Quick dismounting machine for deep cavity and belt column plastic products from correcting assistive devices

A deep cavity, dismantling machine technology, applied in the coating and other directions, can solve the problems of easily damaged products, poor insertion, long time consumption, etc., to ensure the balance of force, prevent scratched products, and avoid the effect of tilting again.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following will be combined with the accompanying drawings and preferred embodiments to describe a kind of deep cavity and post-type plastic product correction aids proposed according to the present invention. Its specific embodiment, structure, feature and effect thereof of quick disassembly machine are as follows in detail.

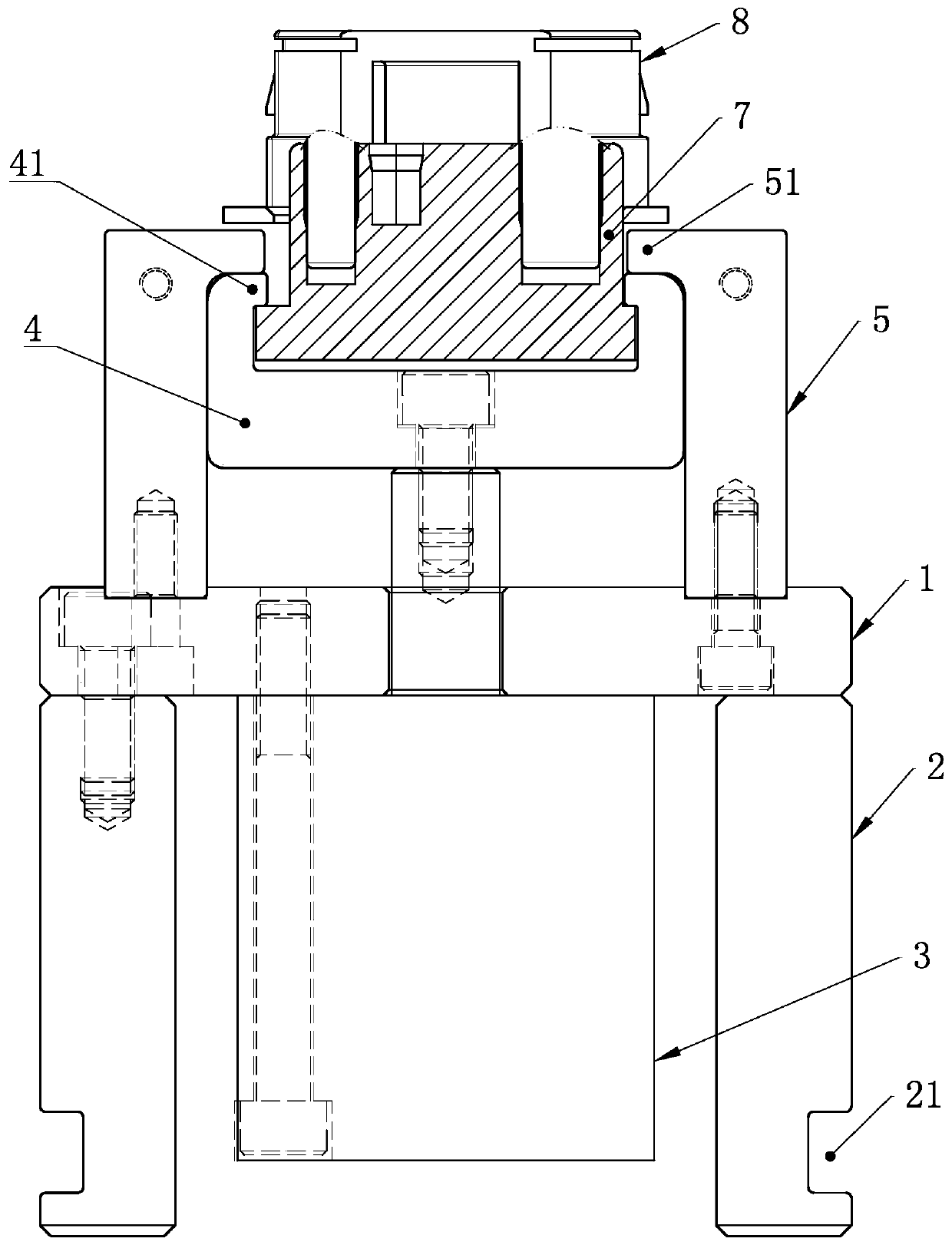

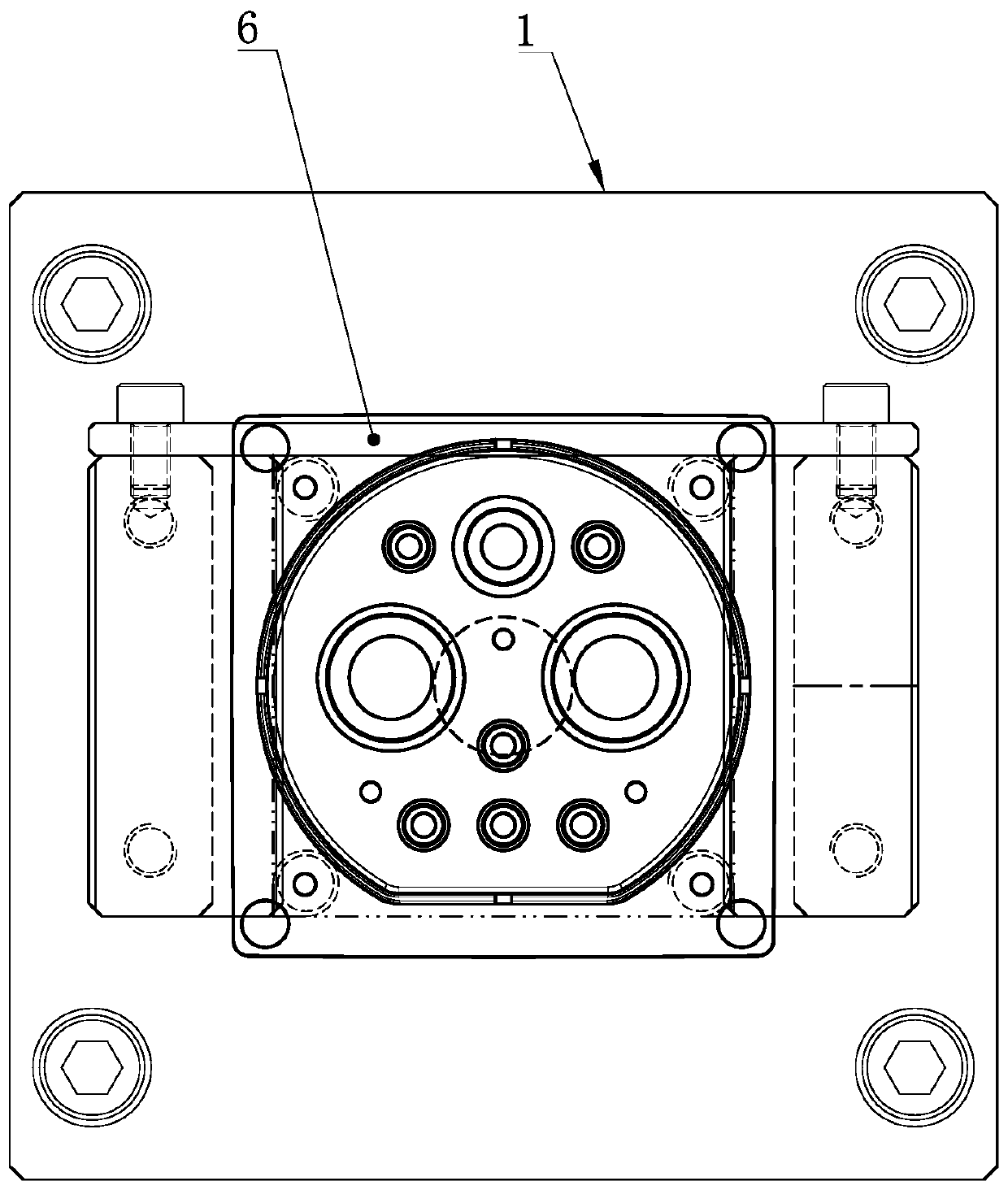

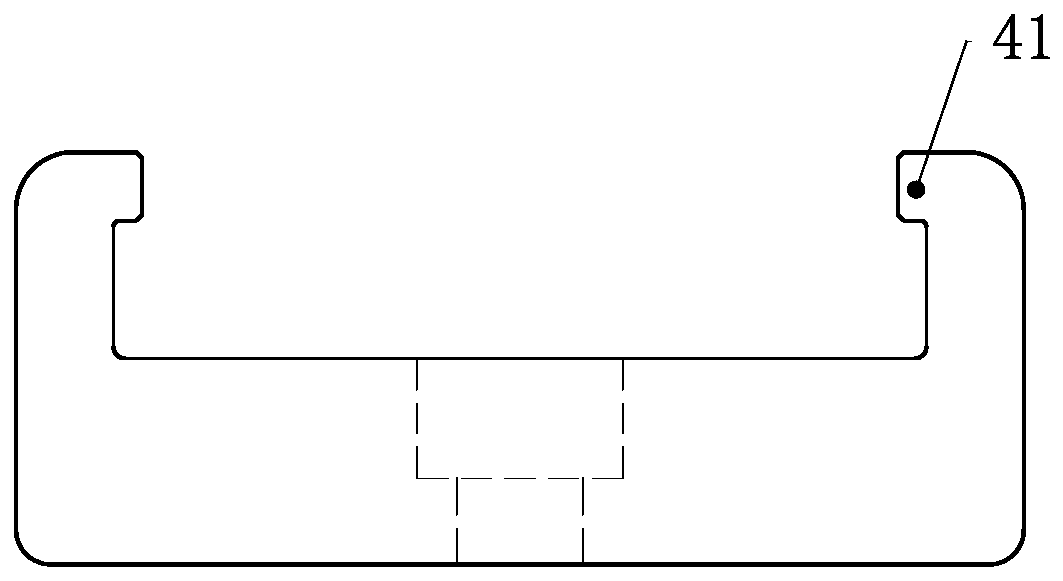

[0021] see Figure 1 to Figure 2 , a quick dismantling machine for correcting aids for deep cavity and plastic products with columns according to the present invention, which is used to quickly and non-injuryly separate orthodontic aids from deep cavity and plastic products with columns, which includes a bottom plate 1, the Both sides of the bottom of the bottom plate 1 are symmetrically installed with two brackets 2 through bolts, and the outer side of the bracket is provided with a fixing groove 21 along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com