Thermostatic element, in particular, for a cooling circuit and a method for the production thereof

A technology of constant temperature components and components, applied in the field of manufacturing such components, to achieve the effect of small extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

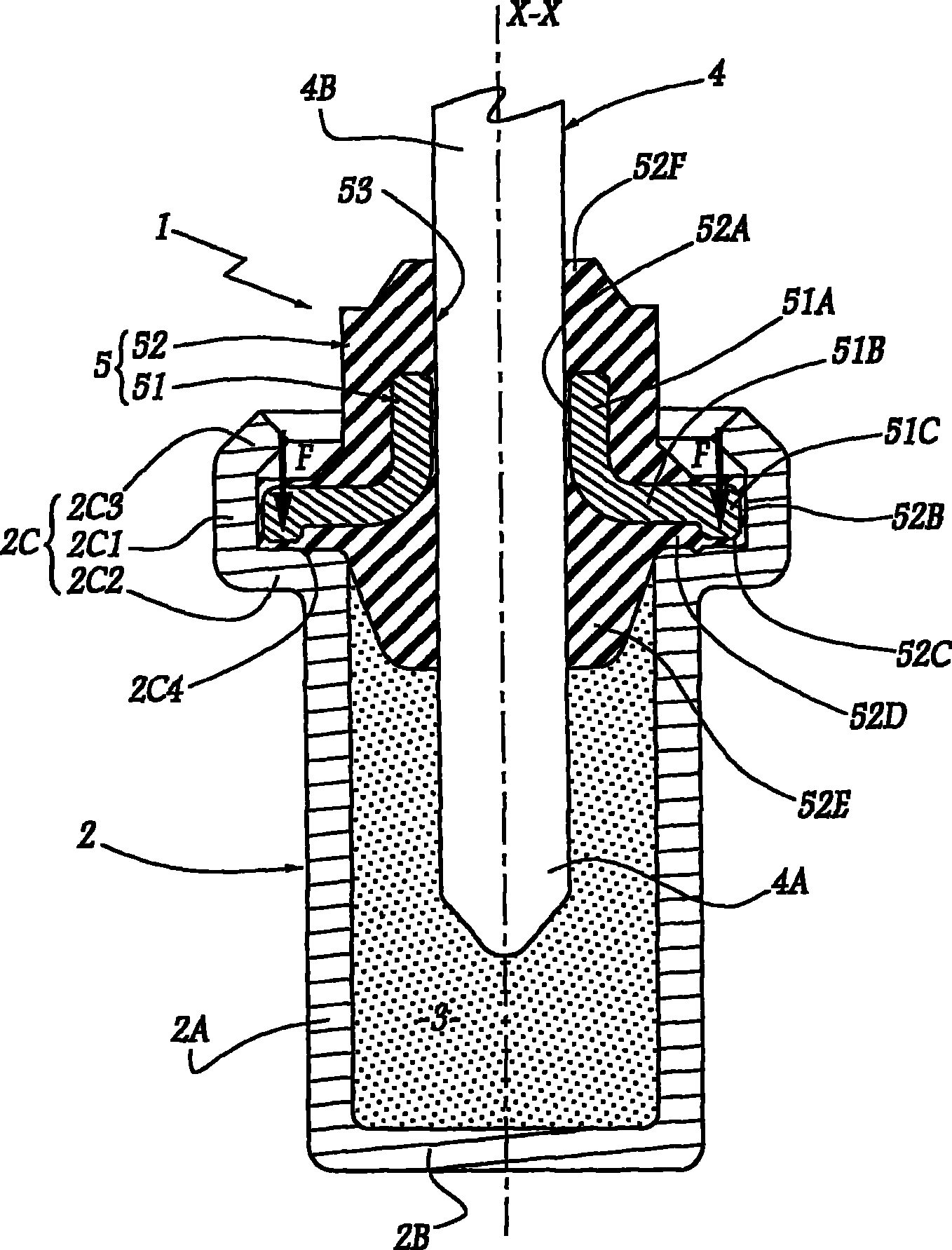

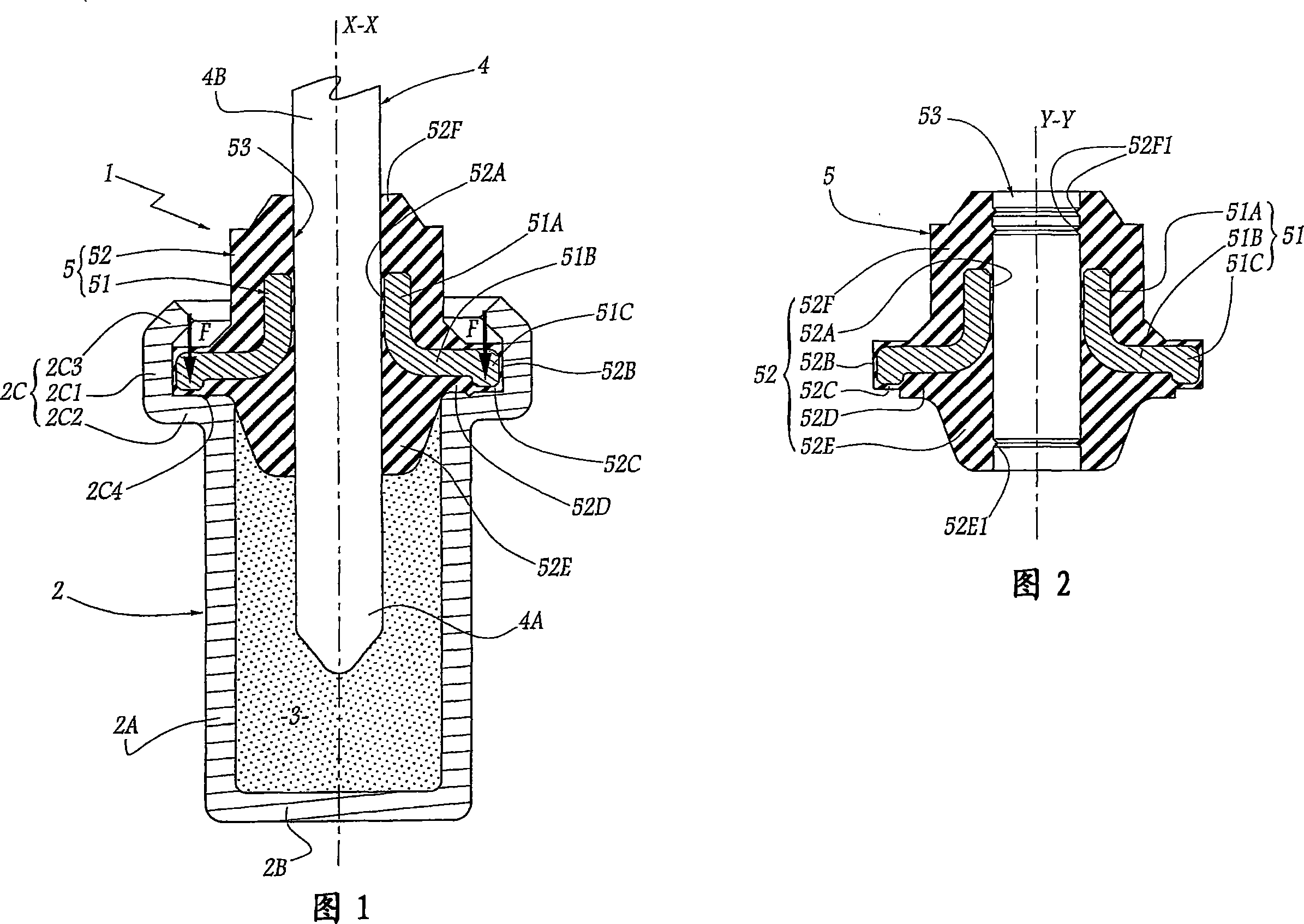

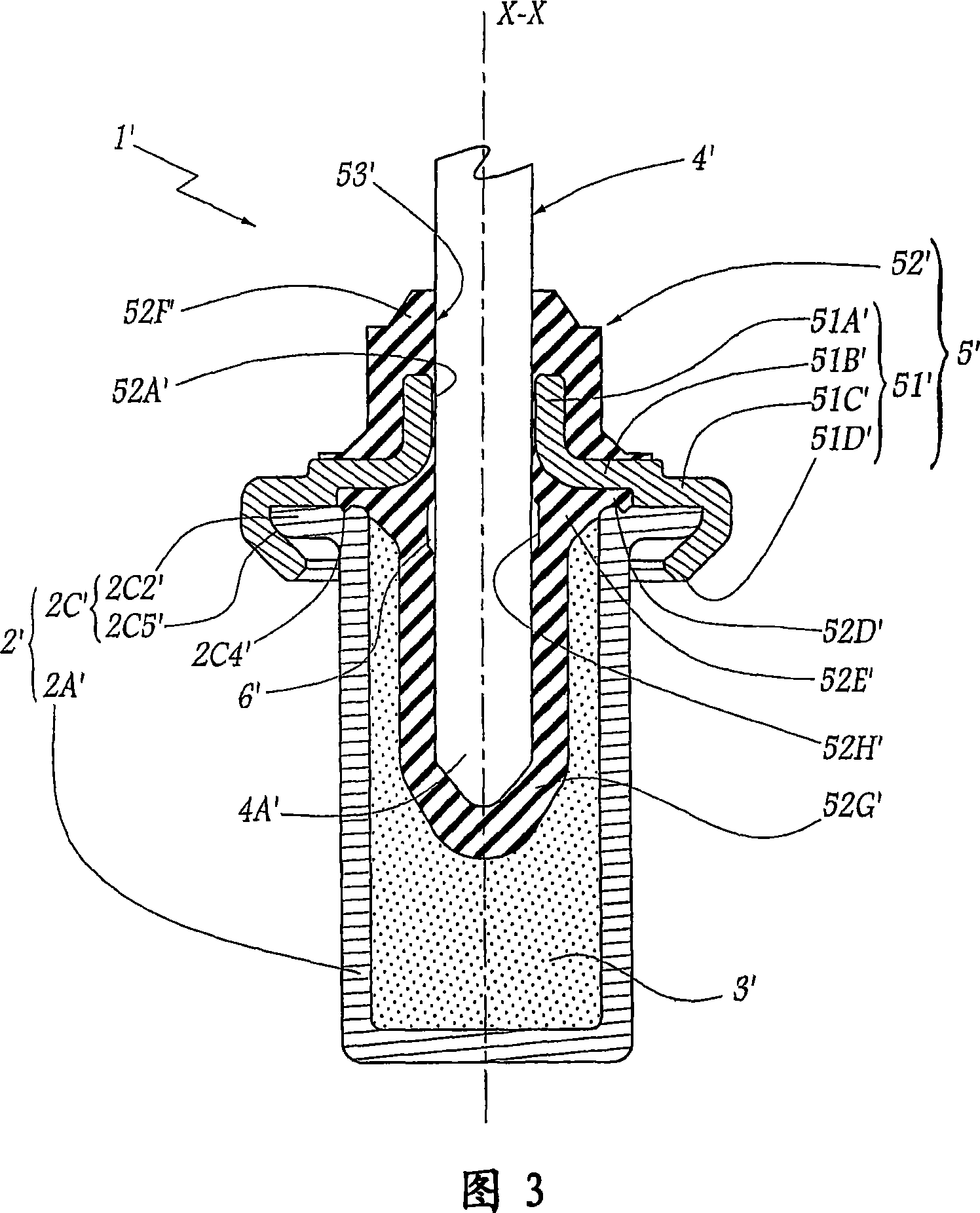

[0030] Figure 1 shows a thermostatic element 1 comprising:

[0031] - an approximately cylindrical metal cup 2 with a circular base and a longitudinal axis X-X,

[0032] - intumescent wax 3 stored in a cup 2, if necessary filled with a powder with good thermal conductivity, such as copper powder,

[0033] - a metal piston 4 generally cylindrical and substantially coaxial with the cup 2, one end 4A of which protrudes into the wax 3, the opposite end 4B of which is only partially shown; relative to the cup along axis X-X under the action of translation, and

[0034] - An integral assembly 5 adapted to guide the translation of the piston 4 relative to the cup 2 and to seal the wax 3 on the outside of the thermostatic element 1 .

[0035] For convenience, the remainder of the specification provides that the terms "lower" or "downward" refer to a direction towards the bottom of Figures 1 and 2, while the terms "top" and "upward" refer to the opposite direction. The same is true ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com