Tire-type quick impact testing machine

An impact testing machine, tire-type technology, applied in the field of tire impact and friction coatings, can solve the problems of large difference, long acceleration and lifting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

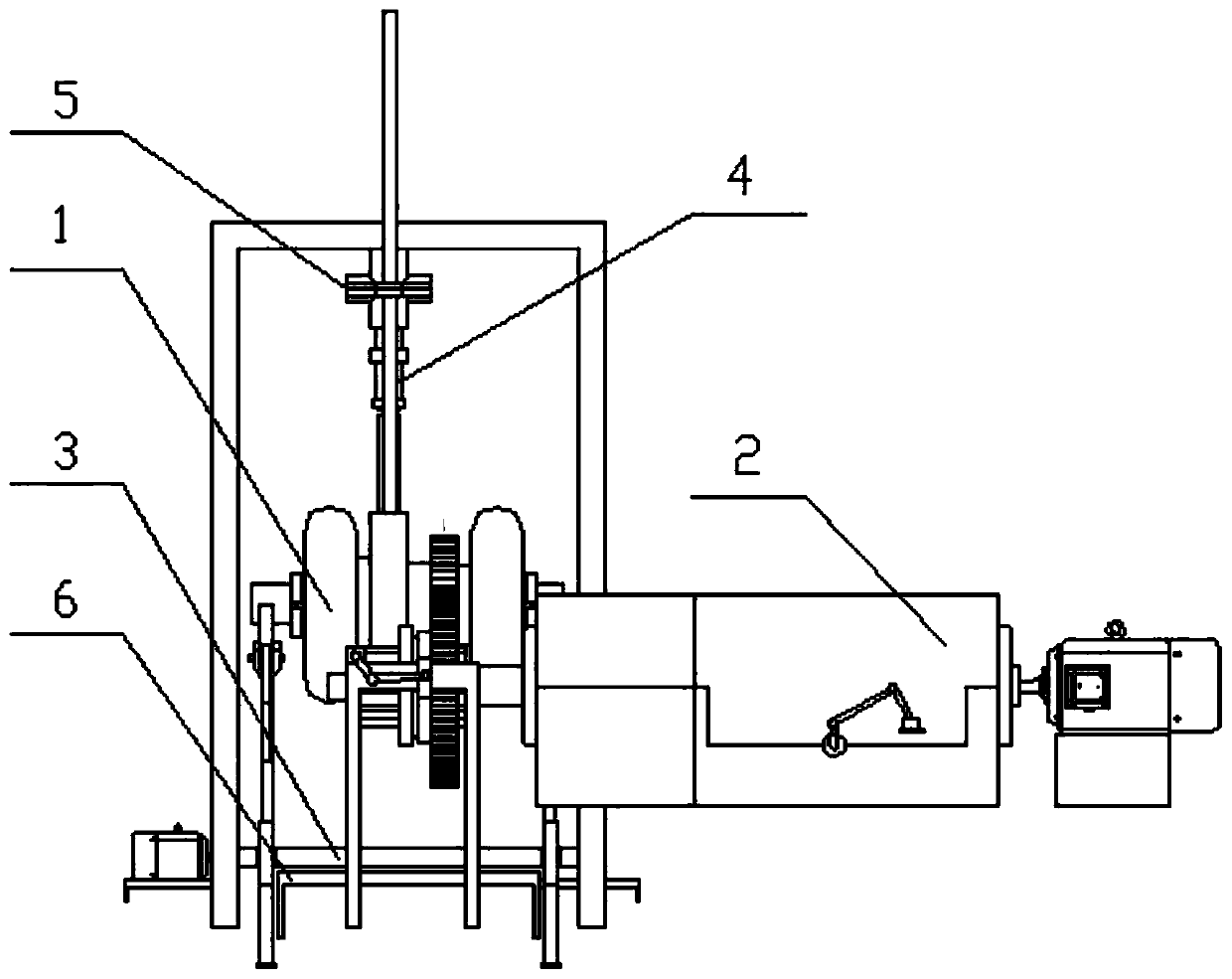

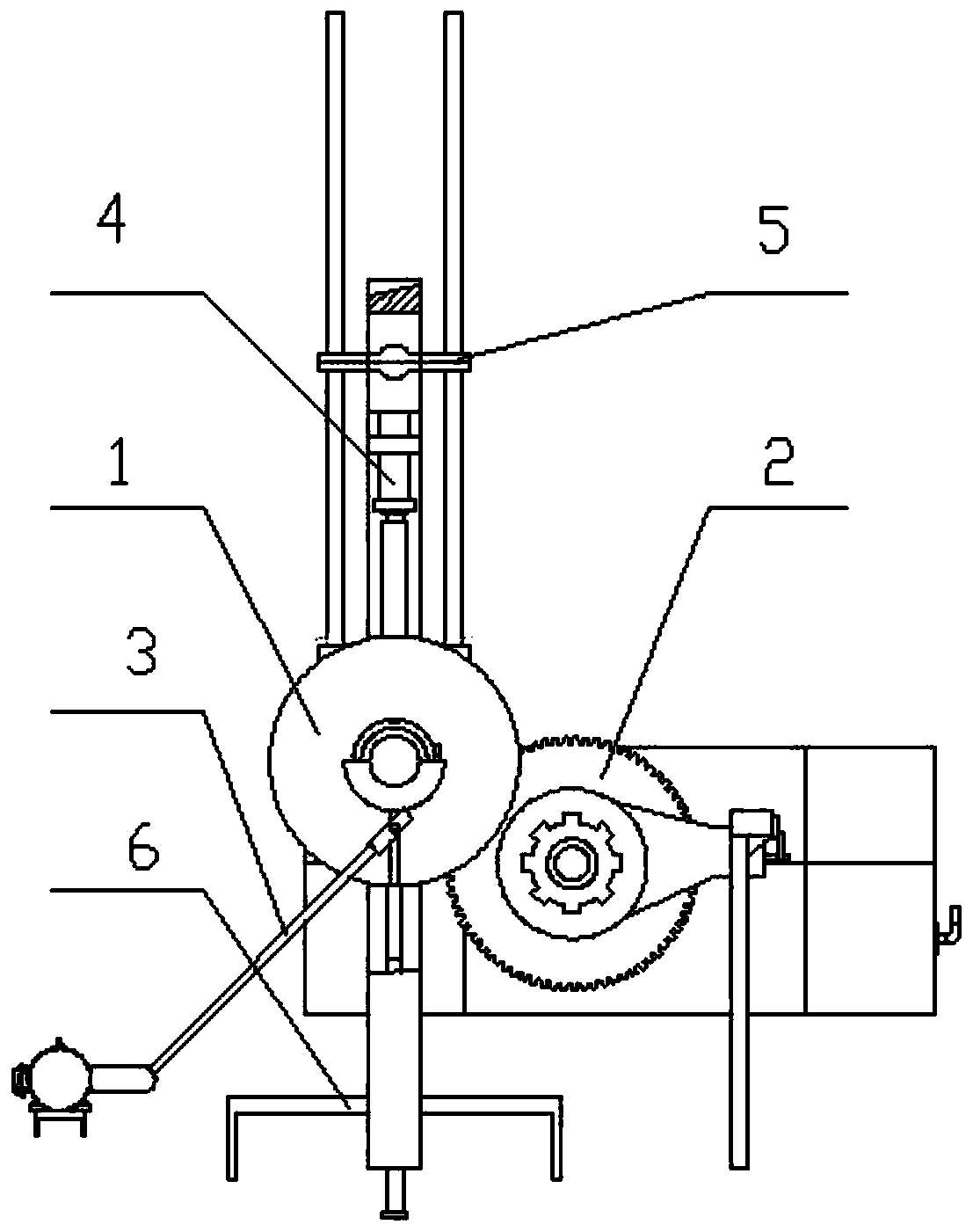

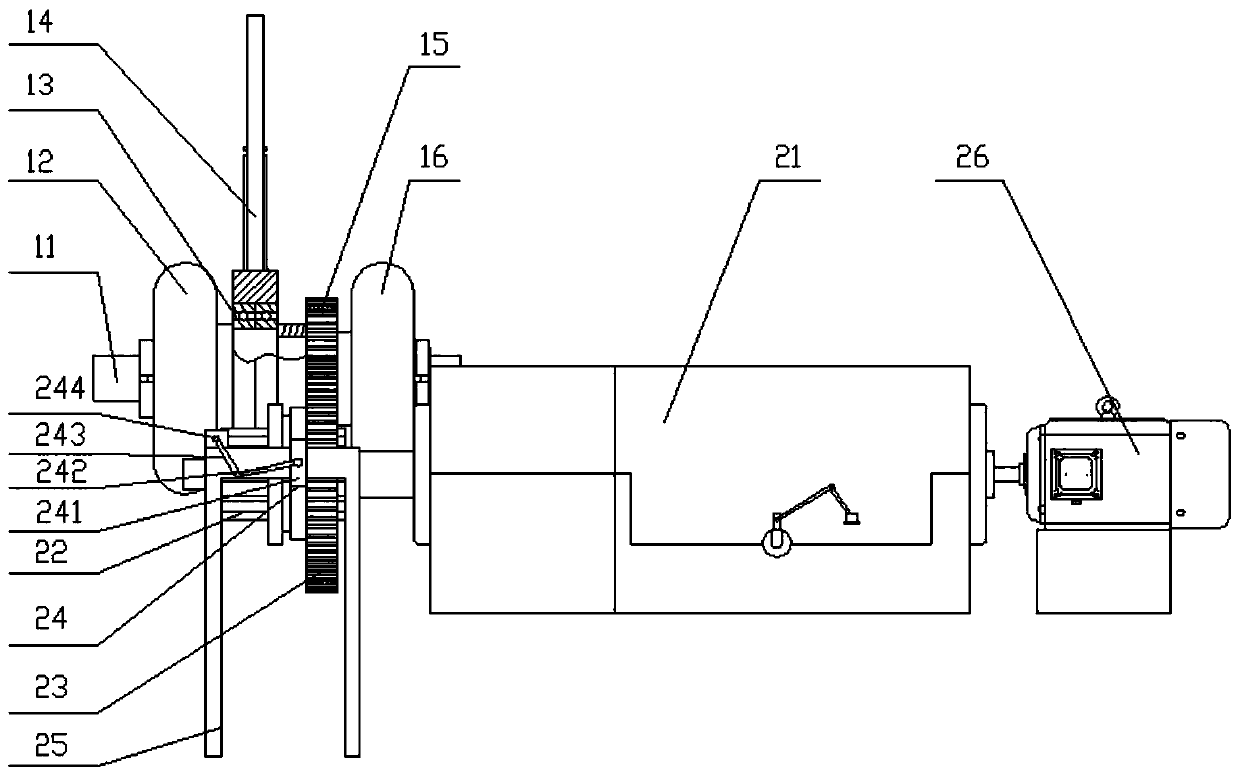

[0026] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, a tire-type rapid impact testing machine, including: impact device 1, acceleration device 2, lifting device 3, buffer device 4, Fixed ejection counterweight device 5, impact test bench 6, stepped shaft I11, tire 12I, bearing I13, bracket guide rod 14, spur gear I15, tire II16, transmission device 21, spline shaft 22, slip gear 23, Shift fork 24, bracket I25, motor I26, lower box 2101, upper box 2102, bearing II2103, cone wheel I2104, cone wheel II2105, input shaft I2106, bearing III2107, steel ball 2108, stepped shaft II2109, bearing seat I2110, Spur gear II2111, incomplete gear 2112, bevel gear I2113, bevel gear II2114, stepped shaft III2115, bearing seat II2116, input shaft II2117, bearing IV2118, crank handle 2119, transmission connecting rod 2120, transmission crank 2121,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com