Flow pass and cavity wall integrated heat absorber with heat storage solar cavity

A technology of solar energy and heat absorbers, which is applied in the field of heat absorbers with heat storage solar cavity, can solve the problems that heat absorbers cannot be designed in an integrated manner, increase complexity and production costs, and achieve simple structure, convenient operation, light -Effect of high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

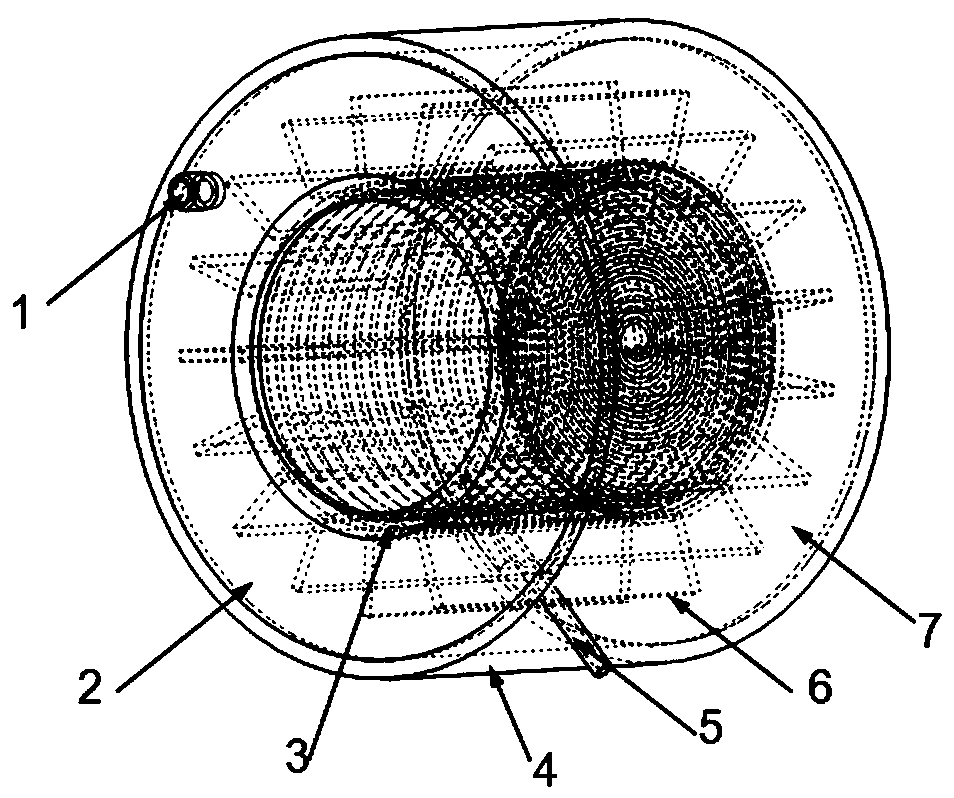

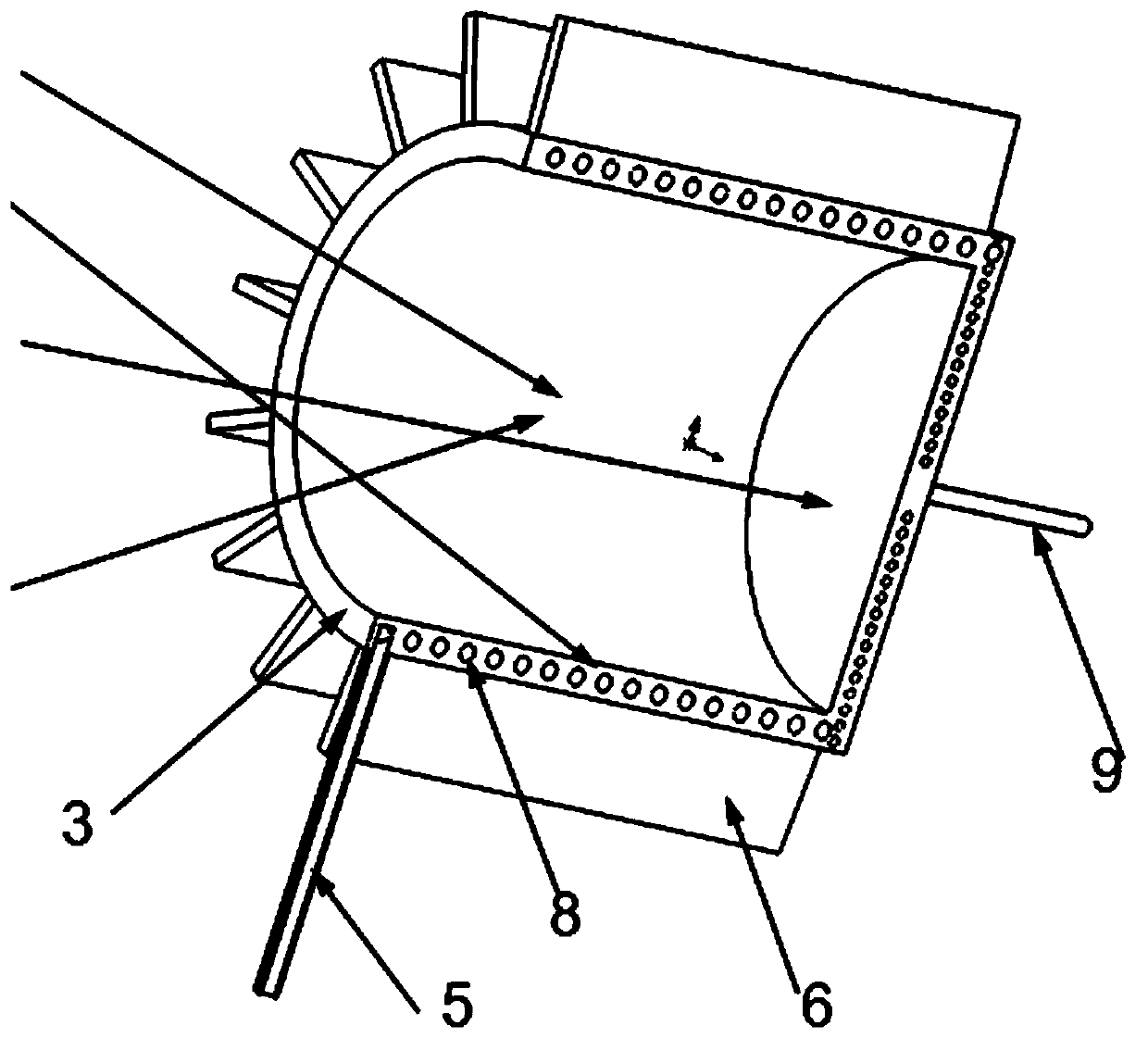

[0028] Such as figure 1 As shown, the present invention includes a front sealing plate 2 , a heat absorbing body 3 , a peripheral plate 4 , a working fluid inflow pipe 5 , a heat exchange fin 6 , a rear sealing plate 7 , a spiral channel hole 8 , and a working medium outflow pipe 9 . The heat absorber 3 is a cylindrical cavity structure with an opening at one end, and one end of the opening is used to receive solar light energy gathered by a solar concentrator, and a quartz glass plate is provided at the opening to reduce the heat absorber. 3 Radiative and convective heat loss. The inner surface of the heat absorber 3 is coated with a high-temperature-resistant coating that can efficiently absorb solar energy, and the outer side of the bottom plate is wrapped with an insulating material for reducing radiation and convective heat loss of the heat absorber 3 .

[0029] Such as figure 2 As shown, the side wall of the heat absorber 3 is provided with a spiral spiral channel hol...

