A reactive emulsifier, its preparation method and application

A reactive emulsifier and reaction technology, applied in the direction of coating, etc., can solve the problems of reduced effective double bond content, reduced product reactivity, high reaction temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

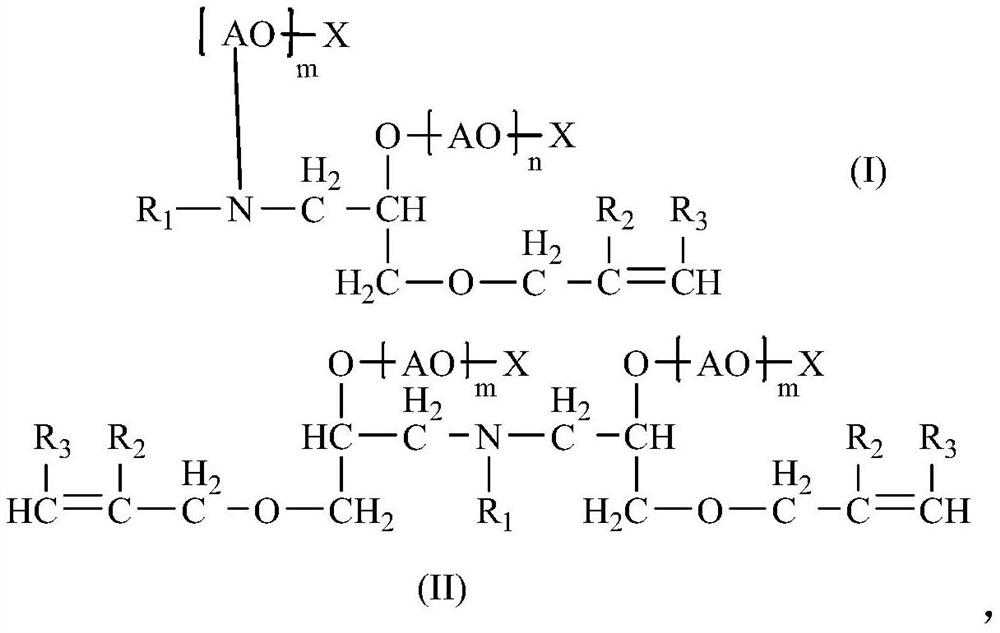

AI Technical Summary

Problems solved by technology

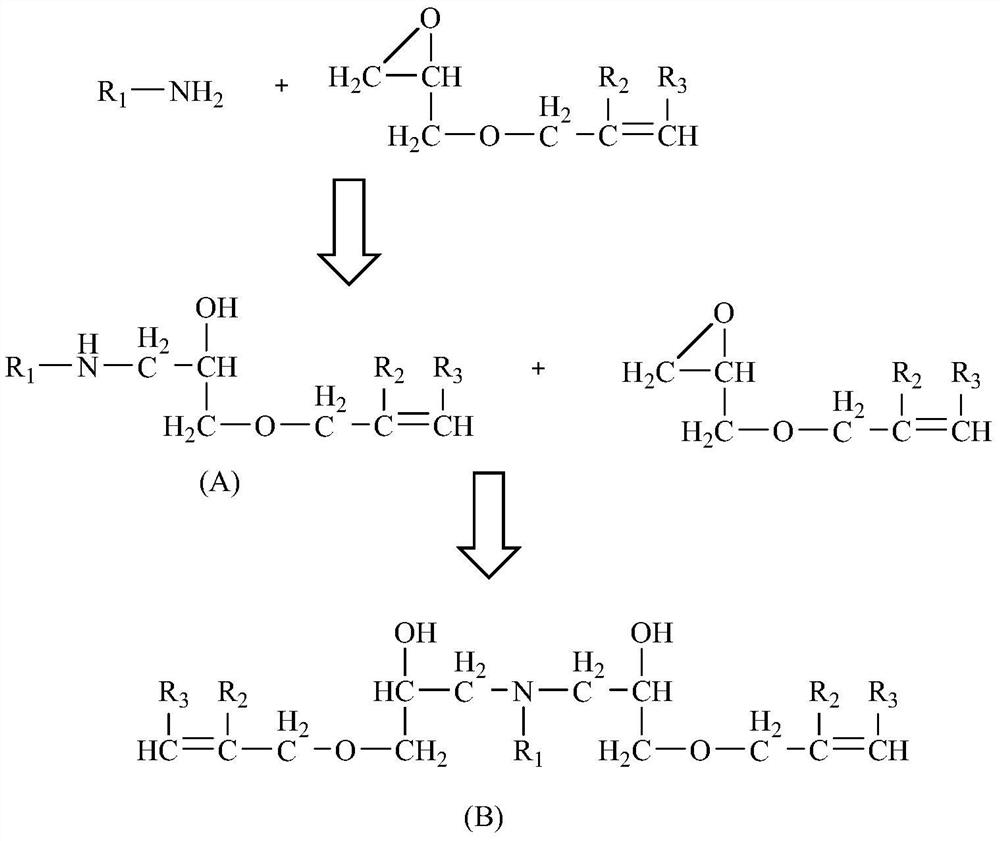

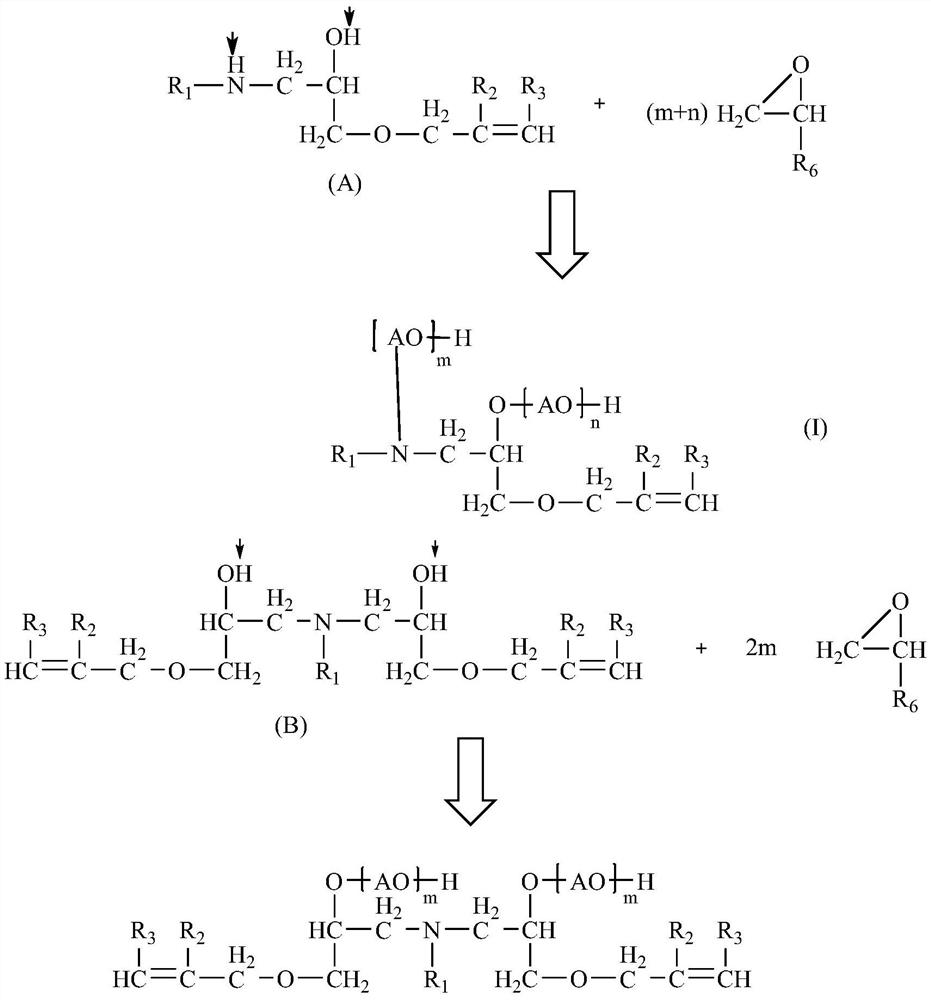

Method used

Image

Examples

Embodiment 1

[0048] Using coconut oil primary amine (C12 / 14 primary amine, C) react with allyl glycidyl ether, the reaction pressure is normal pressure, the molar ratio of coconut oil primary amine and allyl glycidyl ether is 1 / 1.05, and the molar weight of coconut oil primary amine can be according to The amine value index of C product (272~285mgKOH / g) or the actual measured amine value calculation.

[0049] Weigh 200g of water up to standard ( C Coconut oil primary amine (measured total amine value 275mgKOH / g) is put into the reaction kettle, and under the protection of nitrogen, stir and heat up to 30°C. Slowly add a total of 117.56 g of allyl glycidyl ether to the reaction kettle dropwise, the dropwise addition is completed within 1 hour, continue to stir for 7 hours, lower the temperature, and take a sample of 1-1#.

Embodiment 2

