Point type optical fiber smoke-sensing fire detector with built-in spectroscopic optical fiber as signal indication

A fire detector and signal indication technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as hidden safety hazards, increase labor costs, increase production costs, etc., and achieve the effect of reducing length, saving labor costs, and saving light sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

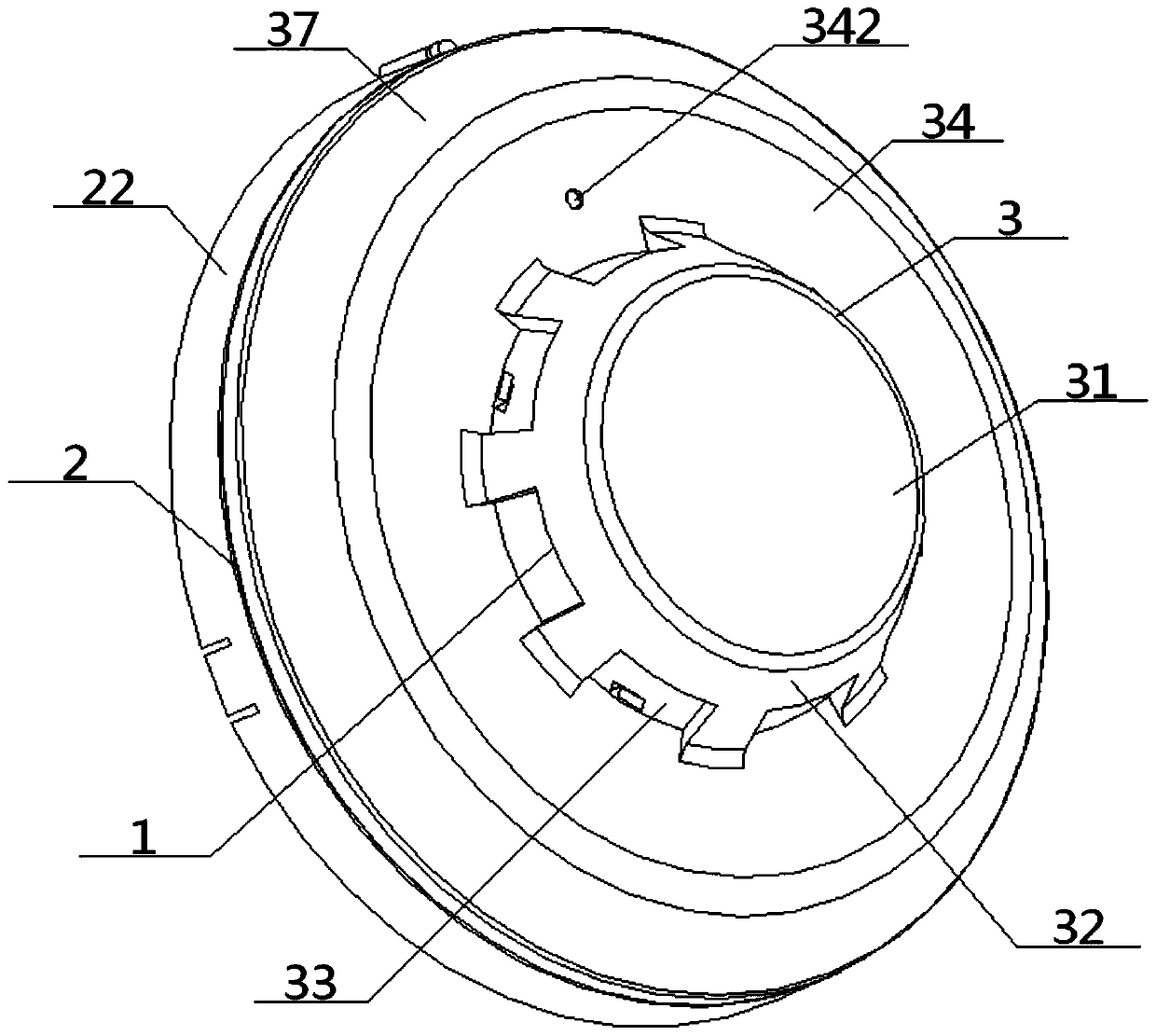

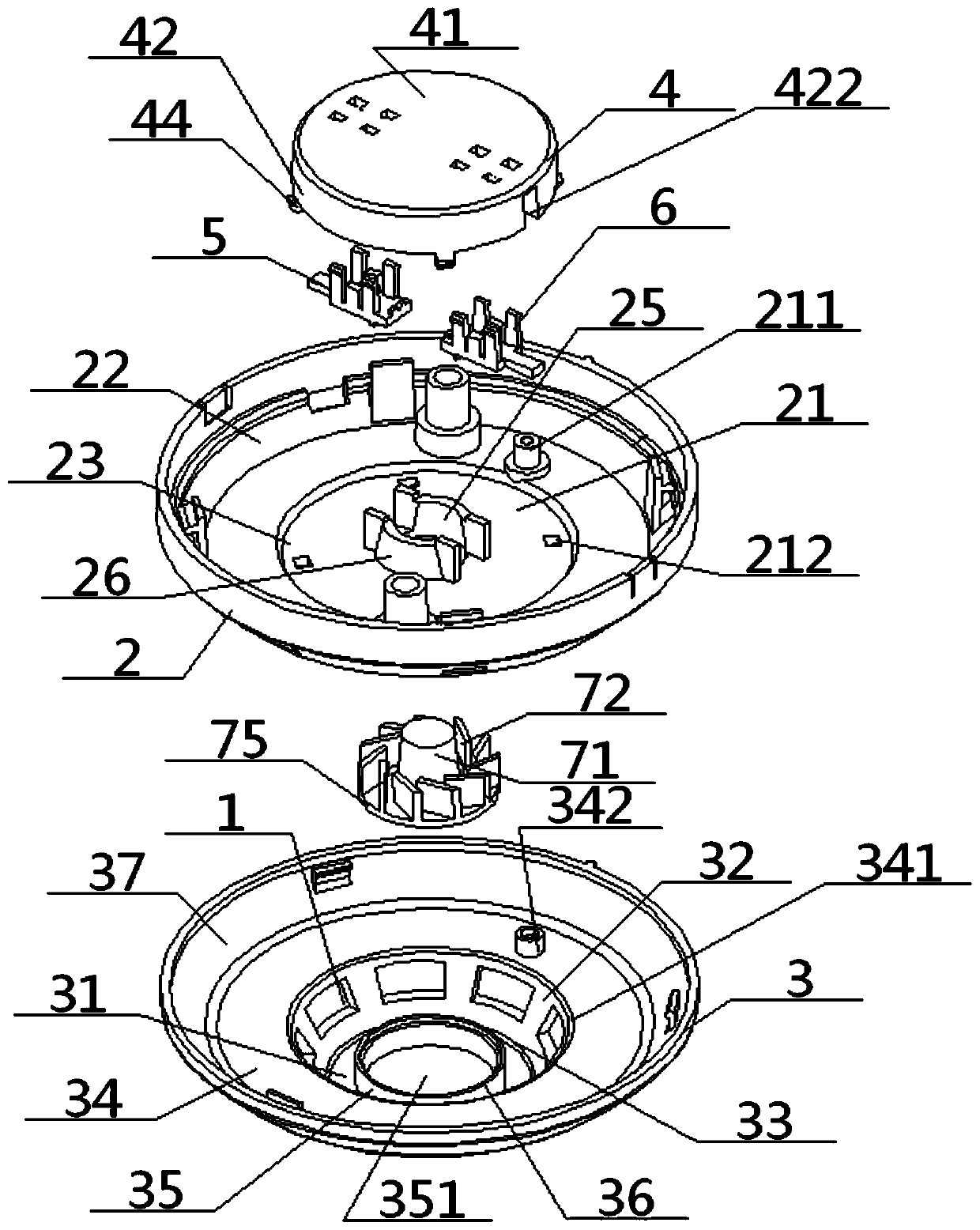

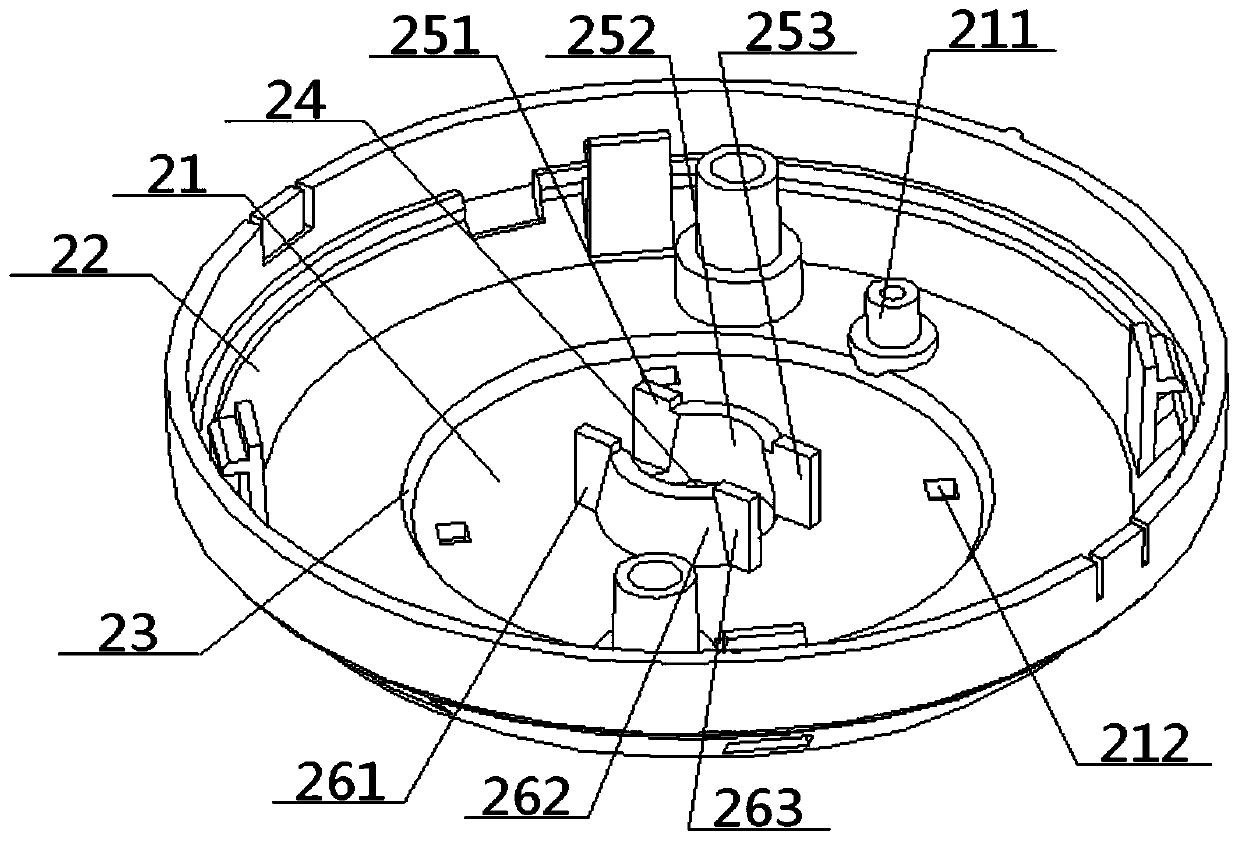

[0057] see Figure 1 to Figure 13 , a point-type optical fiber smoke fire detector with a built-in spectroscopic optical fiber for signal indication, including a base shell 2 and a bottom shell 3 both of which are hollow structures, and the base shell 2 includes a base plate 21 and is connected to its surroundings The base side wall 22, the base side wall 22, the base plate 21 surround a base shell cavity 23, the bottom shell 3 includes a bottom shell plate 31 and a bottom side wall 32, one end of the bottom side wall 32 is connected to The bottom