A split type resonator with different impedance ratios

A split-type resonator and resonator technology, applied in the field of resonators, can solve problems such as not being able to meet the requirements of power capacity, and achieve the effects of increasing the perimeter-area ratio, suppressing high-order harmonics, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are preferred embodiments of the present invention, but the protection scope of the present invention is not limited thereby.

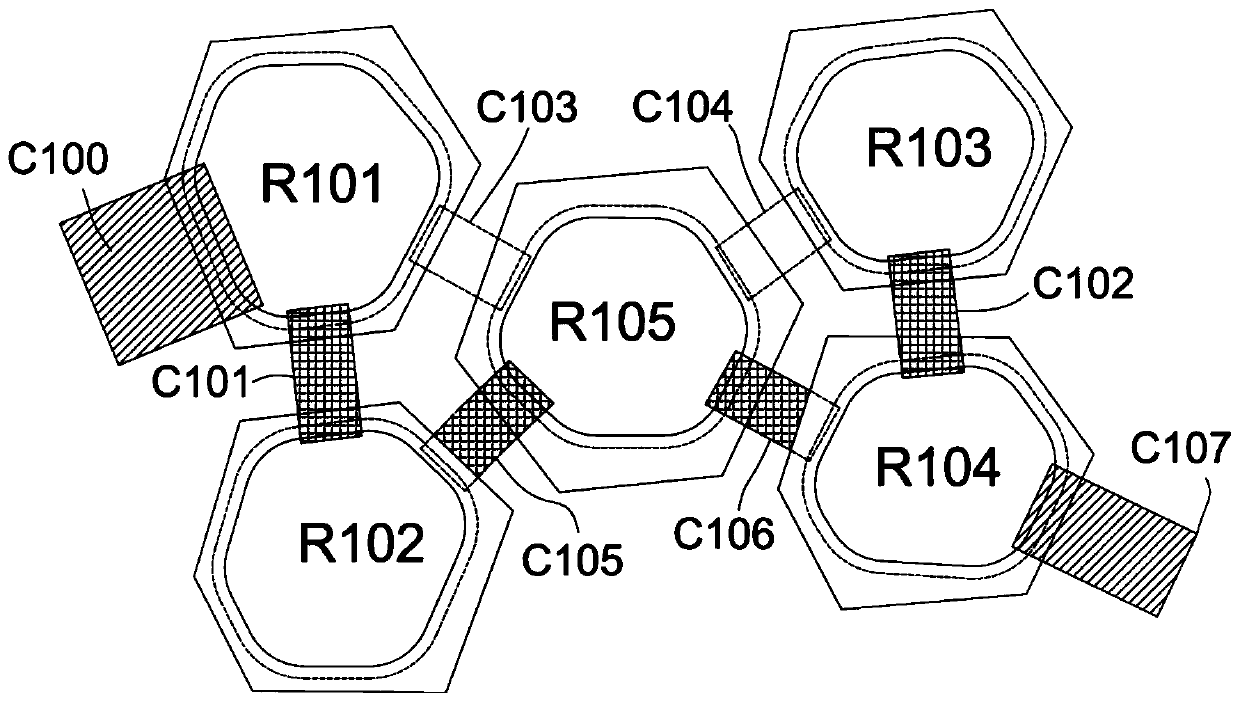

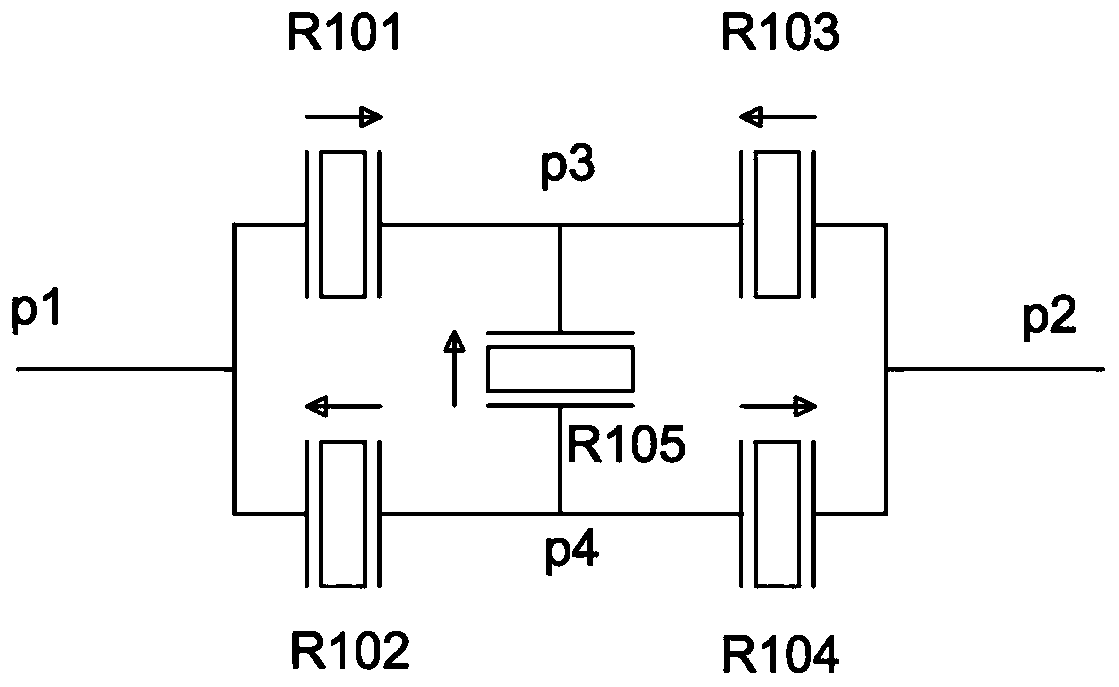

[0033] Figure 1A is a schematic diagram of the structure of the first split resonator according to an embodiment of the present invention. Such as Figure 1A As shown, in the embodiment of the present invention, the traditional single resonator is split into five sub-resonators, and the five sub-resonators are the first resonator R101, the second resonator R102, the third resonator R103, The fourth resonator R104 and the fifth resonator R105.

[0034] Figure 1A The specific connection mode of the 5 resonators is given, which will be described in detail below.

[0035] The upper electrode of the first resonator R101 has a pin C100, and the upper electrode of the first resonator R101 is electrically connected to the upper electrode of the second resonator R102 C101; the lower electrode of the first resonator R101 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com