[0051] With reference to the method of Example 1, the molar ratio of coconut oil primary amine and allyl glycidyl ether is 1 / 1.05. Weigh the coconut oil primary amine into the reaction kettle, stir and raise the temperature to 90°C under the protection of nitrogen. Slowly add allyl glycidyl ether dropwise to the reaction kettle, the dropwise addition is completed within 1 hour, continue to stir for 3 hours, lower the temperature, and take samples as 1-2# samples.

[0052] According to the feeding ratio of coconut oil primary amine and allyl glycidyl ether in embodiment 1 and embodiment 2, gained 1-1# sample and 1-2# sample are mainly made up of the compound of following formula (A-1) structure,

[0053]

[0054] where R 1 It is mainly an alkyl group with 8 to 16 carbon atoms, because the fatty primary amine raw material comes from natural coconut oil.

Embodiment 3

[0056] With reference to the method of Example 1, the molar ratio of coconut oil primary amine and allyl glycidyl ether is 1 / 2.0. Weigh the coconut oil primary amine into the reaction kettle, stir and raise the temperature to 30°C under the protection of nitrogen. Slowly add allyl glycidyl ether dropwise to the reaction kettle, the dropwise addition is completed within 2 hours, continue to stir for 6 hours, lower the temperature, and take samples as 1-3# samples.

[0057] According to the feeding ratio of coconut oil primary amine and allyl glycidyl ether in embodiment 3, gained 1-3# sample mainly is made up of formula (B-1) structure compound,

[0058]

[0059] where R 1 It is mainly an alkyl group with 8 to 16 carbon atoms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com