surface of the base plate 21 is connected, and the other end of the bottom side coaming plate 32 is connected with the surroundings of the bottom shell plate 31. The bottom side coaming plate 32 and the bottom shell plate 31 form a bottom shell cavity 33, and the bottom side coaming plate 32 is provided with a smoke inlet 1 communicating with the bottom shell cavity 33; the point-type optical fiber smoke fire detector also includes a...

Embodiment 2

[0059] Basic content is the same as embodiment 1, the difference is:

[0060] The bottom shell 3 also includes a bottom shell ring plate 34, and the middle part of the bottom shell ring plate 34 is provided with a bottom shell ring hole 341 in contact with the bottom shell cavity 33, and the bottom surface of the bottom shell ring plate 34 is close to the bottom shell ring. The hole 341 is connected to the top of the bottom side panel 32, the top surface of the bottom shell ring plate 34 is connected to the bottom surface of the base plate 21, and the bottom shell ring plate 34 is provided with a signal hole corresponding to the base shell signal hole 211. The signal hole 342 of the bottom case.

Embodiment 3

[0062] Basic content is the same as embodiment 1, the difference is:

[0063] The receiving optical fiber clamping part 6 includes a receiving fixed seat 62 and a receiving movable seat 63, the bottom of the receiving fixed seat 62 is connected with the box top plate 41, and a receiving half groove 620 is opened in the top of the receiving fixed seat 62. The receiving movable seat 63 includes a receiving bottom plate 64, a receiving supporting plate 65, and receiving inner splints 66 and receiving outer splints 67 facing to each other. The bottom ends of 65 are connected, and the top of receiving supporting plate 65 is provided with supporting plate half groove 651, and the tops of receiving inner clamping plate 66 and receiving outer clamping plate 67 extend upwards, receiving inner clamping plate 66 and receiving outer clamping plate 67 to form a The clamping column cavity 68 coaxial with the supporting plate half-groove 651 , the clamping column cavity 68 , the supporting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com