Weaving machine and preparation method for conductive fabric

A loom and fiber weaving technology, which is applied in the field of loom and conductive fabric preparation, can solve the problems of long reaction time, complicated preparation process, and large consumption of reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] The present invention also provides a preparation method of conductive fabric, comprising:

[0086] After the fibers to be woven are adsorbed by aniline gas, they are polymerized under plasma conditions, and the obtained conductive fibers are woven as weft yarns and warp yarns to obtain conductive fabrics.

[0087] In the present invention, the fibers to be woven first absorb aniline through an aniline gas generator, and then polymerize aniline in situ in a plasma polymerization reactor to form a polyaniline conductive coating on the surface of the fibers to be woven to obtain conductive fibers; The fibers are used as weft yarns, which are woven with warp yarns to obtain conductive fabrics.

[0088] In the present invention, the fiber to be woven is used as the raw material, after being adsorbed by aniline gas in sequence, the aniline is subjected to in-situ polymerization reaction under plasma conditions, and a conductive coating is formed on the surface of the fiber t...

Embodiment 1

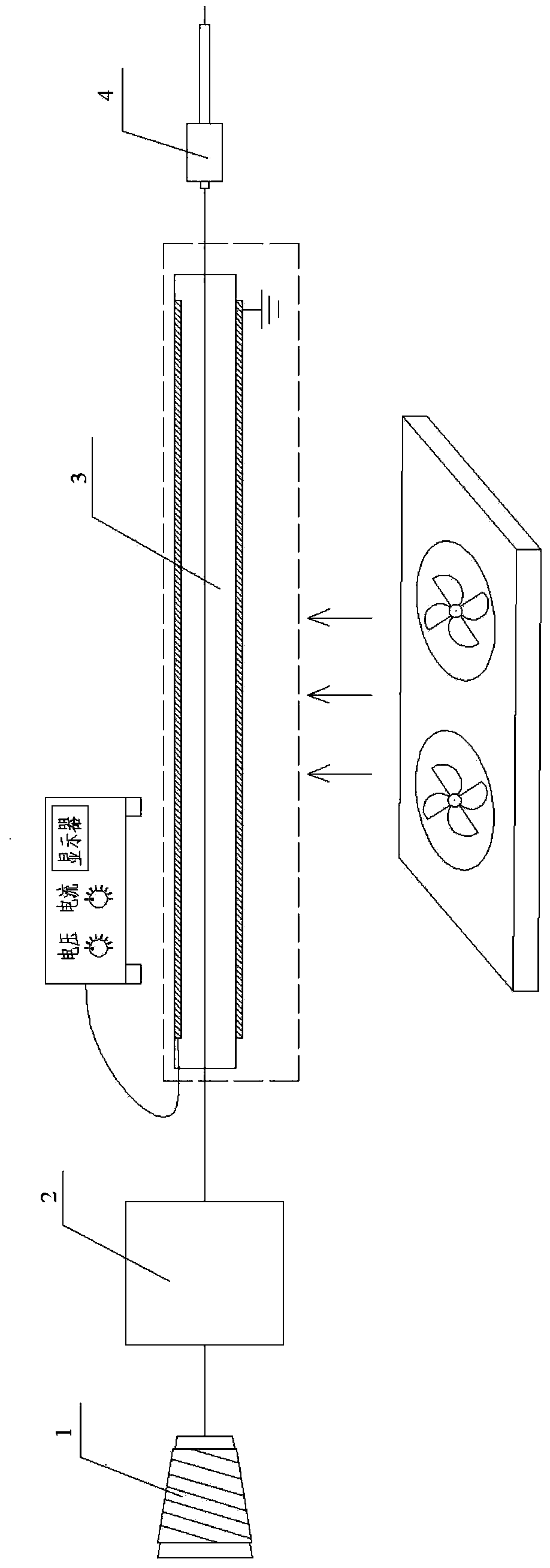

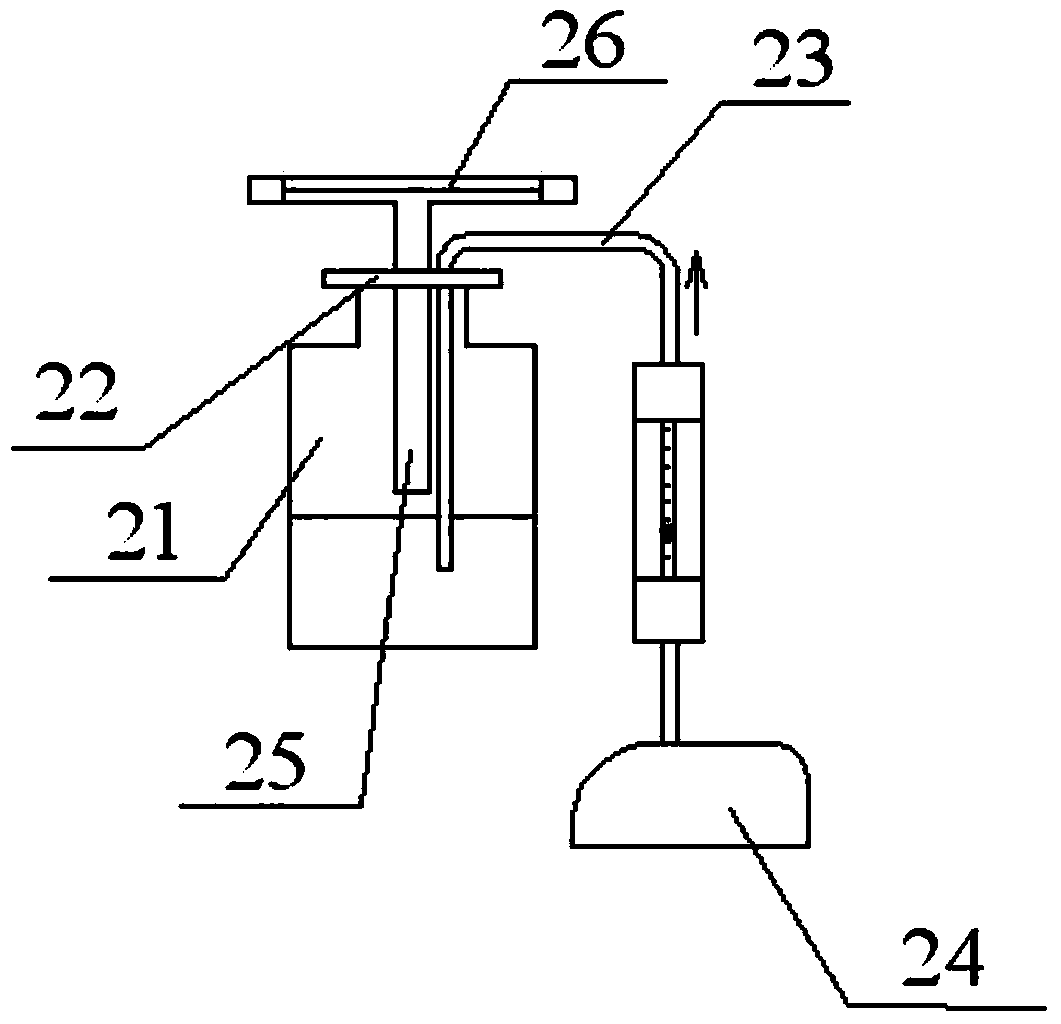

[0098] see Figure 5 , Figure 5 The partial structure diagram of the loom provided for the embodiment 1 of the present invention, the loom comprises: weft feeder 4, aniline gas generator 1, hydrogen chloride gas generator 2, plasma polymerization reactor 3 and weft insertion device (not shown in the figure Shown in), wherein, the aniline gas generator comprises: aniline solution storage bottle, the sealing cover that is arranged on the aniline solution storage bottle, the inlet pipe that is positioned at the aniline solution liquid level, the inlet pipe is connected with the inlet pump through flow meter, is positioned at The air outlet pipe above the liquid level of the aniline solution, and the aniline gas storage pipe connected to the other end of the air outlet pipe;

