Equipment capable of producing multiple explosive composite metal sheets at the same time and method of using the same

A composite metal and plate technology, applied in the field of explosive composite, can solve the problems of high operation and equipment requirements, large environmental pollution, poor economic benefits, etc., and achieve the effects of high production efficiency, reduced pollution, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

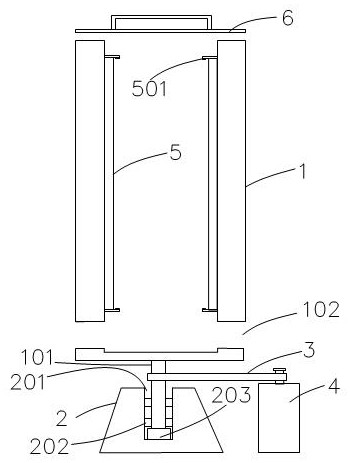

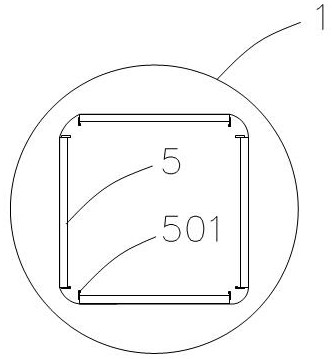

[0043] Such as Figure 1-2 As shown, a device that can prepare multiple explosive composite metal sheets at the same time, including: explosive composite drum 1, base 2, transmission device 3 and motor 4;

[0044] The equipment capable of preparing a plurality of explosive composite metal sheets at the same time is a bottom-closed vertical drum, and its inner wall is uniformly provided with four explosive composite surfaces 5 parallel to the axis, the explosive composite surfaces 5 are planes, and the explosive composite surfaces Clamping devices 501 are provided at the four corners, and a shaft 101 is provided at the center of the bottom of the explosive composite drum 1; the clamping device 501 is a fastener with an angle steel, and the four corners of the composite metal plate are held tightly by the angle steel to achieve the purpose of fixing; The pre-plywood is attached to the explosive composite surface so that it can be stably stressed, and the pre-plywood is fixed by ...

Embodiment 2

[0052] A method for simultaneously preparing multiple explosive composite metal sheet devices, comprising the following steps:

[0053] S1. Surface polishing treatment: Surface polishing treatment is carried out on the base plate and double board respectively; if there is an interlayer metal plate, both sides of the interlayer metal plate are polished;

[0054] S2. Pre-assembly: Align the base plate with the doubler plate, weld and pre-fix at the four corners to make a pre-laminated plate; if the clamping position of the clamping device 501 exceeds the upper surface of the doubler plate during clamping, it may affect the explosive compounding In order to keep the plate firmly on the explosive composite surface 5 and make the clamping position of the clamping device below the double plate, the base plate and the double plate must be pre-assembled.

[0055] S3. Explosive distribution: Lay explosives on the compound board, the thickness of the explosives is 18mm;

[0056] S4. Inst...

Embodiment 3

[0066] Similar to Example 1, the difference lies in that the explosive composite surface is a curved surface, so as to prepare the explosive composite board with the base plate and doubler board as curved surfaces, and meanwhile, the explosive board should also be prefabricated into a suitable curved surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com