Automatic double-end sawing machine for processing chopping board

A sawing machine and cutting board technology, which is applied to sawing components, sawing equipment, wood processing appliances, etc., can solve problems such as affecting the right angle of the cutting surface and both sides, achieve fully automatic flow operations, and eliminate irregularities of cutting boards. , the effect of reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

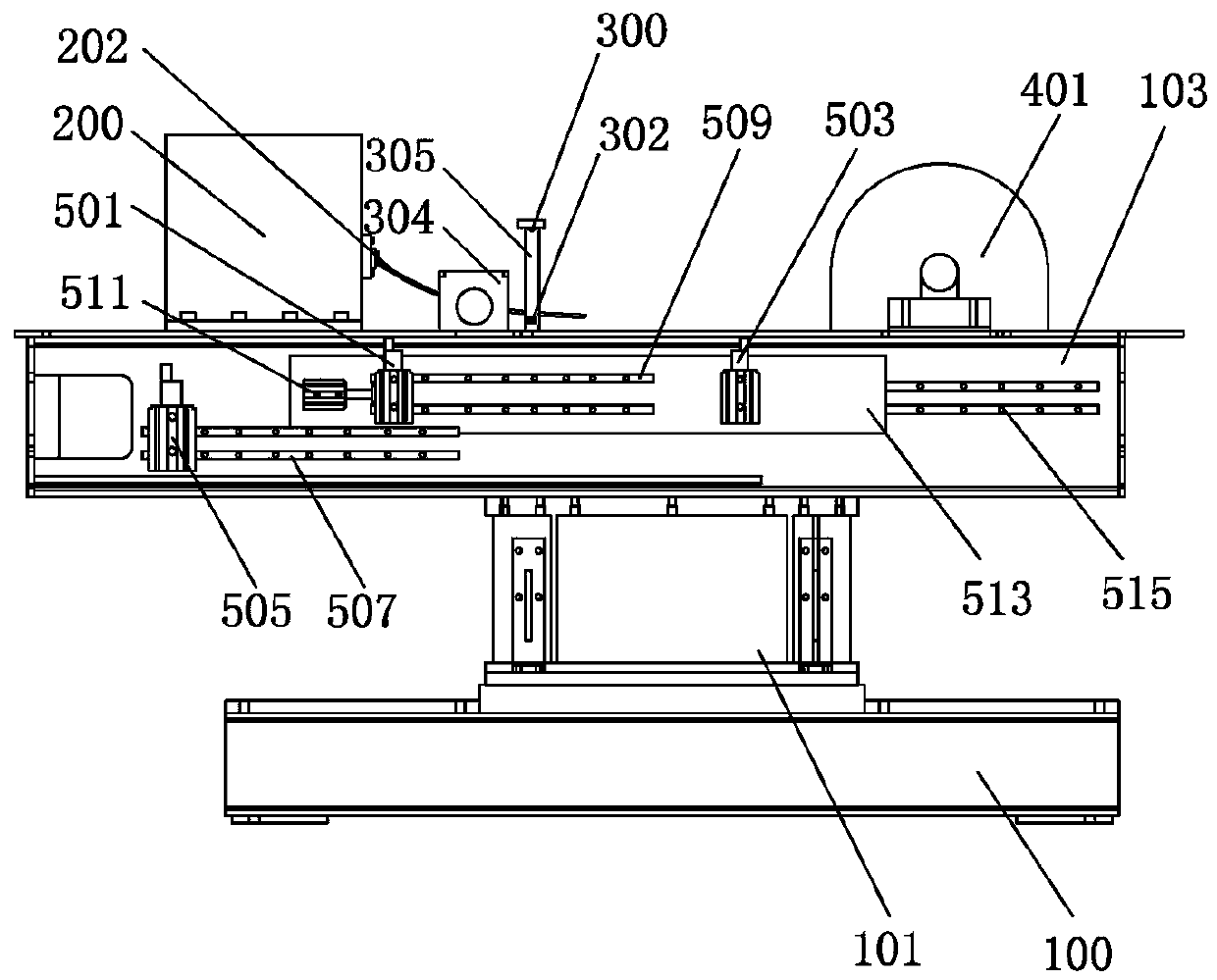

[0041] Referring to the accompanying drawings, a specific example will be used to further explain the structure and working principle of the automatic double-end sawing equipment of the present invention.

