Hydrogenated reactive emulsifier with excellent stability and water resistance, and preparation method and application thereof

A reactive emulsifier and emulsifier technology, applied in the field of surfactants, can solve problems such as application limitations, difficult biocompatibility and environmental protection, and product performance that does not meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

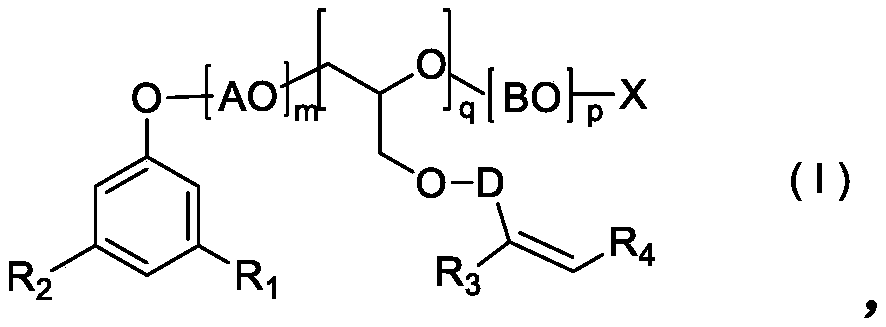

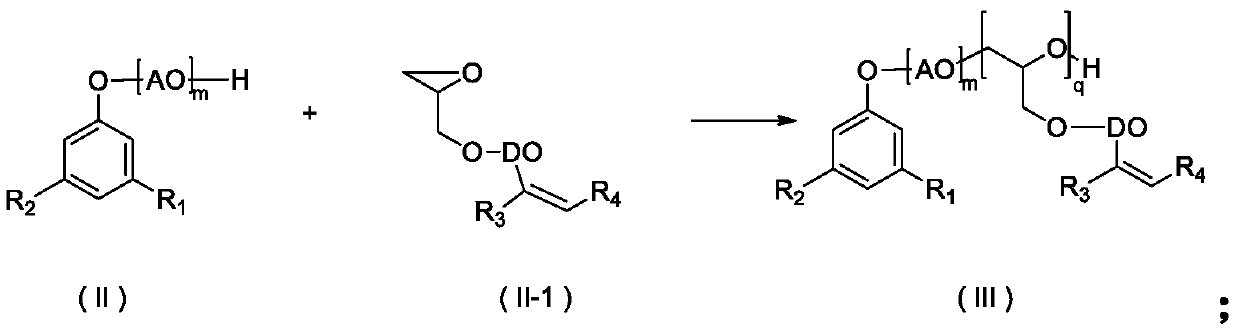

Method used

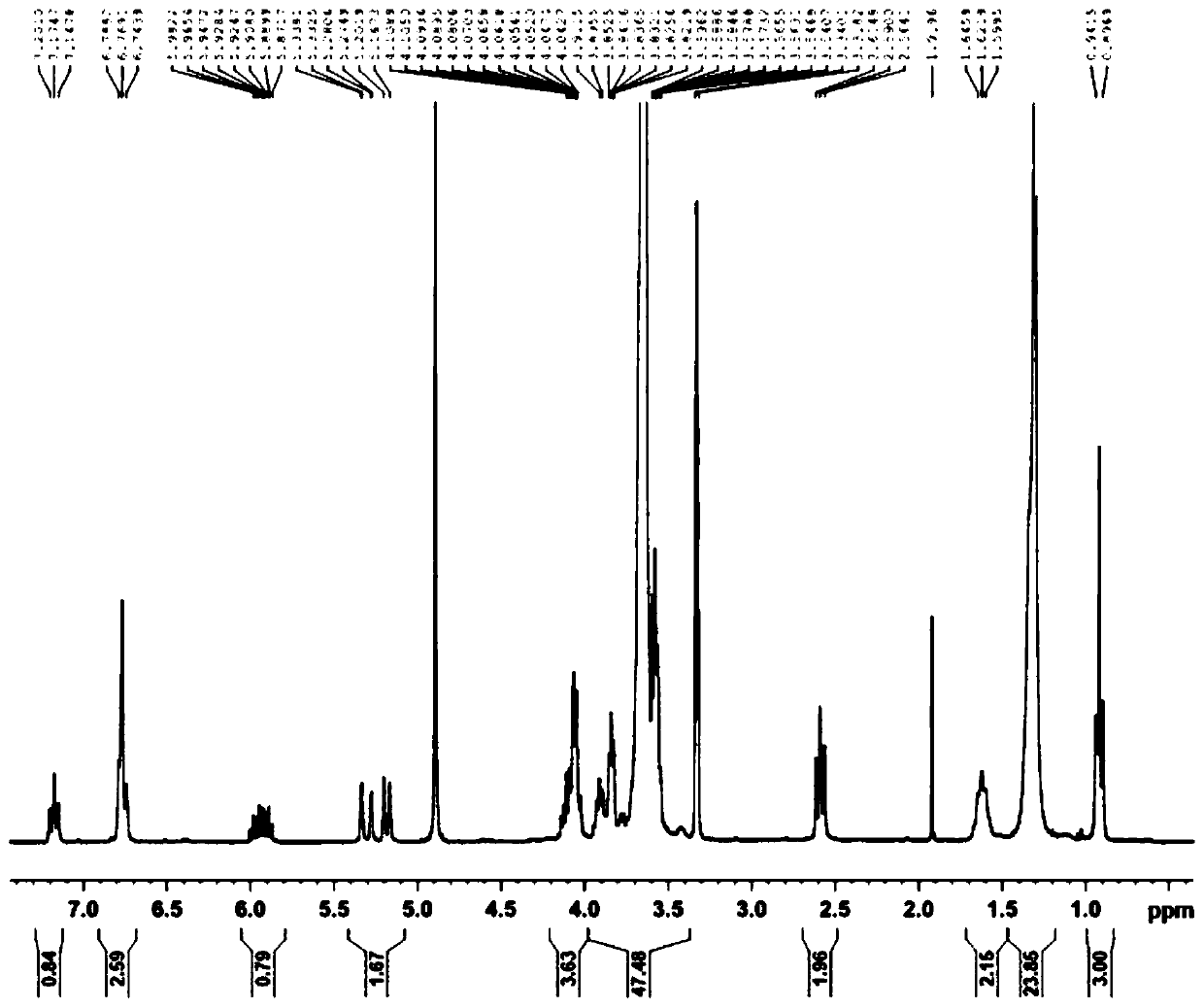

Image

Examples

Embodiment 1

[0084]The molar ratio of hydrogenated cardanol to allyl glycidyl ether is 1 / 1.05, weigh 200g of hydrogenated cardanol (actually measured hydroxyl value 184.24mgKOH / g) with a moisture content (<1000ppm) into the reactor, and add 0.92gNaH , under the protection of nitrogen, stir and heat up to 90°C. Slowly add a total of 86.65 g of allyl glycidyl ether to the reaction kettle dropwise, the dropwise addition is completed within 1 hour, continue to stir for 8 hours, lower the temperature, and take a sample of 1-1#.

Embodiment 2

[0086] With reference to the method of Example 1, the molar ratio of hydrogenated cardanol and allyl glycidyl ether is 1 / 1.05. Weigh 255g of hydrogenated cardanol into the reaction kettle, add 1.15g of NaH, stir and raise the temperature to 90°C under the protection of nitrogen. Slowly add a total of 108.1 g of allyl glycidyl ether to the reaction kettle dropwise, and the dropwise addition is completed within 1 hour, continue to stir for 4 hours, and take a sample of 1-2#-1; continue to stir and react until 8 hours, and take a sample of 1 -2#-2 samples.

Embodiment 3

[0088] With reference to the method of Example 1, the molar ratio of hydrogenated cardanol and allyl glycidyl ether is 1 / 2.0. Weigh 300g of hydrogenated cardanol into the reaction kettle, add 1.35g of NaH, stir and raise the temperature to 80°C under the protection of nitrogen. Slowly add 130g of allyl glycidyl ether dropwise to the reaction kettle, the dropwise addition is completed within 1 hour, continue to stir for 4 hours, lower the temperature, take a sample of 1-3#-2, continue to stir for 8 hours, and take a sample of 1-3#-2 3#-1 sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com