Reactive emulsifier and preparation method and application thereof

A reactive emulsifier, emulsifier technology, applied in the field of surfactants, can solve problems such as application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

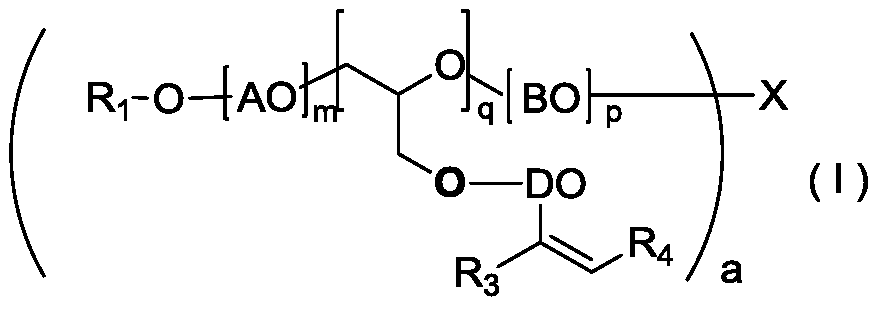

Method used

Image

Examples

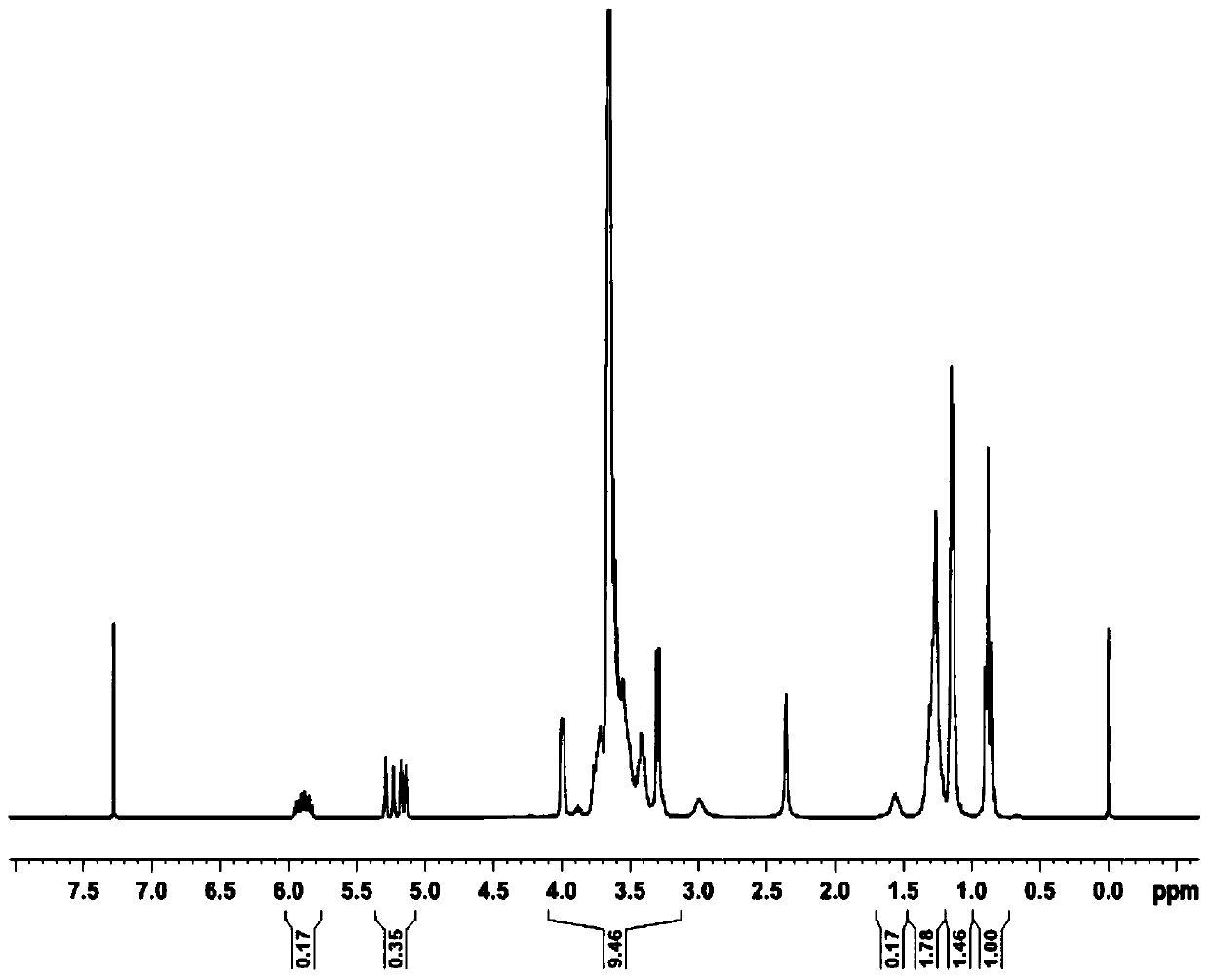

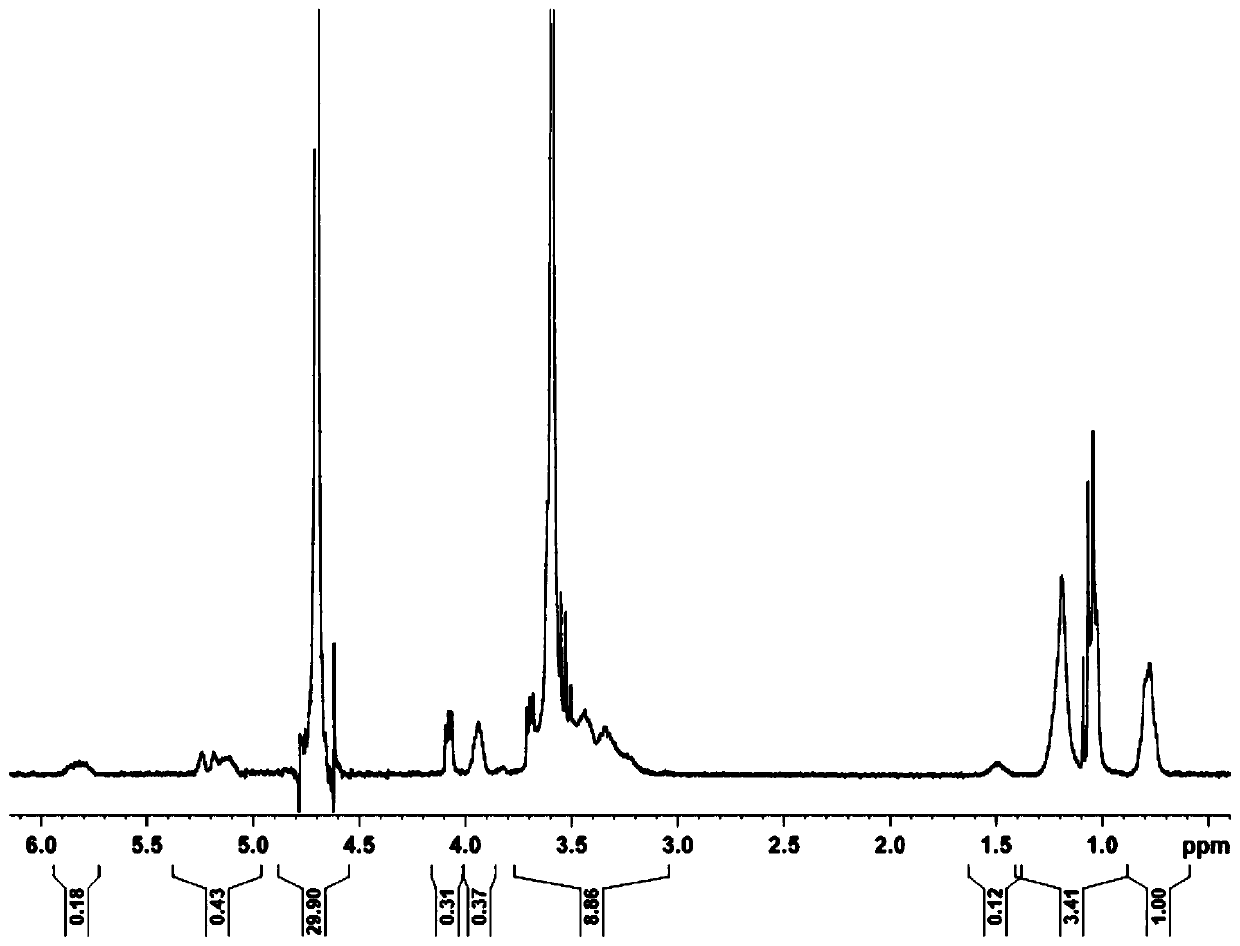

Embodiment 1

[0098] The molar ratio of isomeric carbooctaol (2-EH alcohol) and allyl glycidyl ether is 1 / 1.05, and 200g of 2-EH alcohol (measured hydroxyl value 431.5mgKOH / g) is weighed up to the standard (<1000ppm) ) into the reaction kettle, add 0.9gNaH, under the protection of nitrogen, stir and heat up to 90°C. Slowly add a total of 184.5 g of allyl glycidyl ether to the reaction kettle dropwise, the dropwise addition is completed within 1 hour, continue to stir for 8 hours, cool down to 50-60°C, and take a sample of 1-1#.

Embodiment 2

[0100] Referring to the method of Example 1, the molar ratio of 2-EH alcohol to allyl glycidyl ether is 1 / 1.05. Weigh 250g of 2-EH alcohol into the reaction kettle, add 1.13g of NaH, stir and raise the temperature to 90°C under the protection of nitrogen. Slowly add a total of 230.1 g of allyl glycidyl ether dropwise to the reactor, and the dropwise addition is completed within 1 hour, continue to stir and react for 4 hours, and sample 1-2#-1 sample; continue to stir and react for 8 hours, and sample as 1-2#-2 samples.

Embodiment 3

[0102] Referring to the method of Example 1, the molar ratio of 2-EH alcohol to allyl glycidyl ether is 1 / 2.0. Weigh 300g of 2-EH alcohol into the reaction kettle, add 1.35g of NaH, stir and raise the temperature to 80°C under the protection of nitrogen. Slowly add 526.8g of allyl glycidyl ether dropwise to the reaction kettle, the dropwise addition is completed within 1 hour, continue to stir and react for 4 hours, cool down, take a sample of 1-3#-2, continue to stir for 8 hours, and take a sample of 1-3#-1 sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com