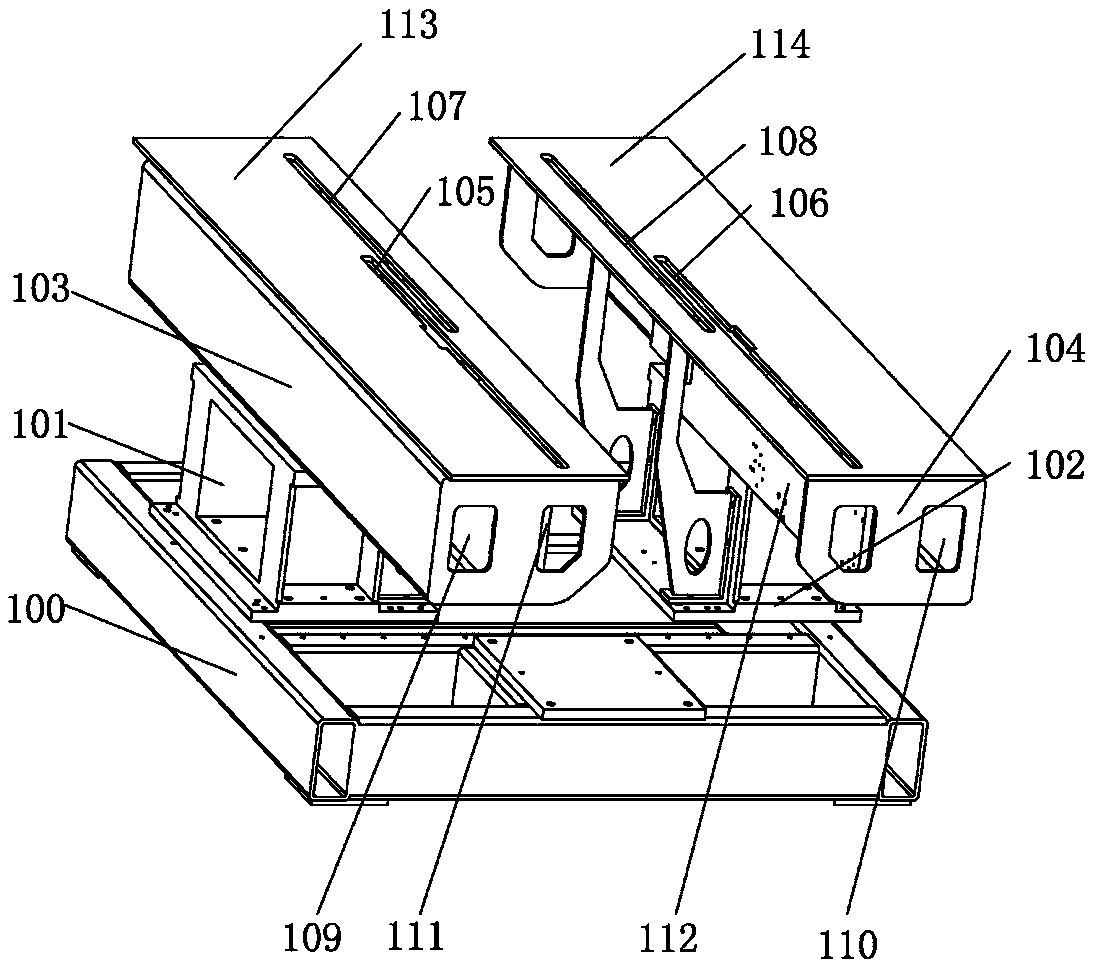

[0042] Such as figure 1 The shown frame includes a base 100, a left support frame 101, a right support frame 102, a left workbench 103, and a right workbench 104. The left and right workbenches are each provided with a wiring warehouse for placing electrical circuits and pneumatic pipelines, and for installing slides. The frame wall of rail and the worktop supporting cutting board are respectively left wiring warehouse 109, right wiring warehouse 110, left frame wall 111, right frame wall 112, left side worktop 113 and right side worktop 114.

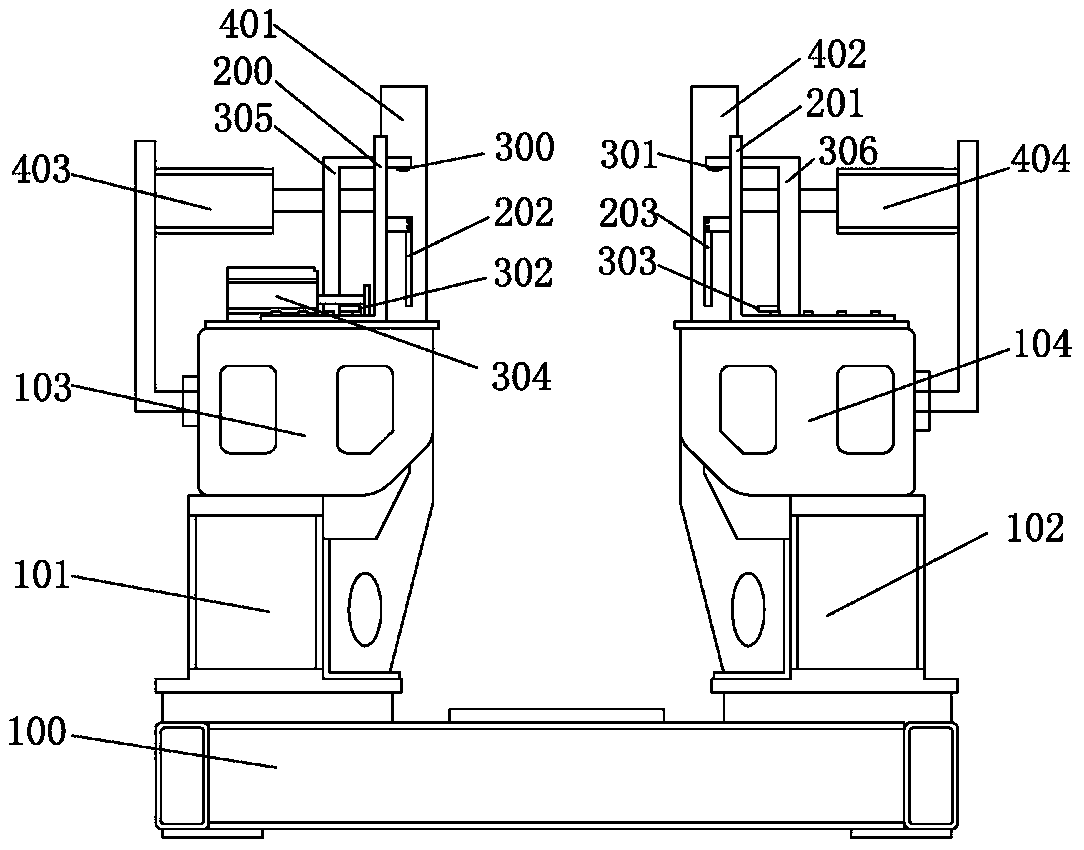

[0043] Taking the conveying direction of the chopping board as the front, the frame is from the back to the front, and the cutting board placement station, the cutting board lateral position adjustment station, and the sawing station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com