Composite overrunning clutch

An overrunning clutch, overrunning clutch technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve problems such as increasing energy consumption, reducing service life, increasing idle angle and meshing impact, and improving meshing sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

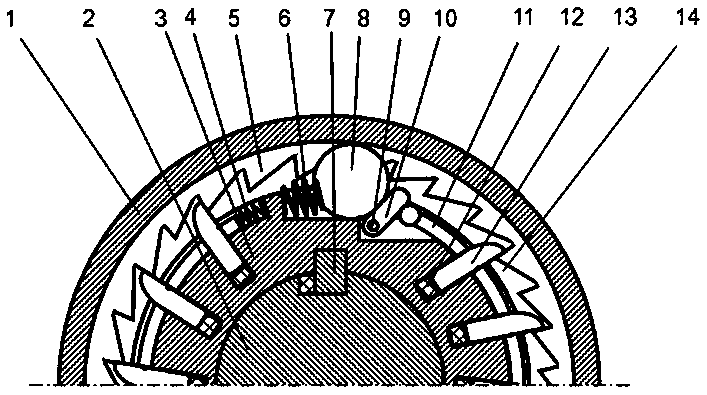

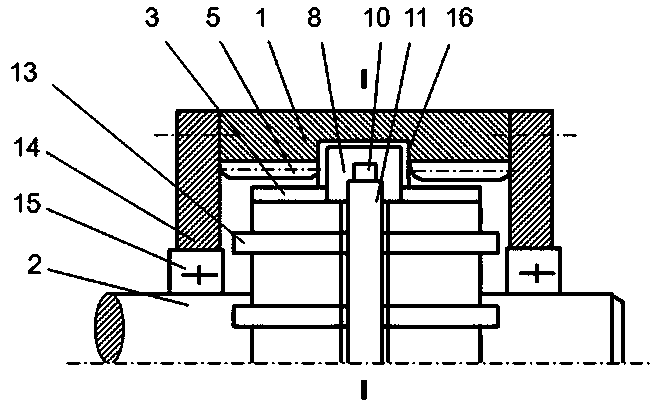

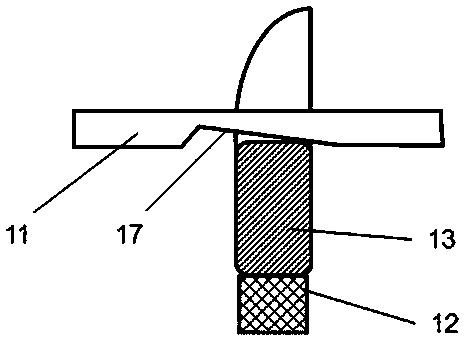

[0013] refer to figure 1 , figure 2 or image 3 , the shaft 2 is fixedly connected to the inner ring 3 through the key 7, and is rotationally connected to the end cover 14 through the bearing 15. The end cover 14 is fixedly connected to the outer ring 1; Ratchet 5; spring 6, roller 8 and its movable platform, lever 10, push ring 11, elastic block 12, pawl 13 are arranged on the inner ring 3, and the pawl 13 can slide or swing radially with the ratchet 5 Engage or disengage, the number of which can be divisible by the number of ratchets 5, evenly distributed in the circumferential direction, the lever 10 is rotationally connected with the inner ring 3 through the pin 9, the push ring 11 is movably connected with the pawl 13 through the wedge surface 17; the roller 8 is kept in contact with the raceway 16 of the outer ring 1 under the pressure of the spring 5, and at the same time, the roller 8, the lever 10 and the pawl 13 are also kept in dynamic contact under the bidirecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com