Built-in hydraulic winch

A hydraulic winch and built-in technology, which is applied in the field of hydraulic winches, can solve the problems of inconvenient operation and use of truck-mounted cranes, increase the difficulty of structural layout space, and long axial structure of cycloidal motors, so as to save internal space and improve manufacturing Manufacturability, good effect of processing and manufacturing manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and embodiments.

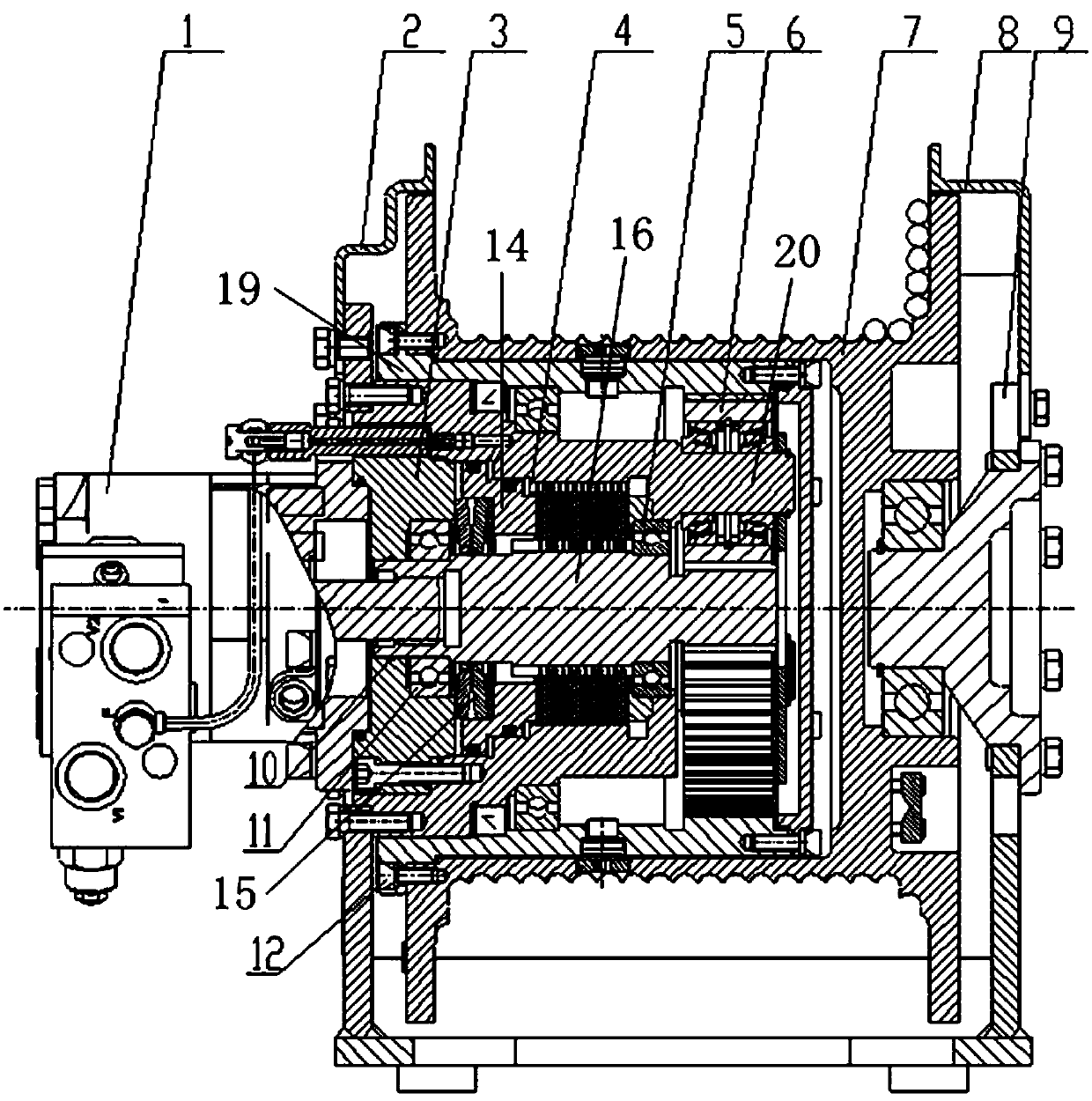

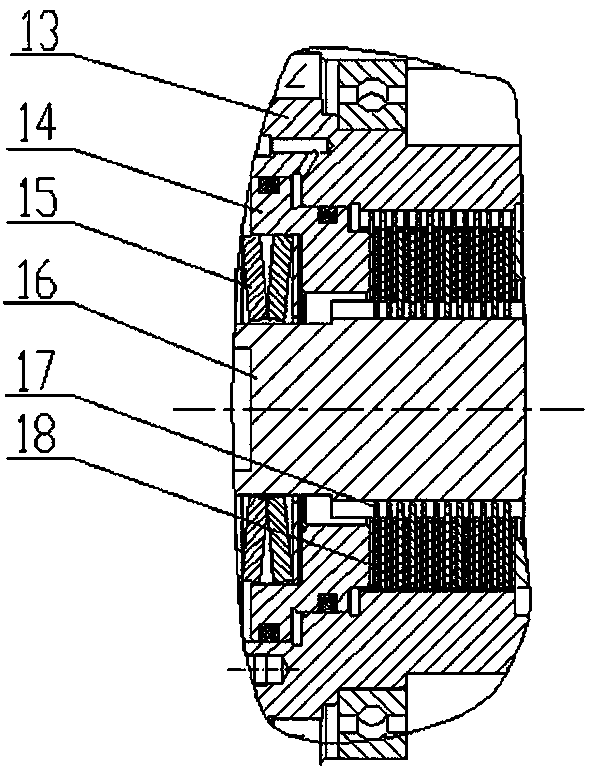

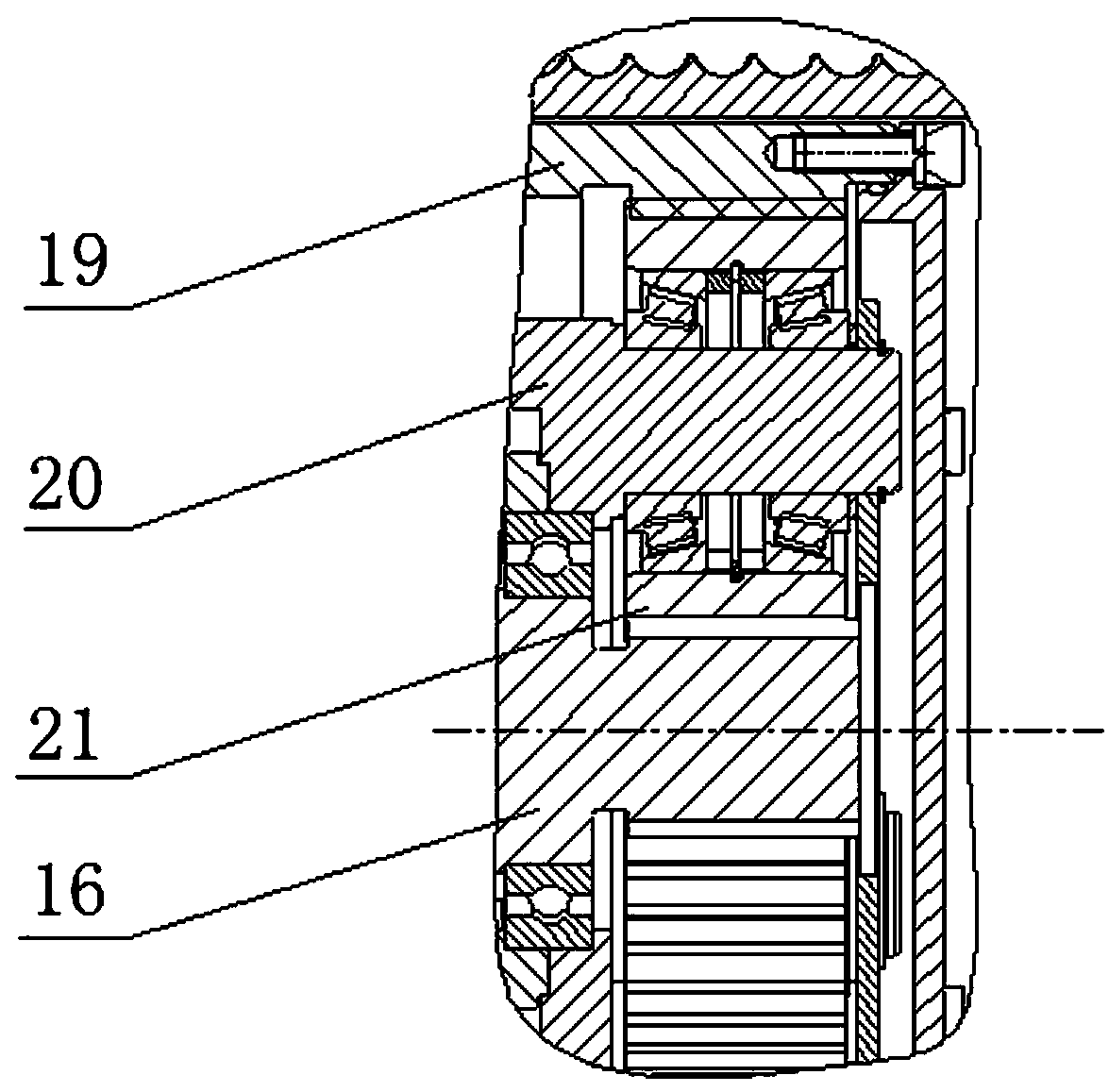

[0022] Such as Figure 1 to Figure 3 As shown, a built-in hydraulic winch includes a hydraulic motor 1, a brake 4, a planetary reduction mechanism 6, a reel 7 and a bracket 9, the hydraulic motor 1 is fixedly connected to the motor connection plate 3, and the motor connection plate 3 is fixed to the brake In the inner cavity of the brake core 13 of 4, the inner hole of the motor connection plate 3 is set on the axle of the sun gear 16 through the bearing II11, and the bearing II11 is used to align the axle of the sun gear 16 close to the hydraulic motor 1 and the hydraulic motor 1 The output shaft of the brake core 13 is supported by the output shaft, and the outer circumference of the brake core 13 is fixedly connected with the bracket 9 by bolts. The bearing I5 is set between the brake core 13 and the axle of the sun gear 16 to support the side of the sun ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com