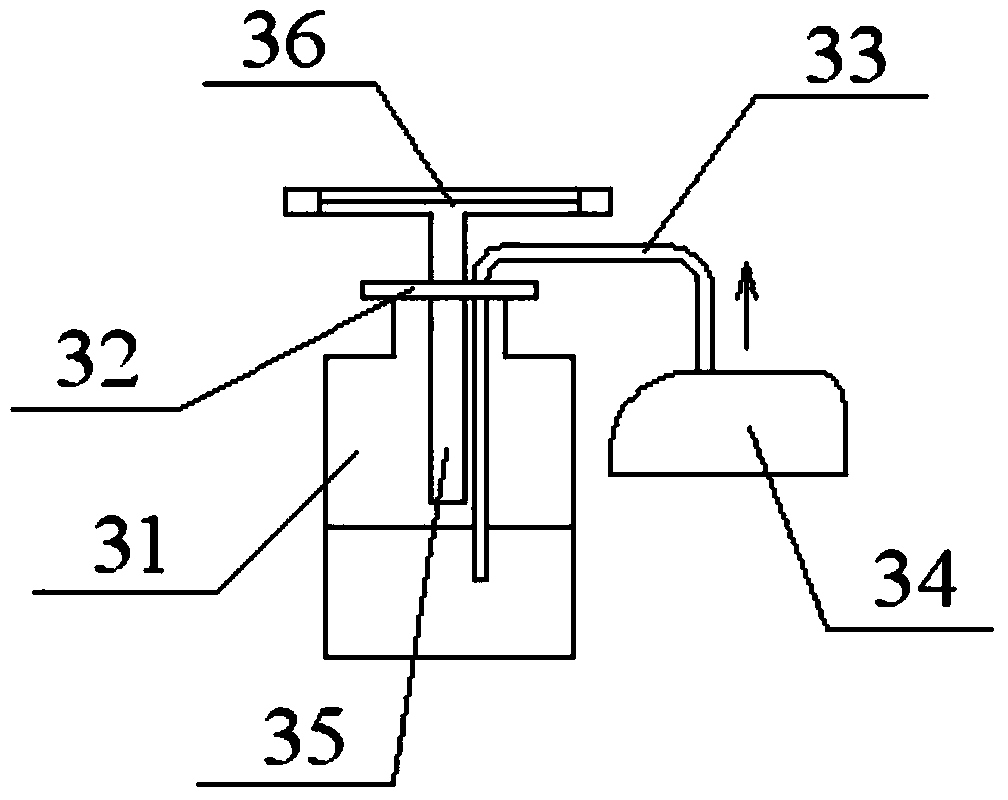

[0099] The hydrogen chloride gas generator includes: a hydrochloric acid solution storage bottle, a sealing cover arranged on the hydrochloric acid solution storage bottle, an air inlet pipe located below ...

Embodiment 2~4

[0102] Using polyester yarns with a specification of 150D / 299F, an average value of specific resistance of 2500MΩ·cm, and a length of 2m as raw materials, polyaniline modification was carried out in the preparation device provided in Example 1. During the modification process, in the aniline gas generator, Nitrogen is used as the intake air, and the blowing volume of nitrogen gas is 30L / h, 60L / h and 90L / h respectively; in the hydrogen chloride gas generator, air is used as the intake air, and the blowing volume of air is 30L / h, 60L / h respectively. h and 90L / h; in the plasma polymerization reactor, the output voltage of the plasma generator power supply is 32v, and the polymerization time is 3s, that is, the residence time of the yarn in the plasma polymerization reactor is 3s, and the conductive fiber is obtained.

[0103] Carry out scanning electron microscope observation to the conductive fiber prepared by embodiment 4 and the original polyester fiber, the results can be foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com