Embodiment 2

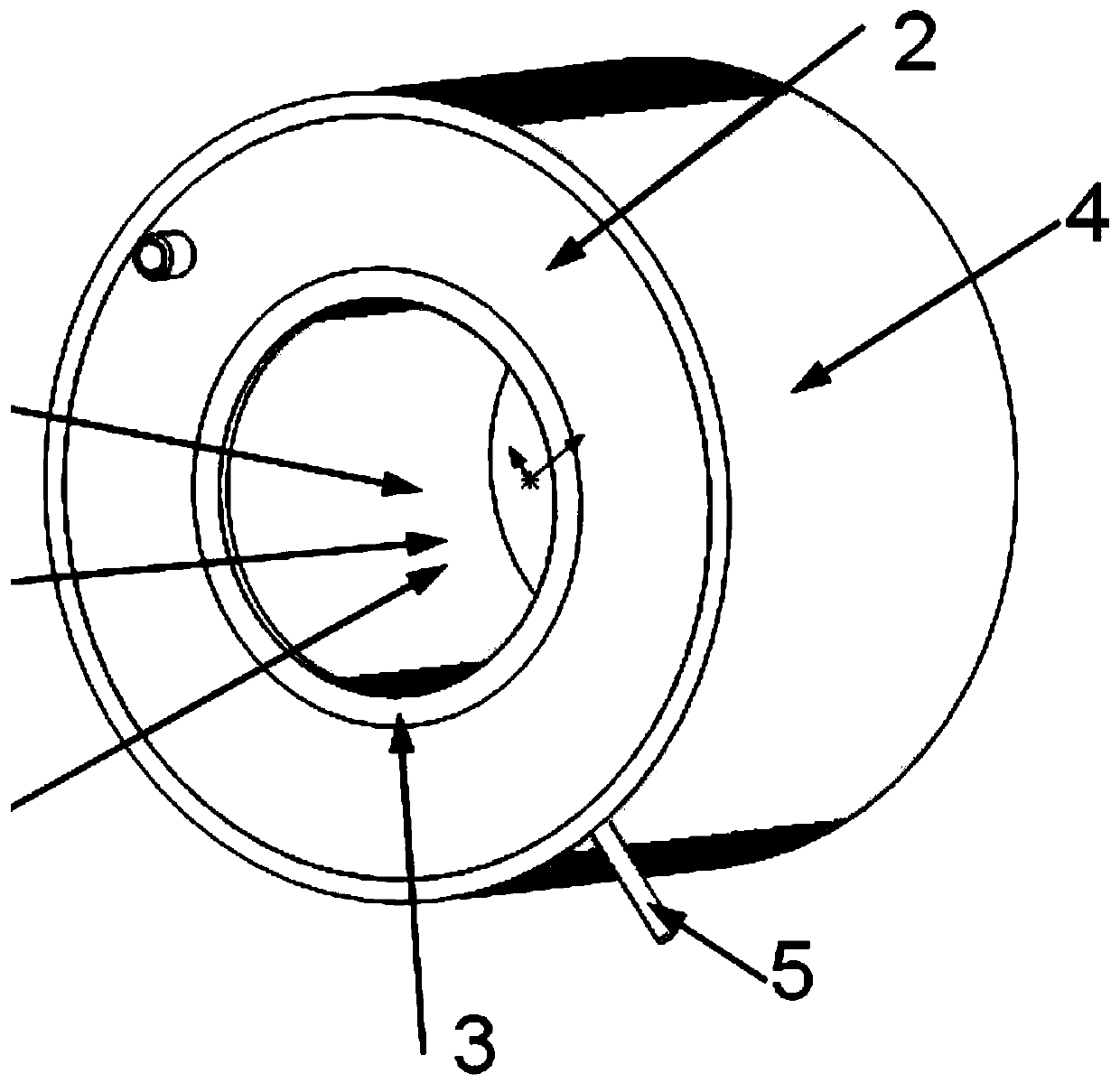

[0033] Such as Figure 4 As shown, the structure is similar to that of Embodiment 1, and its difference from Embodiment 1 lies in the structure of the heat absorber 3 . In this embodiment, the heat absorber 3 is composed of a tubular body 12 , a front cover 10 and a rear cover 11 , and is a cylindrical cavity structure with one end open.

[0034] The side wall of the tubular body 12 is provided with a plurality of vertical flow channel holes 13, and the plurality of vertical flow channel holes 13 are evenly distributed along the circumferential direction. The cross-sectional geometry of the vertical flow channel holes 13 can be circular, oval, rectangular and triangles etc.

[0035] The front end of the tubular body 12 is provided with a front cover 10 , and the rear end is provided with a rear cover 11 . The front cover 10 is an annular structure whose inner hole radius is less than or equal to the inner hole radius of the tubular body 12. The front cover 10 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com