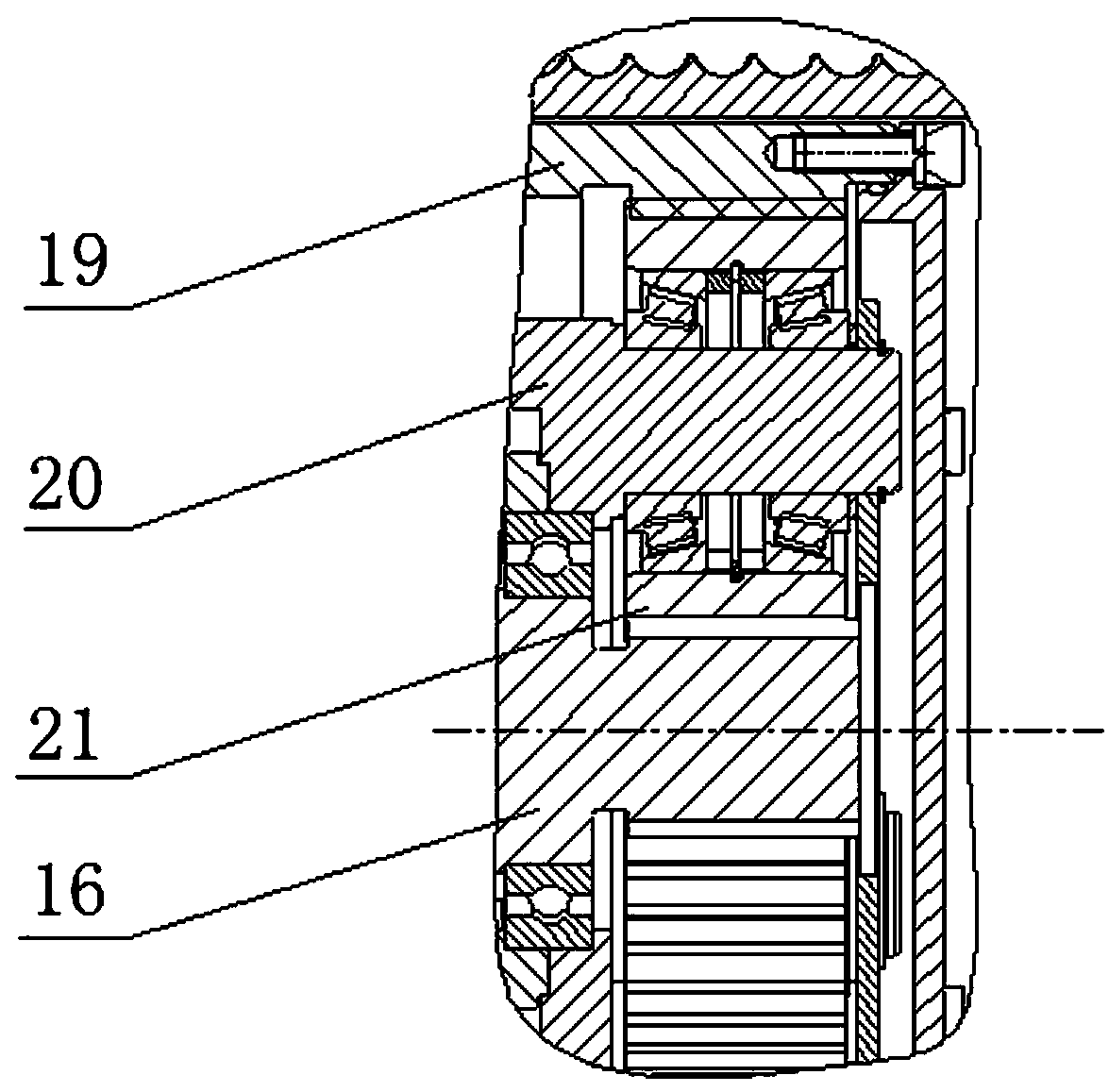

Highly integrated electromechanical actuator

ActiveCN103545977BAchieve direct connectionGuaranteed accuracyMechanical energy handlingLinear variable differential transformerAnti jamming

The invention provides a highly integrated electromechanical actuator comprising a direct drive motor, a ball screw and an LVDT (linear variable differential transformer) which are arranged in a main frame. The direct drive motor comprises a motor stator, a motor rotor and a rotary shaft which are connected sequentially, and the motor rotor and the rotary shaft are produced integrally. The ball screw comprises a round nut and a screw shaft, and the screw shaft is connected to the rotary shaft through the round nut. The LVDT comprises an LVDT fixing sleeve, an LVDT iron core, an LVDT shell and an LVDT extending rod. The LVDT shell is arranged in the screw shaft and is connected to a left end cover through the LVDT fixing sleeve, the LVDT extending rod is arranged in the LVDT shell and is connected to the screw shaft, and the LVDT iron core is arranged in the LVDT shell and is connected with the LVDT extending rod. The highly integrated electromechanical actuator has the advantages of simple structure, convenience for mounting, small size, light weight, strong bearing capacity, high moving accuracy and transmission efficiency, good anti-jamming performance and low cost.

Owner:SHANGHAI JIAOTONG UNIV

Switch drive circuit of DCDC converter

ActiveCN111600483AReduce capacitanceReduce areaDc-dc conversionElectric variable regulationDriver circuitCapacitance

The invention provides a switch drive circuit of a DCDC converter, comprising a control signal generation module for generating a control signal which is logically consistent with an input signal; wherein the first PMOS tube, the second PMOS tube and the first NMOS tube are connected in series between a power supply and the ground, grid electrodes of the first NMOS tube and the second PMOS tube are respectively connected with an input signal and a control signal, and drain electrodes of the first NMOS tube and the second PMOS tube output driving control signals; the third PMOS transistor and the second NMOS transistor are connected in series between the drain electrode of the first PMOS transistor and the ground, the grid electrodes of the third PMOS transistor and the second NMOS transistor are connected with a control signal, and the drain electrodes of the third PMOS transistor and the second NMOS transistor are connected with the grid electrode of the first PMOS transistor; the fourth PMOS transistor and the third NMOS transistor are connected in series between a power supply and the ground, the grid electrodes of the fourth PMOS transistor and the third NMOS transistor are connected with an input signal, and the drain electrodes of the fourth PMOS transistor and the third NMOS transistor are connected with the drain electrode of the first PMOS transistor through the firstcapacitor. The bootstrap capacitor and the drive circuit are combined, the capacitance value and the area of the bootstrap capacitor can be reduced to one thousandth to one thousandth of the traditional numerical value, the built-in bootstrap capacitor is realized, and the application scheme is simplified.

Owner:SHANGHAI NATLINEAR ELECTRONICS CO LTD

Standardized multifunctional self-locking and thread-locking liquid dispensing pump with built-in spring

ActiveCN105947390BRealize standardized productionEasy to produceClosuresLiquid spraying apparatusPump chamberEngineering

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com